Method for polishing copper by chemical and mechanical methods

A chemical-mechanical and main grinding technology, used in grinding equipment, grinding machine tools, electrical components, etc., can solve problems such as prolonged copper corrosion, affecting the electrical performance and stability of semiconductor devices, and copper interconnection defects, and achieve good corrosion inhibition. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

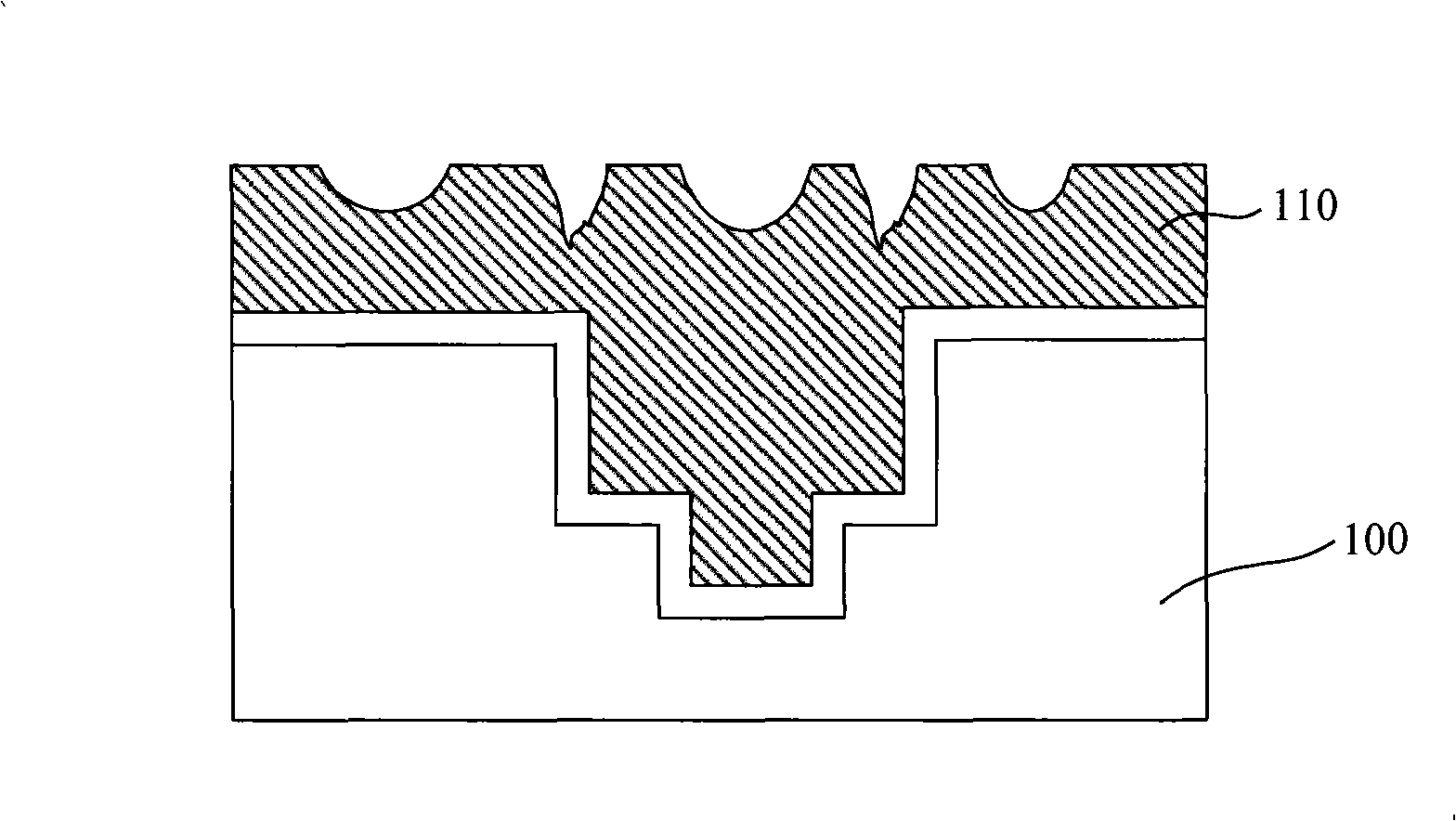

