Triazole ionic liquid-doped perovskite solar cell and preparation method thereof

A technology of solar cells and ionic liquids, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., to achieve the effects of delaying crystallization rate, increasing short-circuit current density, and excellent hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Treatment of ITO glass: first, clean the surface of ITO glass with a size of 15mm×15mm and an impedance of 10Ω / sq with decontamination powder, then ultrasonically treat it in deionized water, absolute ethanol and acetone for 15 minutes, and then Blow dry with nitrogen, and finally UV-treat the ITO glass for 15 minutes;

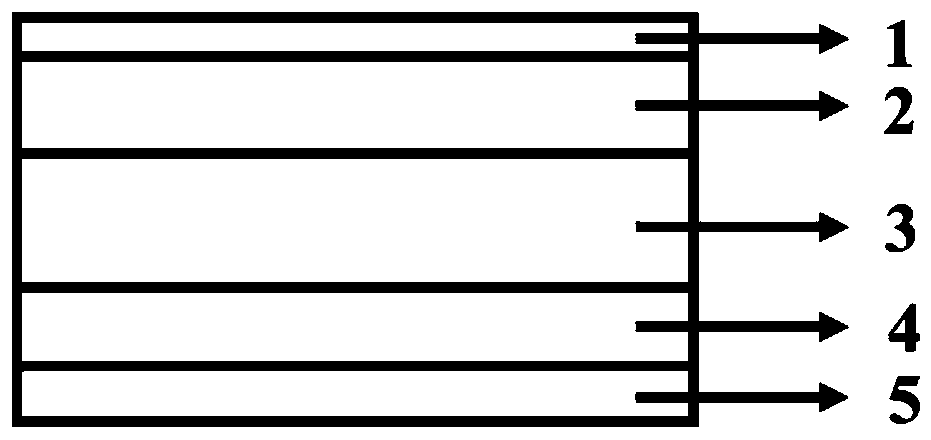

[0039] 2) Spin coating of the electron transport layer: firstly, the prepared TiO 2 The solution was spin-coated on the ITO glass treated in step 1) at a rate of 3000 rpm for 60 seconds, then annealed in air at 150°C for 10 minutes, and slowly cooled to room temperature to obtain dense TiO 2 Electron transport layer;

