Anti-static polyurethane pouring sealant and using method thereof

A polyurethane and antistatic technology, which is applied in the field of potting glue, can solve the problems of poor antistatic timeliness and damage performance of surfactants, and achieve the effects of inhibiting static accumulation, accelerating dissipation, and good adsorption

Active Publication Date: 2017-12-15

驻马店进化伙伴机器人有限公司

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the migration of surfactants is in all directions, and the migrating surfactants will damage the performance of electronic or LED components after reaching the surface, and the antistatic timeliness of surfactants is poor, generally no more than six months

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

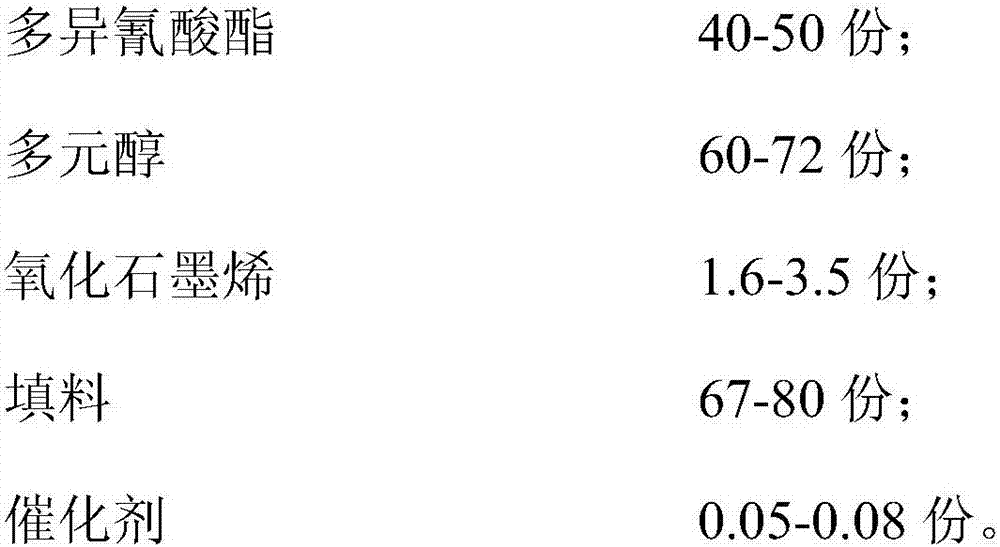

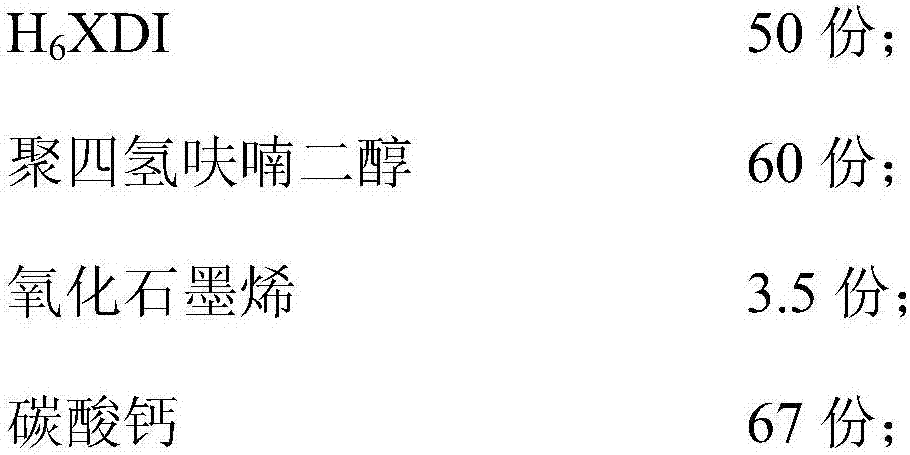

[0051] A kind of antistatic polyurethane encapsulant, comprises the component of following parts by weight:

[0052]