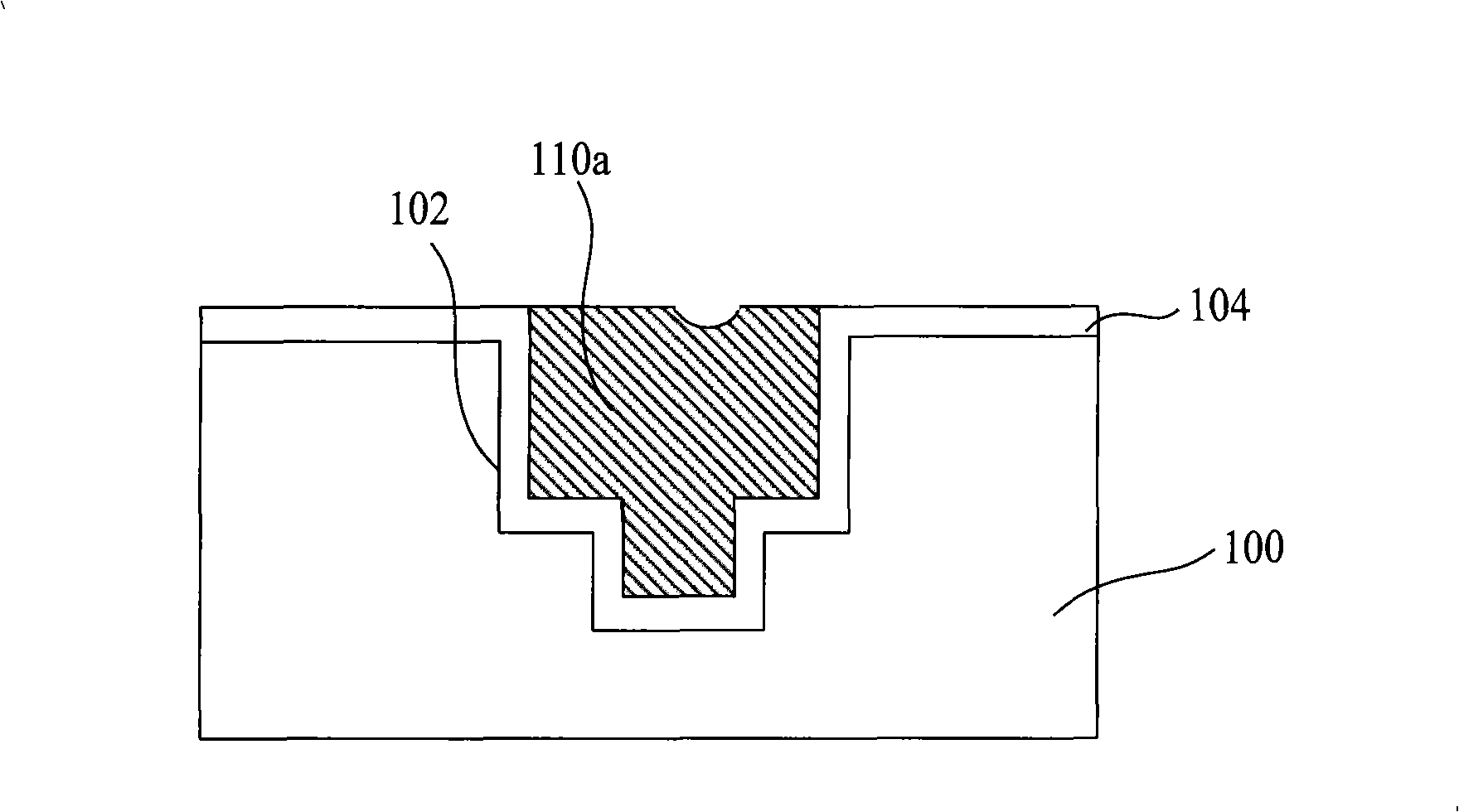

[0056] Figure 5 It is the flowchart of the method embodiment of copper chemical mechanical polishing of the present invention, Figure 6 is a schematic cross-sectional view of a semiconductor substrate with a copper metal layer, Figure 7 to Figure 9 It is a schematic cross-sectional view of the semiconductor substrate structure corresponding to each step of the embodiment of the copper chemical mechanical polishing method of the present invention.

