Gas pipe-line composite reinforcement construction and construction method thereof

A technology for gas pipelines and reinforcing structures, applied in the direction of pipe components, adhesive types, pipes/pipe joints/fittings, etc., can solve hidden dangers and safety problems of open flames, and achieve long service life, slow down corrosion rate, and improve efficiency. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

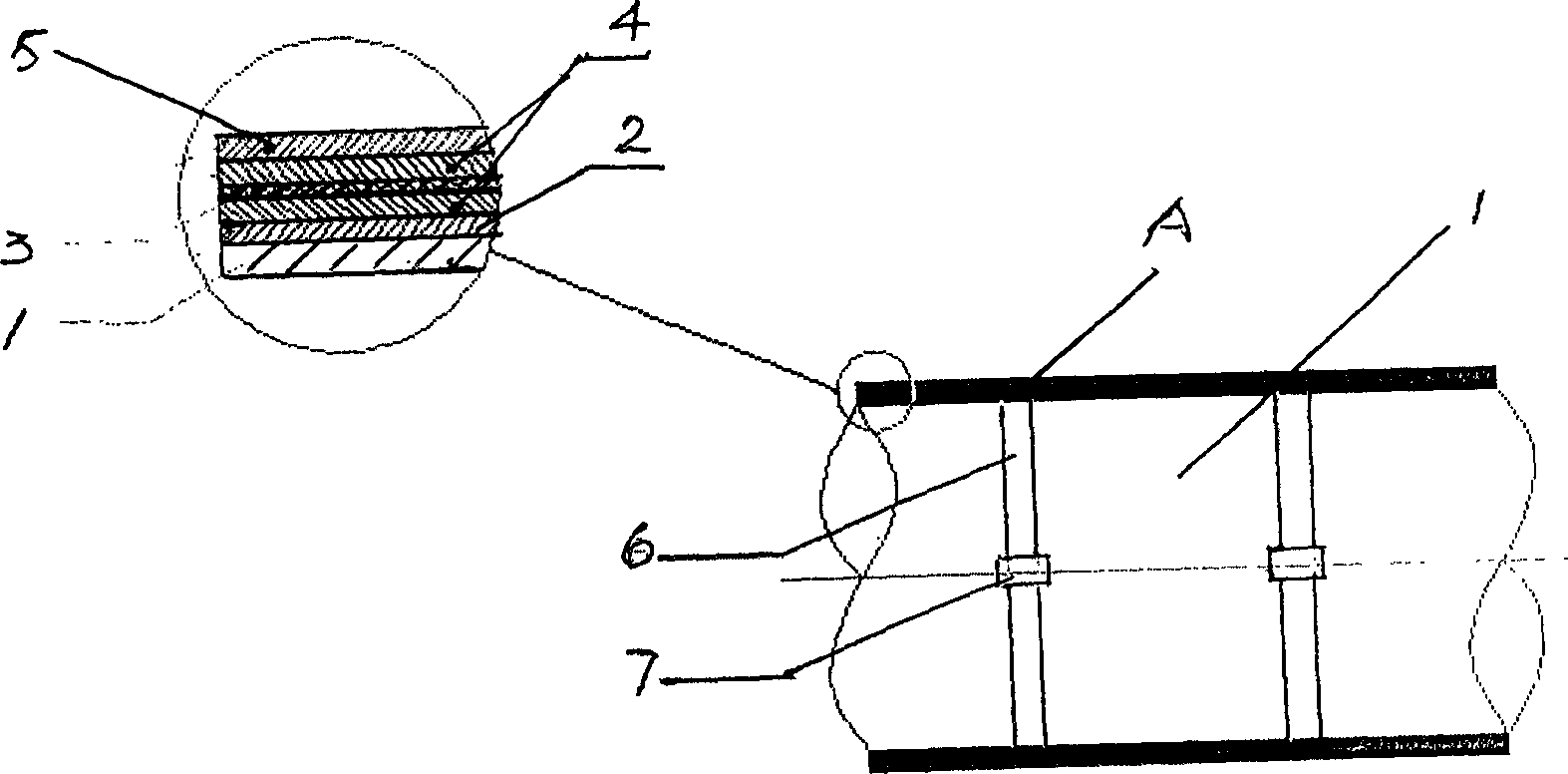

[0029] Embodiment 1: Straight pipe section reinforcement structure (see figure 1 )

[0030] When repairing the straight pipe section of the gas pipeline, the main reinforcing piece A is used in conjunction with the reinforcing keel belt 6. The main reinforcing piece A is coated on the outside of the gas pipeline to be repaired, and is composed of a protective layer 5 , a working layer 4 , a reinforcing layer 3 , and a primer layer 2 . The reinforcing keel belt is composed of a corrosion-resistant stainless steel belt 6a and a special locking buckle 6b, which is directly tightened on the pipeline body 1, and together with the main reinforcing piece A, reinforces the mechanical structure of the original pipeline. The outermost layer of the main reinforcement A is the protective layer 5, which is made of a composite material that is resistant to atmospheric aging, has excellent water resistance, and can reduce the degradation effect of ultraviolet rays on adhesives; the middle i...