Embodiment 2

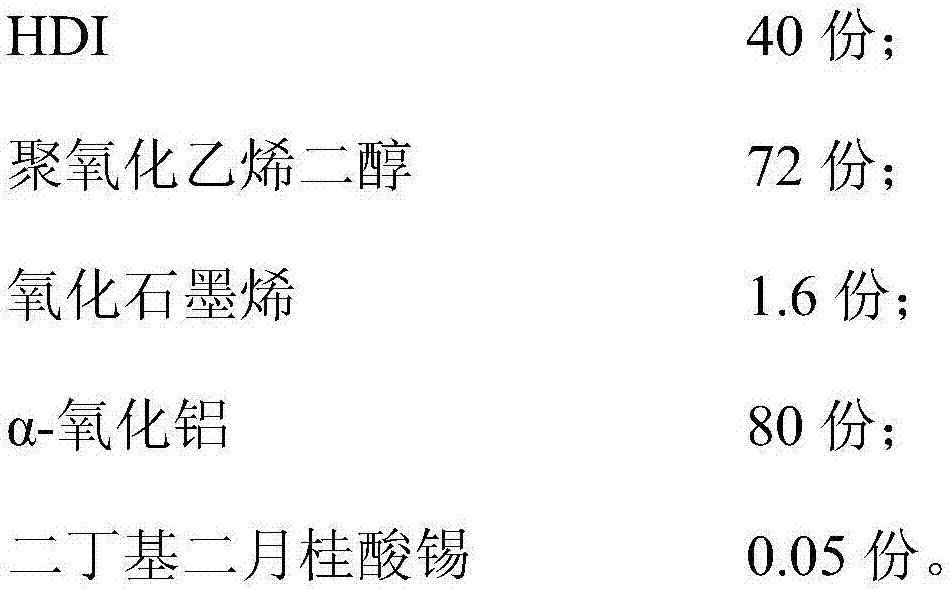

[0054] A kind of antistatic polyurethane encapsulant, comprises the component of following parts by weight:

[0055]

[0056]

Embodiment 3

[0058] A kind of antistatic polyurethane encapsulant, comprises the component of following parts by weight:

[0059]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an anti-static polyurethane pouring sealant and a using method thereof. The anti-static polyurethane pouring sealant comprises the following components in parts by weight: 40 to 50 parts of polyisocyanates, 60 to 72 parts of polyhydric alcohols, 2 to 2.4 parts of oxidized graphene, 67 to 80 parts of a filler and 0.05 to 0.08 part of a catalyst. The using method comprises the following steps: after all components of the anti-static polyurethane pouring sealant are mixed, pouring an object to be poured, and then curing the object to be poured at the temperature of 20 to 30 DEG C for 24 to 48 h to form a sealant block. The anti-static polyurethane pouring sealant provided by the invention has good mechanical performance after being cured, has relatively high insulation performance and anti-static performance, and is particularly applicable for pouring of electrical apparatus elements.

Description

technical field [0001] The invention belongs to the technical field of potting glue, and in particular relates to an antistatic polyurethane potting glue and a using method thereof. Background technique [0002] With the widespread popularization of electronic products, LED lighting and outdoor light art works, the components are becoming more and more small in size and highly integrated, resulting in smaller and smaller wire spacing, thinner and thinner insulating films, and improved electrical breakdown resistance. Also getting worse. However, the electrostatic voltage accumulated by electronic products in the process of production, storage and transportation far exceeds its breakdown voltage threshold (for example, the withstand voltage threshold of LED blue light wafers is only more than 1000 volts, and it is easy to be broken down by static electricity). It may cause breakdown or failure of the device, reduce its reliability and bring safety hazards. [0003] Potting ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J175/06C09J175/08C09J175/04C09J11/04C09J11/08C09J11/06C08G18/48C08G18/42C08G18/64

CPCC08G18/4277C08G18/4825C08G18/4833C08G18/4854C08G18/64C08K2003/026C08K2003/2227C08K2003/2296C08K2003/265C08K2003/282C08K2003/323C08K2003/385C08L2201/04C08L2203/206C09J11/04C09J11/06C09J11/08C09J175/04C09J175/06C09J175/08C08L71/02C08K13/04C08K3/22C08K3/04C08K3/346C08K3/32C08K7/26C08K3/28C08K3/36C08K3/38C08K3/02C08K3/34

Inventor 张健威詹宏朝

Owner 驻马店进化伙伴机器人有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com