Biodegradable non-phosphorous anti-scale corrosion inhibitor and preparation method thereof

A phosphorus-free scale inhibition and biodegradation technology, applied in chemical instruments and methods, scale removal and water softening, water/sludge/sewage treatment, etc., can solve problems such as no field application conclusions, and achieve the goal of reducing treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

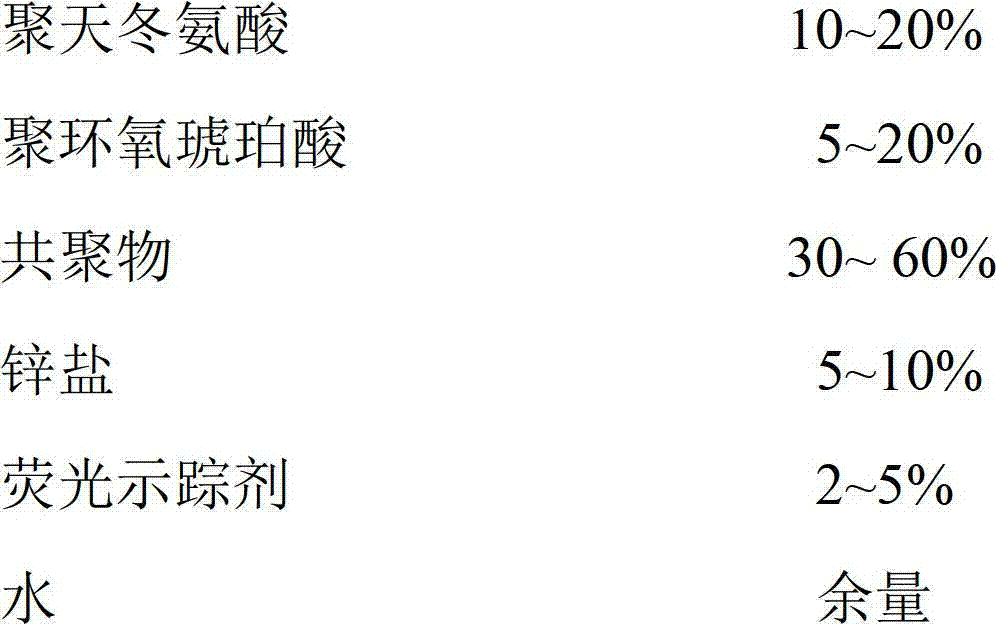

[0030] Select raw materials according to mass percentage:

[0031]

[0032]

[0033] Water 130g, maleic anhydride / acrylic acid / acrylic acid hydroxylactone / 2-acrylamido-2-methylpropanesulfonic acid tetrapolymer (molecular weight 2000-10000, monomer maleic anhydride, acrylic acid in tetrapolymer The mass ratio of hydroxylactone acrylate and 2-acrylamido-2-methylpropanesulfonic acid is 2:6:1:1. The preparation method refers to: Liu Xiang et al., Synthesis of MAHA tetrapolymer and its scale inhibition Performance, Modern Chemical Industry, 29 (7), 2009.7;) 600g, zinc chloride 50g, polyepoxysuccinic acid (molecular weight 700-800, quality standard HG / T3823-2006, produced by Shanghai Meijing Environmental Protection Material Co., Ltd.) 100g, Polyaspartic acid (molecular weight 4000-5000, quality standard HG / T3822-2006, produced by Shijiazhuang Desai Chemical Co., Ltd.) 100g, fluorescent tracer (carboxysulfonaphthalimide) 20g were added to the reaction kettle in turn , stirred...

Embodiment 2

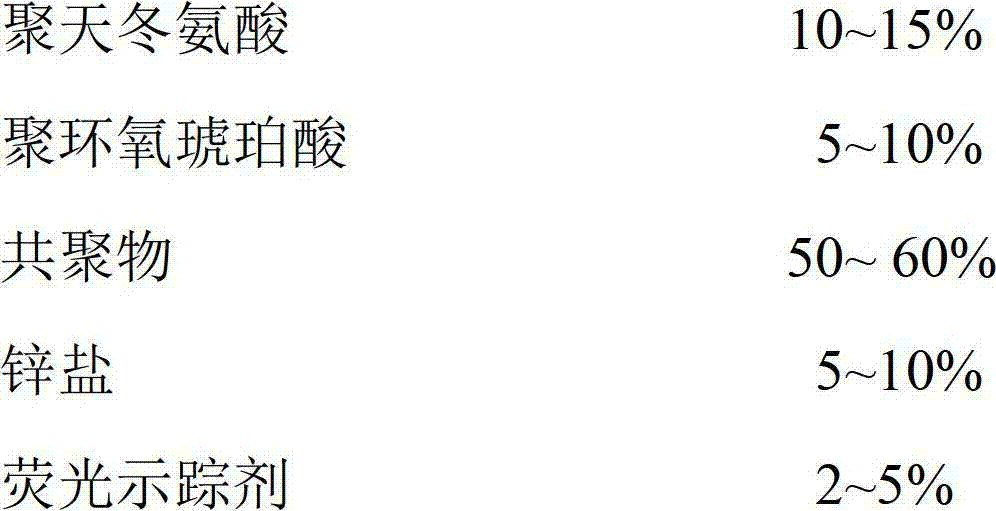

[0035] Select raw materials according to mass percentage:

[0036]

[0037] Water 85g, maleic anhydride / acrylic acid / acrylic acid hydroxylactone / 2-acrylamido-2-methylpropanesulfonic acid tetrapolymer (molecular weight 2000-10000, monomer maleic anhydride, acrylic acid in tetrapolymer The mass ratio of hydroxylactone acrylate and 2-acrylamido-2-methylpropanesulfonic acid is 2:6:1:1, and the preparation method is the same as in Example 1) 600g, zinc sulfate heptahydrate 95g, polyepoxysuccinate Acid (molecular weight 700-800, quality standard HG / T3823-2006, produced by Shanghai Meijing Environmental Protection Materials Co., Ltd.) 75g, polyaspartic acid (molecular weight 4000-5000, quality standard HG / T3822-2006, Shijiazhuang Desai Chemical Co., Ltd. Produced by the company) 125g, fluorescent tracer (carboxysulfonyl naphthalimide) 20g were added to the reaction kettle in turn, and stirred at 30~35℃ for 1~1.5 hours to obtain a biodegradable phosphorus-free scale inhibitor Etch...

Embodiment 3

[0039] Select raw materials according to mass percentage:

[0040]

[0041]Water 165g, maleic anhydride / acrylic acid / acrylic acid hydroxylactone / 2-acrylamido-2-methylpropanesulfonic acid tetrapolymer (molecular weight 2000-10000, monomer maleic anhydride, acrylic acid in tetrapolymer The mass ratio of hydroxylactone acrylate and 2-acrylamido-2-methylpropanesulfonic acid is 2:6:1:1, and the preparation method is the same as in Example 1) 550g, zinc sulfate monohydrate 65g, polyepoxysuccinate Acid (molecular weight 700-800, quality standard HG / T3823-2006, produced by Shanghai Meijing Environmental Protection Materials Co., Ltd.) 50g, polyaspartic acid (molecular weight 4000-5000, quality standard HG / T3822-2006, Shijiazhuang Desai Chemical Co., Ltd. Produced by the company) 150g, fluorescent tracer (carboxysulfonaphthalimide) 20g were sequentially added to the reaction kettle, stirred at 30~35℃ for 1~1.5 hours, and the biodegradable phosphorus-free scale inhibitor Etching age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com