Embodiment 2

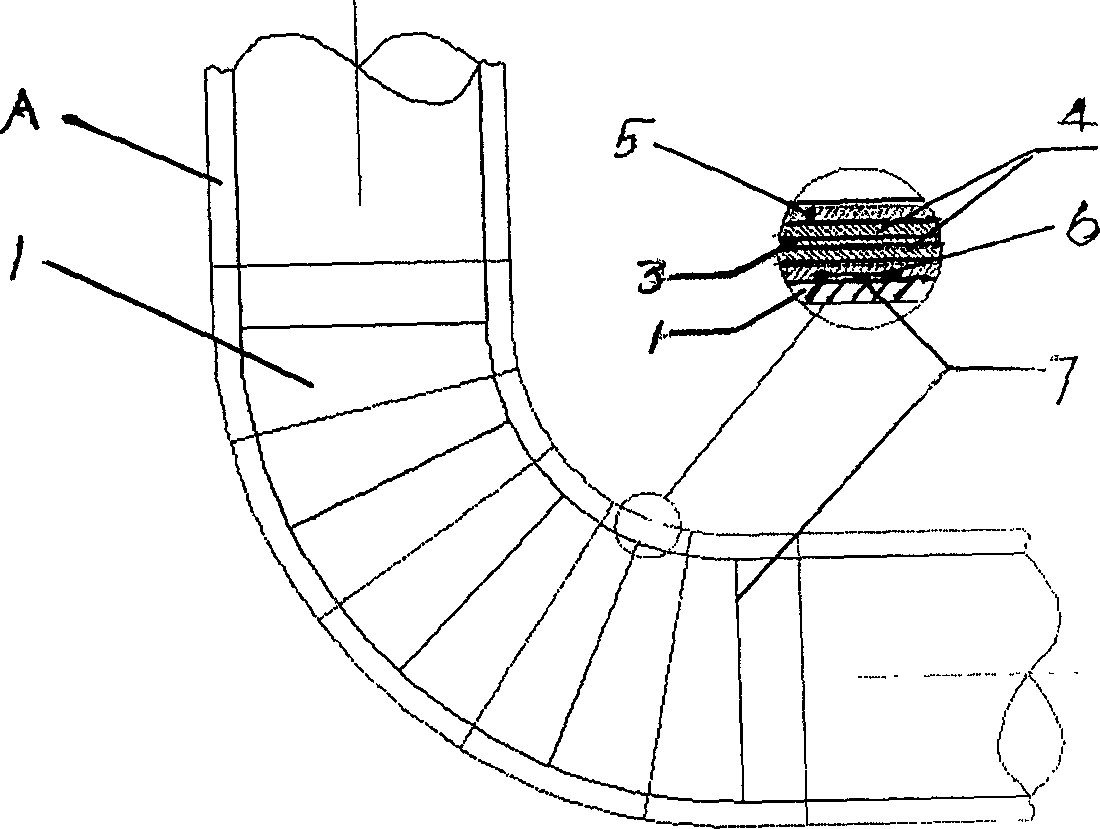

[0032] Embodiment 2: bend section reinforcement structure (see figure 2 ).

[0033] For the repair of the bent pipe section, the 8 welding seams of the bent pipe shall be specially treated first, and then the main reinforcement A shall be used to repair the bent pipe section. That is, at the welding seam 8 of the curved pipe body, an inner reinforcement layer 9 made of glass fiber and structural adhesive is added, and the outermost protective layer 5 is spliced by prefabricated parts cut out according to the shape of the pipe. to ensure effective protection of the working layer 4.

