Corrosion inhibitor applied to SCAL type indirect cooling system and chemical adding method of corrosion inhibitor

A corrosion inhibitor and cold system technology, which is applied in the field of material corrosion protection, can solve the problems of power plant operators' health hazards, high cost of water change treatment, waste of resources, etc., to reduce the damage to the ecological environment and the health damage of operators , Reduce waste of water resources, slow down the effect of decommissioning corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

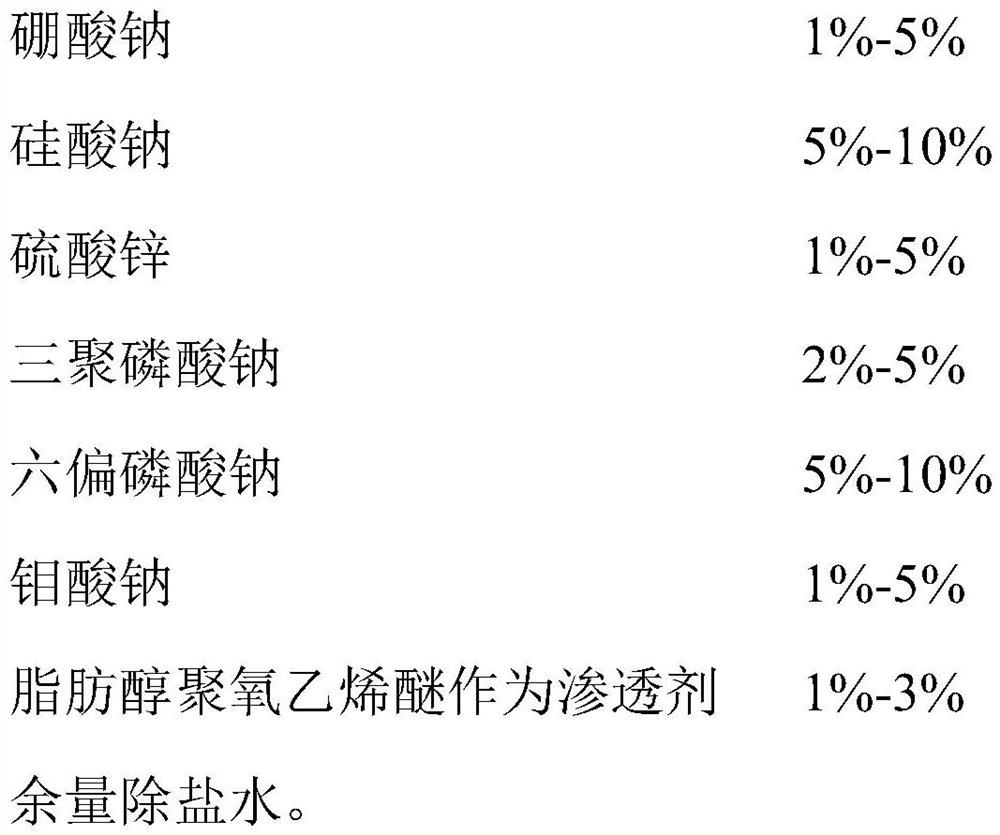

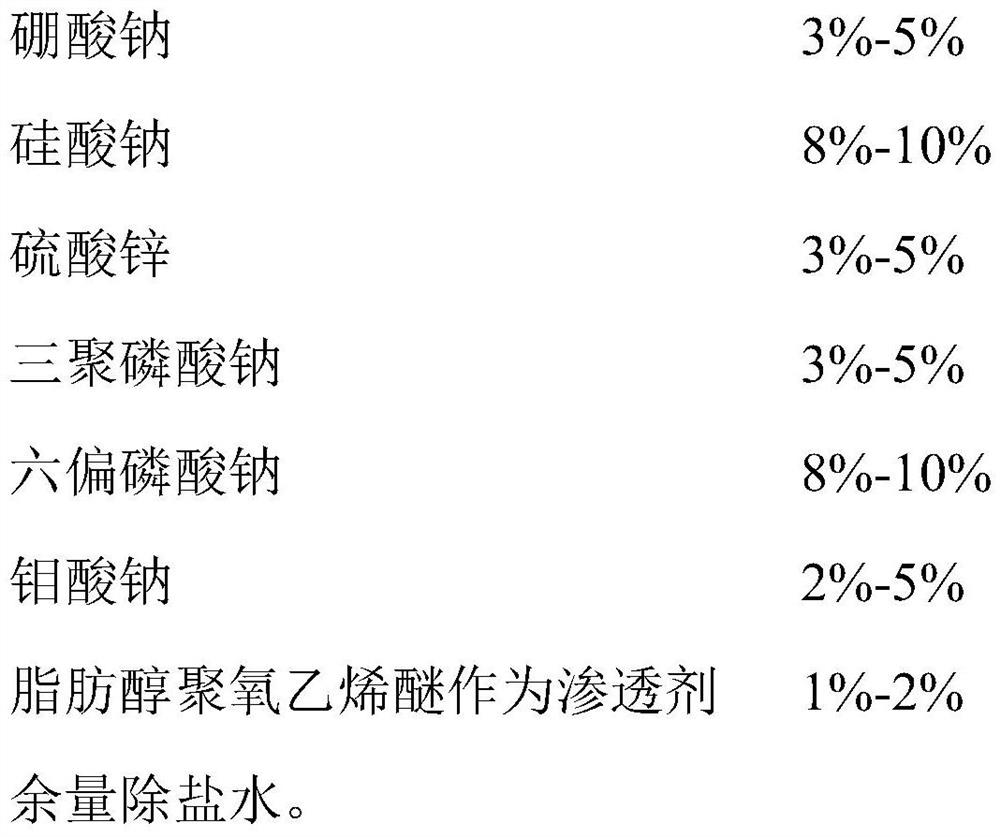

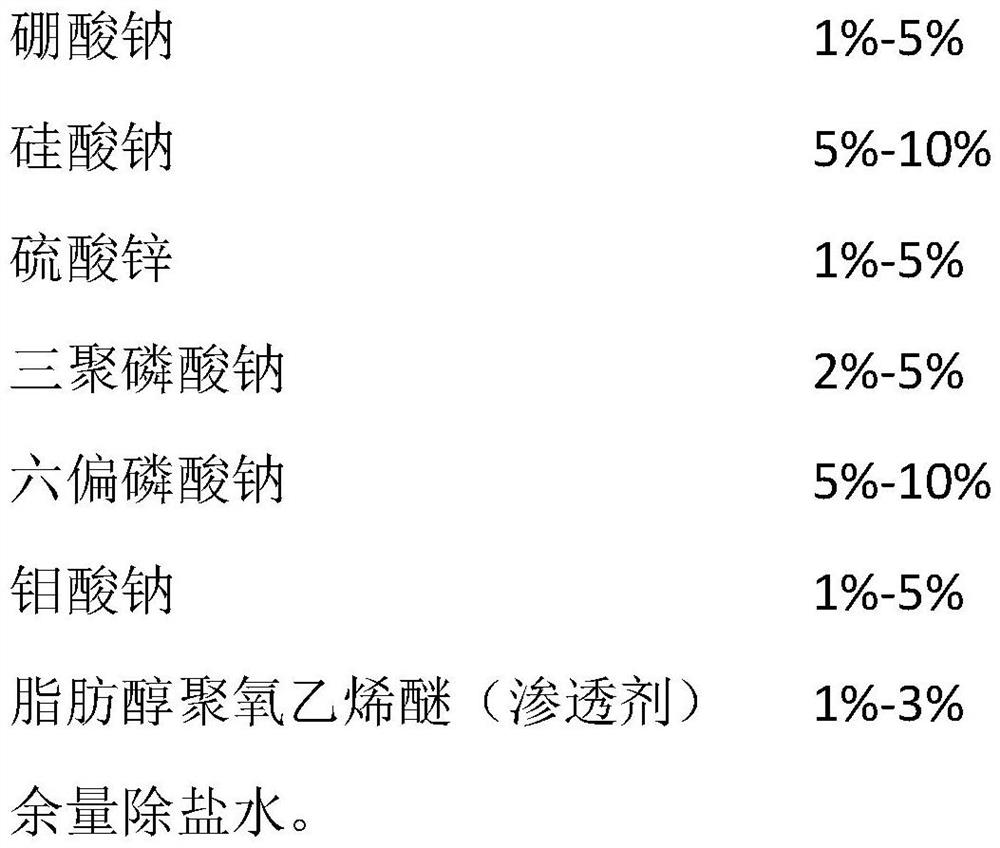

Method used

Image

Examples

Embodiment 1

[0026] (1) Before adding corrosion inhibitor, the corrosion rate of carbon steel and pure aluminum in the circulating water of SCAL intercooling system:

[0027] The corrosion coupon test was carried out in the SCAL intercooling system circulating water (demineralized water) without adding corrosion inhibitors. The test lasted for 72 hours. The weight loss of carbon steel and pure aluminum was calculated according to the method described in GB / T16545-2015, and the weight loss was calculated by weight loss. The corrosion rate of carbon steel and pure aluminum calculated by the method is: the corrosion rate of carbon steel is 0.0393mm / a, and the corrosion rate of pure aluminum is 0.1662mm / a.

[0028] (2) After adding corrosion inhibitor of the present invention, carbon steel and pure aluminum corrosion rate in SCAL type intercooling system circulating water:

[0029] For the circulating water system of the SCAL intercooling system, a corrosion inhibitor suitable for the system i...

Embodiment 2

[0033] (1) Before adding corrosion inhibitor, the corrosion rate of carbon steel and pure aluminum in the circulating water of SCAL intercooling system:

