Iron-based nanocrystalline alloy and preparation method thereof

A technology of iron-based nanocrystals and alloys, applied in the field of iron-based alloy materials, can solve the problems of high material cost, saturation magnetic induction intensity of nanocrystalline strips, insufficient anti-saturation ability of output characteristics, and difficulty in meeting high-end requirements due to the miniaturization trend of equipment and devices And other problems, to achieve the effect of improving the magnetic permeability, inhibiting the crystallization phenomenon, and improving the ability of amorphous formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Specifically, the present application also provides a method for preparing the above-mentioned iron-based nanocrystalline alloy, comprising the following steps:

[0050] According to the formula Fe a (BSiPC) b (CuHf) c The atomic percentage batching of the iron-based nanocrystalline alloy, smelting the raw materials after batching, spraying the smelted melt into an alloy strip, and heat-treating the alloy strip to obtain an iron-based nanocrystalline alloy;

[0051] The heat treatment process is followed by the first heat treatment stage, the second heat treatment stage, cooling and cooling, specifically:

[0052] The first heat treatment stage is specifically: heating the alloy raw strip to the first target temperature T1 at a first heating rate, and keeping it warm for t1min;

[0053] The second heat treatment stage is specifically: heating the raw alloy strip after the first heat treatment stage to the second target temperature T2 at a second heating rate, and kee...

Embodiment 1

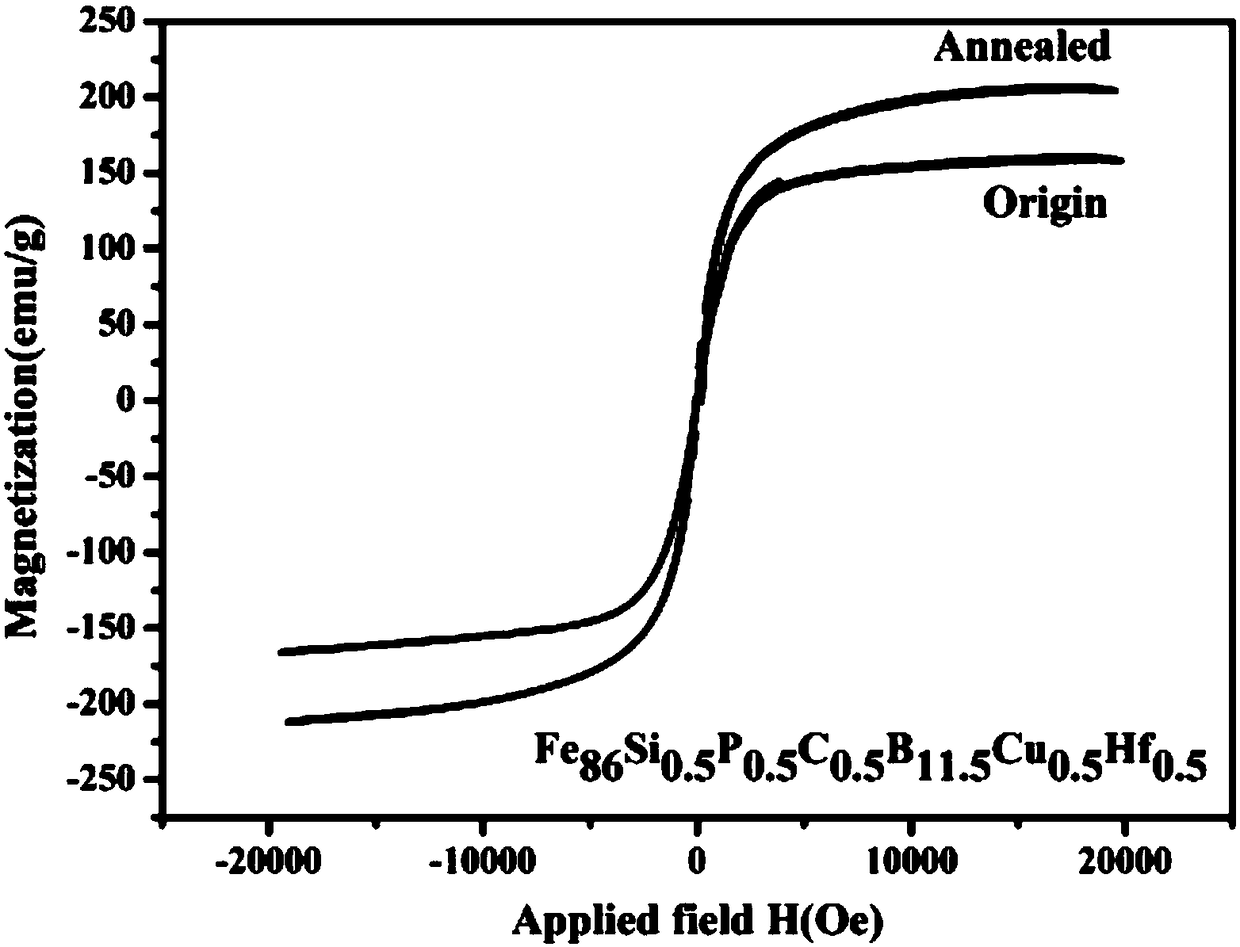

[0079] Ingredients are prepared according to the alloy composition of Fe86Si0.5P0.5C0.5B11.5Cu0.5Hf0.5; metal raw materials are smelted in a vacuum electric arc furnace to obtain molten metal;