Embodiment 3

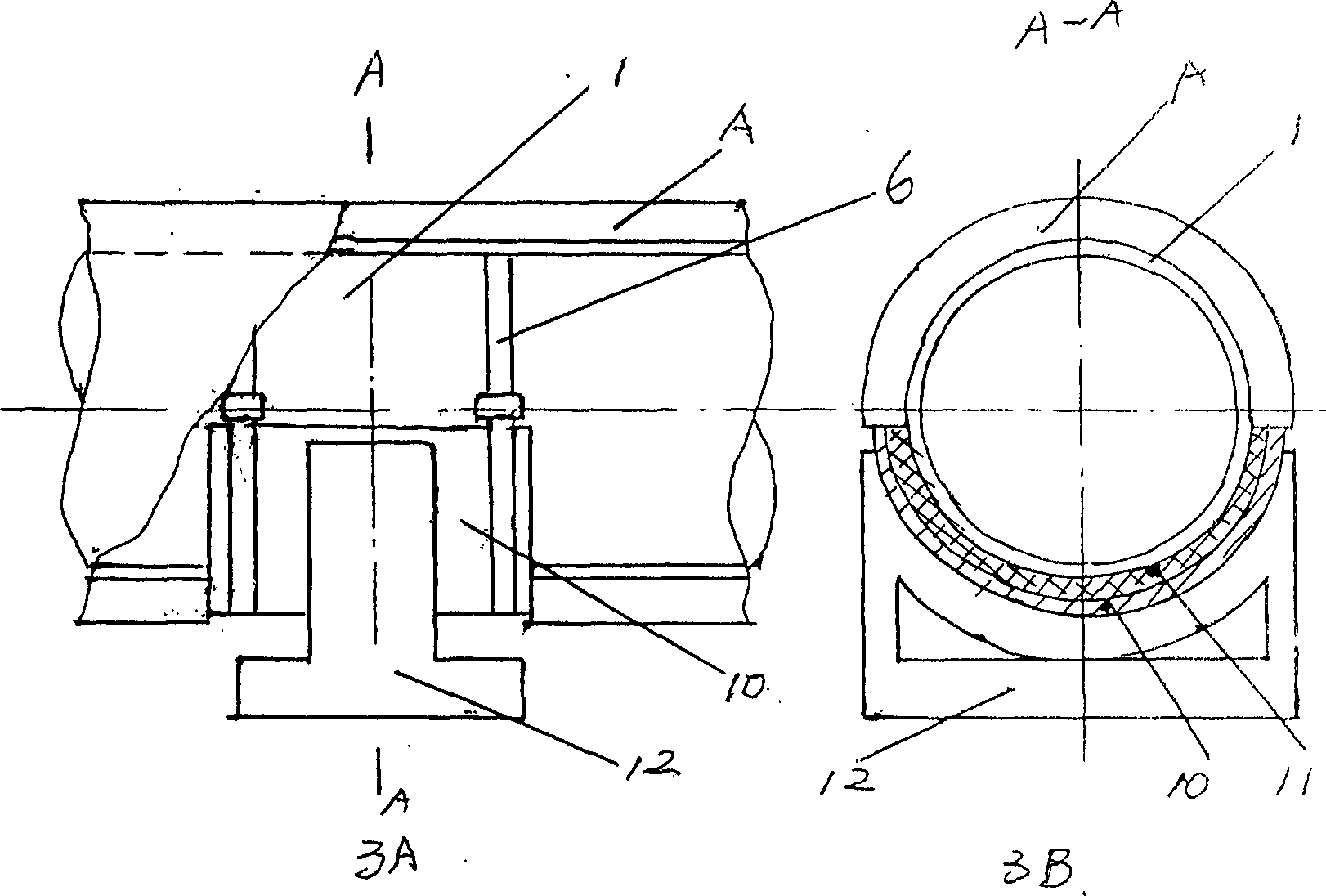

[0034] Embodiment 3: Reinforcing structure of the supporting part of the pipe bracket (see image 3 )

[0035] The overhead pipeline is supported by brackets 12 at intervals. Due to thermal expansion and contraction, the pipeline 1 will slip at the bracket support, so the reinforcements at the bracket support have special requirements for wear resistance. When repairing this part, the main reinforcing piece A is used in conjunction with the special reinforcing piece. The main reinforcement A used is similar to the main reinforcement of the straight pipe section, and the special reinforcement is composed of wear-resistant steel plate 10 and composite glue layer 11 .

[0036] During repairing, wear-resistant steel plate 10 is pasted on the gas pipeline body 1 above support bracket 12 with composite adhesive layer 11 earlier, then is fastened with corrosion-resistant stainless steel reinforcement keel belt 6 again. The composite adhesive layer 11 plays the role of sealing and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com