Method for preparing porous granular composite material from red mud and fly ash as raw materials

A composite material, fly ash technology, applied in the field of preparation of porous granular composite materials, to achieve the effect of environmental friendliness, uniform particle size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

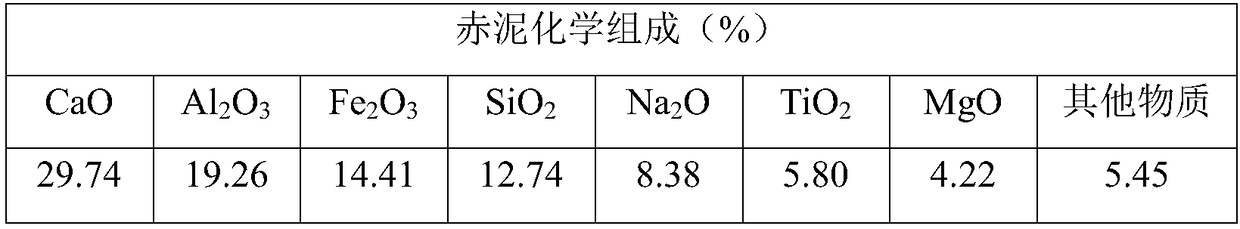

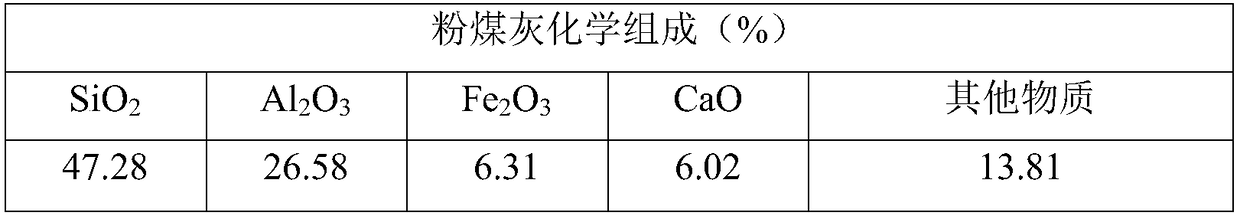

[0033] After drying and crushing the red mud from the aluminum plant, pass it through a 100-mesh sieve to make the particle size of the raw material powder relatively uniform and easy to mix fully; according to the sintering method, the mass ratio of red mud, fly ash and cement is 85:10:5 to take a certain quality The raw materials are mixed evenly, and the raw meal granules with a diameter of 5-8mm are made into uniform raw meal particles through a granulator; the raw meal is passed into a microwave activation reactor for curing and activation for 15 minutes, and the power per unit mass is 7.3667w / g. After cooling at room temperature, a granular porous adsorption material with a certain strength can be obtained, and its specific surface area is 17.8372m 2 / g.

Embodiment 2

[0035] After drying and crushing the red mud from the aluminum plant, pass through a 100-mesh sieve to make the particle size of the raw material powder relatively uniform and easy to mix fully; according to the sintering method, the mass ratio of red mud, fly ash and cement is 80:15:5 to take a certain quality The raw materials are mixed evenly, and the raw meal granules with a diameter of 5-8mm are made into uniform raw meal particles through a granulator; the raw meal is passed into the microwave activation reactor for 20 minutes of curing and activation, and the unit mass power is 13.8667w / g. After cooling at room temperature, a granular porous adsorption material with a certain strength is obtained, and its specific surface area is 19.4283m 2 / g.

Embodiment 3

[0037] After drying and crushing the red mud from the aluminum plant, pass through a 100-mesh sieve to make the particle size of the raw material powder relatively uniform and easy to mix fully; according to the sintering method, the mass ratio of red mud, fly ash and cement is 75:20:5 to take a certain quality The raw materials are mixed evenly, and the raw meal particles with a diameter of 5-8mm are made into uniform raw meal particles through a granulator; the raw meal is passed into a microwave activation reactor for 30 minutes of curing and activation, and the unit mass power is 19.5w / g. After cooling at room temperature, a granular porous adsorption material with a certain strength can be obtained, and its specific surface area is 23.2719m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com