[0034] Add 500μg / LSO to SCAL intercooling system circulating water (demineralized water) without corrosion inhibitor 4 2- After 72 hours of the experiment, the weight loss of carbon steel and pure aluminum was calculated according to the method described in GB / T16545-2015, and the corrosion rates of carbon steel and pure aluminum were calculated by the weight loss method: the corrosion rate of carbon steel was 1.0730 mm / a, the corrosion rate of pure aluminum is 0.0790mm / a.

[0035] (2) After adding corrosion inhibitor of the present invention, carbon steel and pure aluminum corrosion rate in SCAL type intercooling system circulating water:

[0036] For the circulating water system of the SCAL intercooling system, add a mass concentration of 500μg / LSO to the circulating water (de-salted water) 4 2- ) to add a corrosion in...

Embodiment 3

[0041] (1) Before adding corrosion inhibitor, the corrosion rate of carbon steel and pure aluminum in the circulating water of SCAL intercooling system:

[0042] Add 500μg / LCl to SCAL intercooling system circulating water (demineralized water) without corrosion inhibitor - After 72 hours of the experiment, the weight loss of carbon steel and pure aluminum was calculated according to the method described in GB / T16545-2015, and the corrosion rates of carbon steel and pure aluminum were calculated by the weight loss method: the corrosion rate of carbon steel was 0.2270 mm / a, pure aluminum corrosion rate 0.1400mm / a.

[0043] (2) After adding corrosion inhibitor of the present invention, carbon steel and pure aluminum corrosion rate in SCAL type intercooling system circulating water:

[0044] For the circulating water system of the SCAL intercooling system, add a mass concentration of 500μg / LCl to the circulating water (de-salted water) - ) to add a corrosion inhibitor suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com