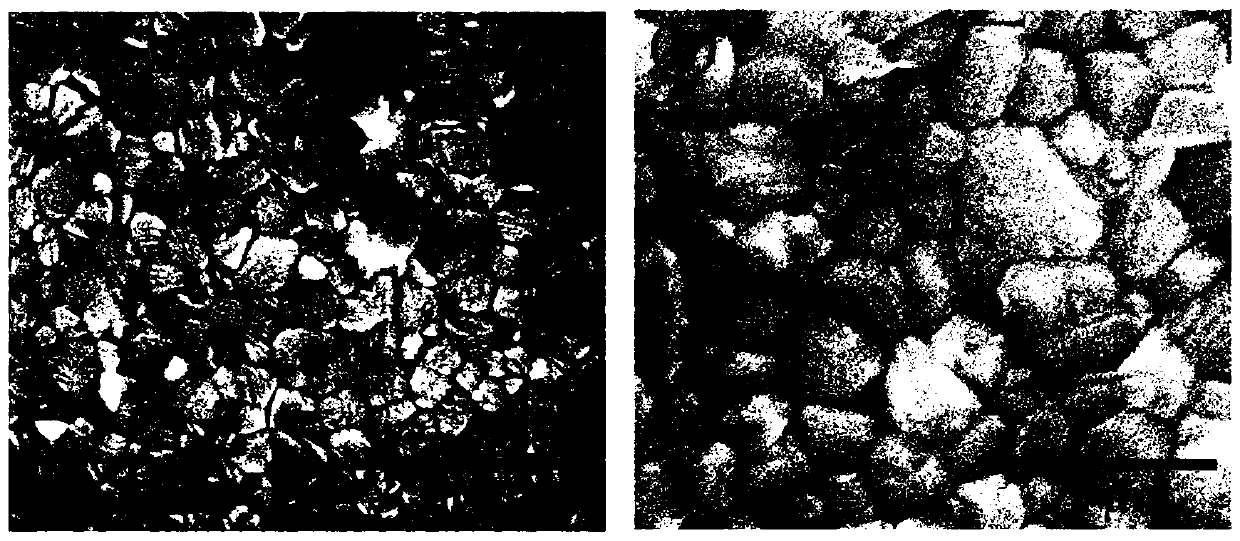

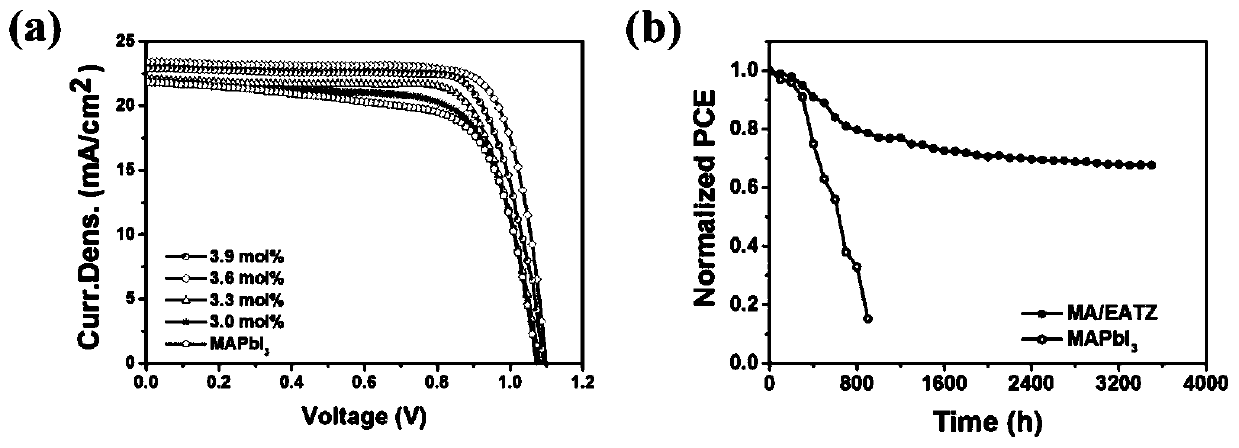

[0040] 3) "MA / EATZ" method for spin-coating perovskite light-absorbing layer: put the above-mentioned ITO glass treated in step 2) into a glove box. Take equimolar ratio of CH 3 NH 3 I and PbI 2 Add it into a mixed solvent of γ-butyrolactone and DMSO with a volume ratio of 7:3 and stir fully to obtain a pure perovskite precursor s...

Embodiment 2

[0045] 1) Treatment of ITO glass: first, clean the surface of ITO glass with a size of 15mm×15mm and an impedance of 10Ω / sq with decontamination powder, then ultrasonically treat it in deionized water, absolute ethanol and acetone for 15 minutes, and then Blow dry with nitrogen, and finally UV-treat the ITO glass for 15 minutes;

[0046] 2) Spin coating of the electron transport layer: firstly, the prepared TiO 2 The solution was spin-coated on the ITO glass treated in step 1) at a rate of 3000 rpm for 60 seconds, then annealed in air at 150°C for 10 minutes, and slowly cooled to room temperature to obtain dense TiO 2 Electron transport layer;

[0047] 3) "MA / EATZ" method for spin-coating perovskite light-absorbing layer: put the above-mentioned ITO glass treated in step 2) into a glove box. Take equimolar ratio of CH 3 NH 3 I and PbI 2 Add it into a mixed solvent of γ-butyrolactone and DMSO with a volume ratio of 7:3 and stir fully to obtain a pure perovskite precursor s...

Embodiment 3

[0052] 1) Treatment of ITO glass: first, clean the surface of ITO glass with a size of 15mm×15mm and an impedance of 10Ω / sq with decontamination powder, then ultrasonically treat it in deionized water, absolute ethanol and acetone for 15 minutes, and then Blow dry with nitrogen, and finally UV-treat the ITO glass for 15 minutes;

[0053] 2) Spin coating of the electron transport layer: firstly, the prepared TiO 2 The solution was spin-coated on the ITO glass treated in step 1) at a rate of 3000 rpm for 60 seconds, then annealed in air at 150°C for 10 minutes, and slowly cooled to room temperature to obtain dense TiO 2 Electron transport layer;

[0054] 3) "MA / EATZ" method for spin-coating perovskite light-absorbing layer: put the above-mentioned ITO glass treated in step 2) into a glove box. Take equimolar ratio of CH 3 NH 3 I and PbI 2 Add it into a mixed solvent of γ-butyrolactone and DMSO with a volume ratio of 7:3 and stir fully to obtain a pure perovskite precursor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com