[0080] The above molten metal is sprayed into an alloy strip with a width of 2 to 3 mm and a thickness of 24 to 28 microns by spraying the belt machine;

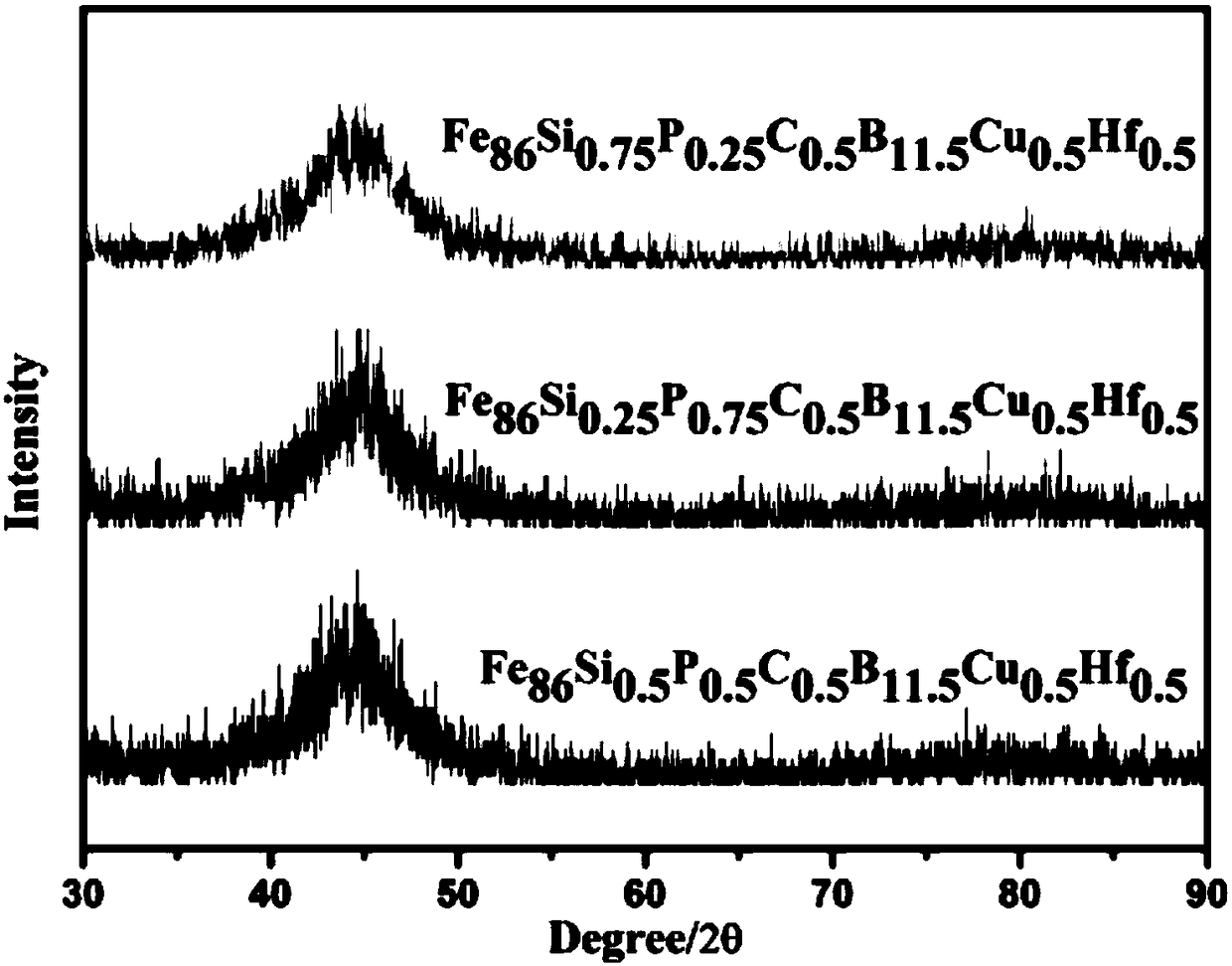

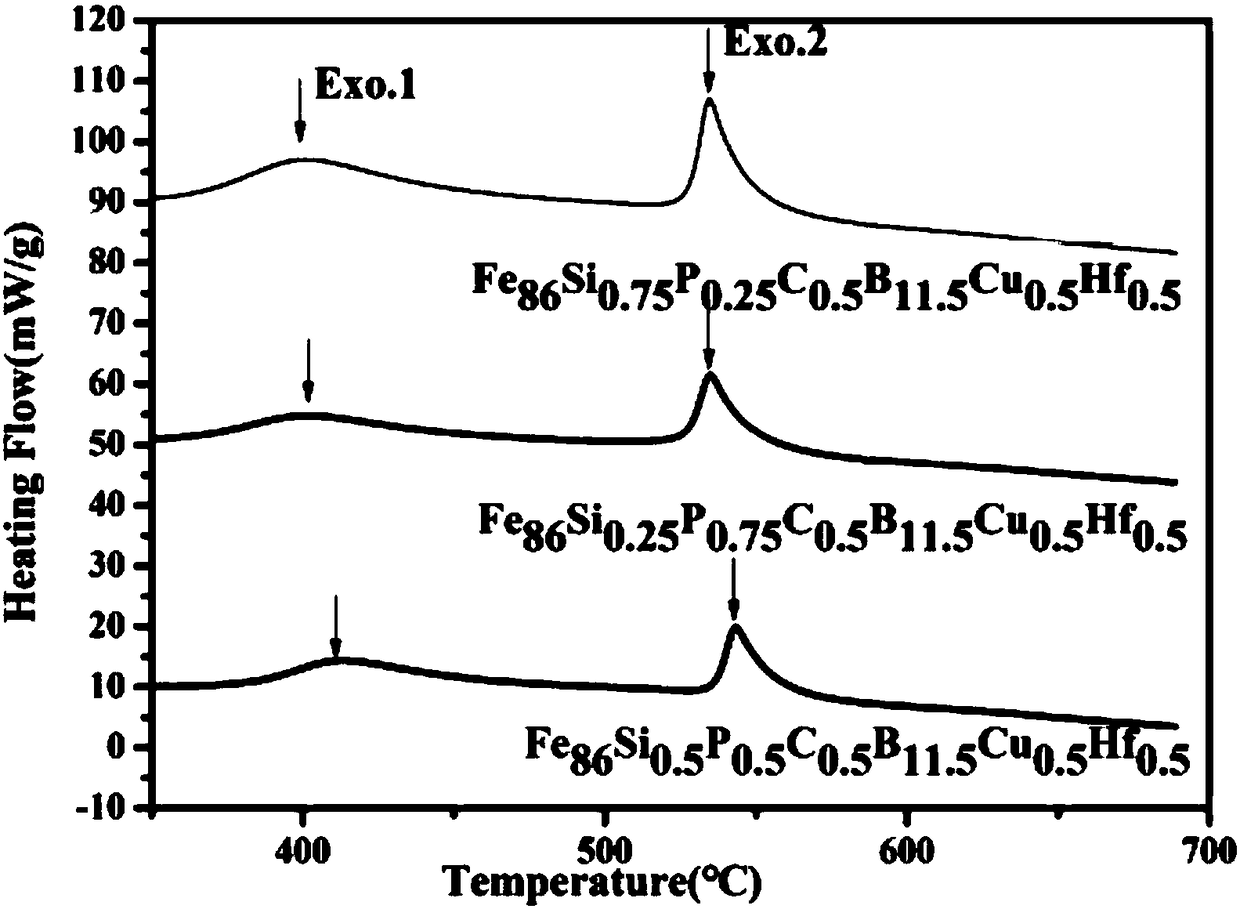

[0081] X-ray diffraction was used to test the amorphous phase structure of the original alloy strip, and DSC was used to test the phase transition exothermic peak of the alloy raw material. Under the condition of a heating rate of 20°C / min, the initial temperature and The peak temperatures are 390°C and 415°C respectively, and the peak temperature of the second phase transition peak is 535°C; figure 1 and figure 2 as shown, figure 1 It is the XRD photo of the original alloy strip, figure 2 It is the DSC exothermic curve figure of the original alloy strip;

[0082] The temperature of the second phase transition peak is selected ...

Embodiment 2

[0093] The preparation method is the same as in Example 1, except that the alloy composition is Fe86Si0.25P0.75C0.5B11.5Cu0.5Hf0.5; the initial temperature and peak temperature of the first exothermic peak of phase transition are determined to be 380°C and 405°C respectively, and the first The peak-to-peak temperature of the two-phase transformation is 525°C. The second phase transformation peak temperature is selected to be 25°C lower than the heat treatment temperature holding point, and the original alloy strip is effectively heat-treated by rapid oscillation heat treatment. The specific process is as follows:

[0094] Step.1 The first target temperature is 360°C, the first heating rate is 2°C / min, and the first holding time is 60min;

[0095] Step.2 The second target temperature is 405°C, the second heating rate is 1°C / min, and the second holding time is 150min;

[0096] Step.3 The third target temperature is 500°C, the second heating rate is 1°C / min, and the second holdin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com