Dispersing agent

A technology of dispersant and general formula, applied in the field of dispersants for printing and dyeing, can solve the problems of reduced fiber adhesion, unchanged molecular structure, reduced desizing rate, etc., and achieves good scale inhibition and dispersion performance, good coordination and synergy effect, good biodegradability

Inactive Publication Date: 2017-11-03

王蒙

View PDF8 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because during alkali desizing, although the alkali can swell the slurry to a certain extent, transforming it from a gel state to a sol state, reducing the adhesion to the fiber, but the molecular structure of the slurry has not changed, and the degree of polymerization If it is not removed immediately, the pulp will be re-contaminated, reducing the desizing rate and causing pulp spots

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 3

[0025] Prepare 60 parts by mass of (103), 40 parts of aminotrimethylene phosphonic acid, and 35 parts of sodium polyacrylate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

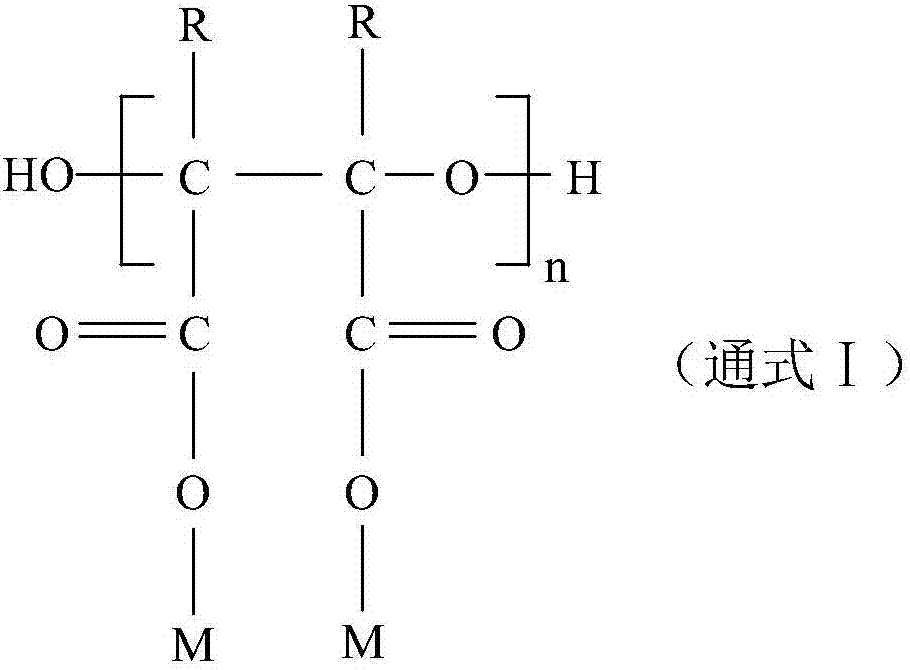

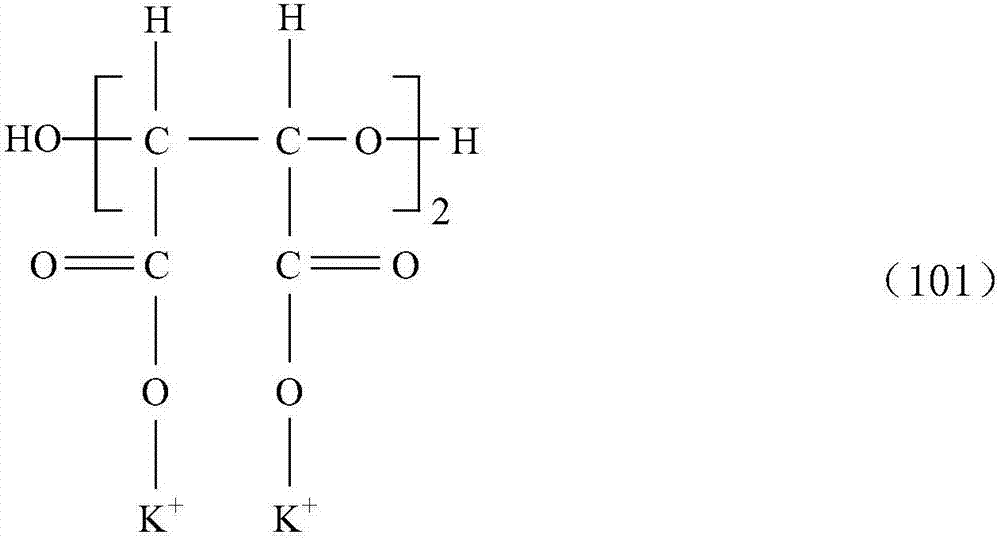

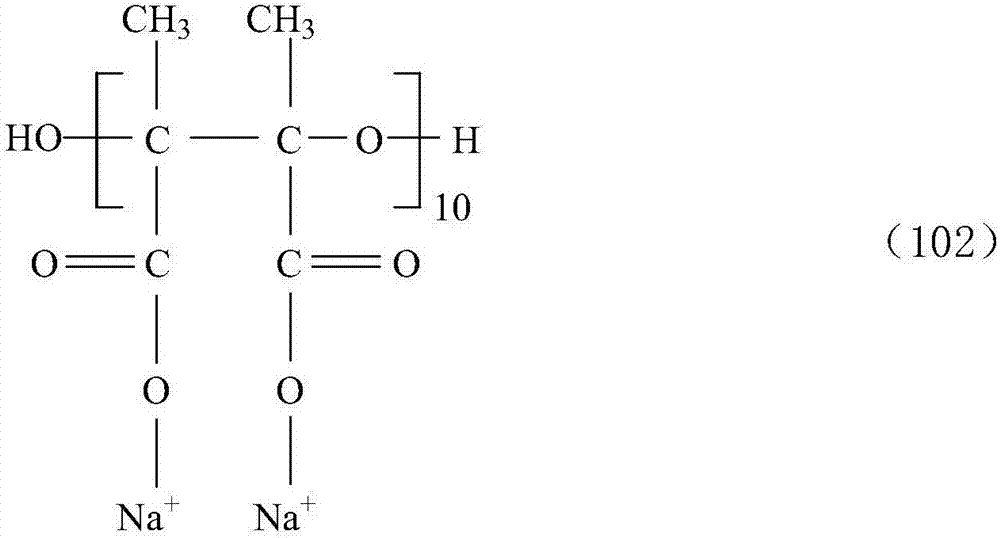

The invention relates to a dispersing agent, in particular to a dispersing agent for printing and dyeing. The dispersing agent comprises the following components in parts by mass: 50 to 70 parts of a dispersing agent as shown in a general formula I, 30 to 40 parts of organic phophonic acid and 25 to 35 parts of polyacrylic acid or salt thereof. The dispersing agent as shown in the general formula I has high scale-inhibiting and dispersing properties on calcium carbonate, calcium sulfate, barium sulfate, calcium fluoride and silicon scale, also