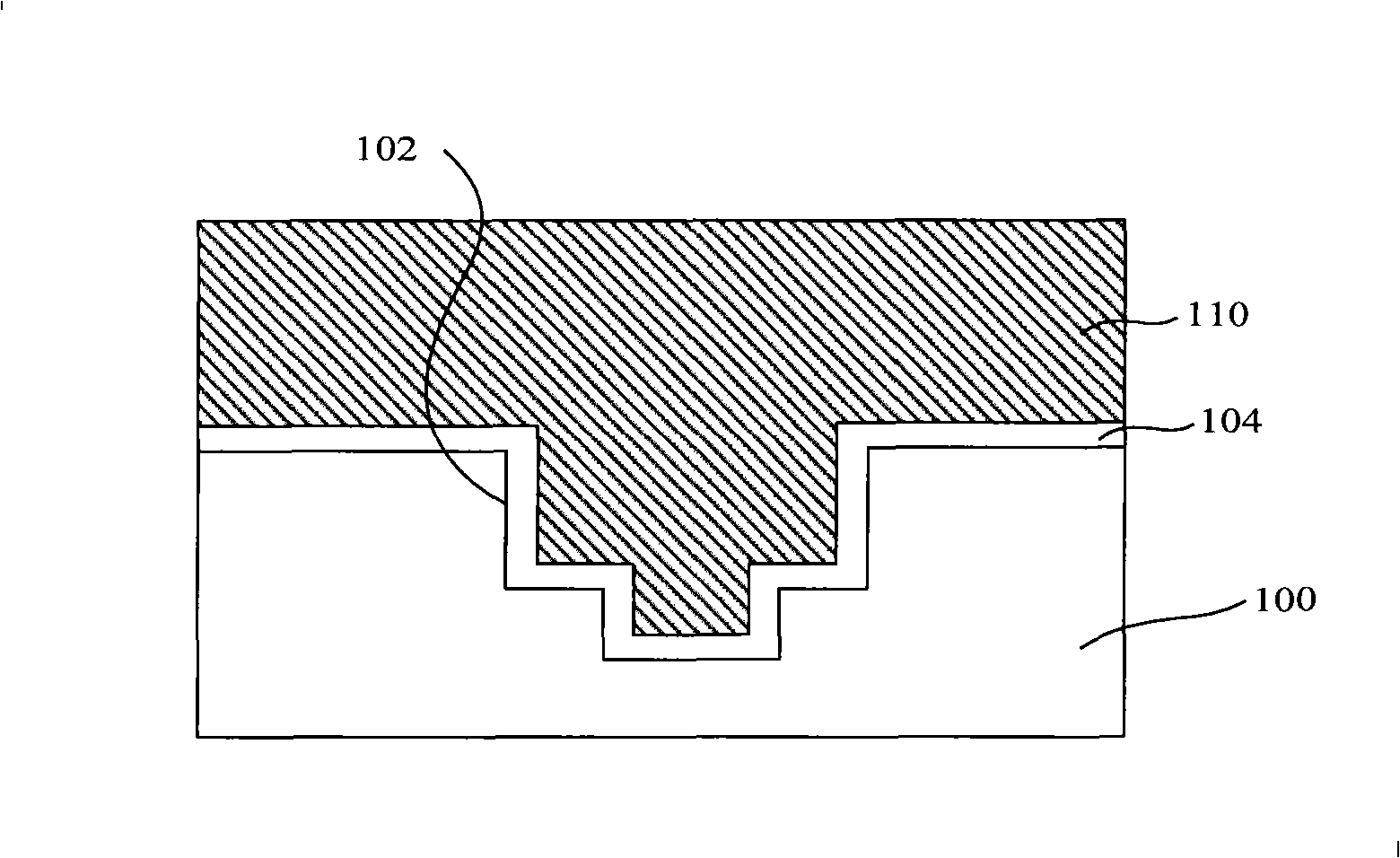

[0057] Such as Figure 6As shown, a semiconductor substrate 10 to be ground is provided, with a copper metal layer 16 on the semiconductor substrate 10, with an opening 12 in the semiconductor substrate 10, the copper metal layer fills the opening 12, and in the There is a barrier layer 14 between the copper metal layer 12 and the semiconductor substrate 10 .

[0058] Wherein, the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com