has an excellent corrosion-inhibiting effect and is a polynary scaling inhibitor. The polyacrylic acid or the salt thereof can disperse microcrystals or silt of the salt such as calcium carbonate and calcium sulfate into water to avoid precipitation so as to fulfill the scale-inhibiting purpose. The dispersing agent as shown in the general formula I and the organic phophonic acid mutually cooperate to have good synergistic effect; furthermore, the dispersing agent has high biodegradability, is widely applied and has high solubility with other aids for printing and dyeing.

Description

technical field [0001] The invention relates to a dispersant, in particular to a dispersant for printing and dyeing. Background technique [0002] The dispersant is a compound with a ring structure formed by the combination of a central ion and a multi-dentate ligand. It has excellent dispersion, suspension and good ability to complex metal ions; it can prevent equipment and fabrics from being stained and produce relatively Strong anti-scaling and anti-scaling ability; anti-alkali, acid, oxidant, reducing agent; good compatibility with general additives. [0003] The wool effect of the fabric can be improved after adding the dispersant in the textile treatment process. Because during alkali desizing, although the alkali can swell the slurry to a certain extent, transforming it from a gel state to a sol state, reducing the adhesion to the fiber, but the molecular structure of the slurry has not changed, and the degree of polymerization If it is not removed immediately, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D06P1/653D06P1/667D06P1/52

CPCD06P1/6533D06P1/5257D06P1/667

Inventor 王蒙

Owner 王蒙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com