Pesticide microcapsule employing metal ion chelate of tannin as capsule wall and preparation method of pesticide microcapsule

A metal ion, metal ion solution technology, applied in the field of pesticides, to achieve the effect of safety for producers, help plant growth, and reduce the risk of direct contact with pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

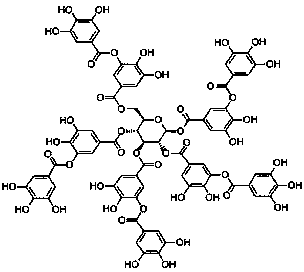

[0030] Dissolve 10.00g of 96wt% chlorpyrifos in 10.00g of xylene to make an oil phase; dissolve 0.85g of alkylphenol ethoxylates, 1.50g of sodium lignosulfonate and 0.20g of gum arabic in 60.00g of deionized Make the water phase in water; add the oil phase to the water phase, emulsify at a high speed of 10,000 rpm for 30 seconds, then transfer the emulsion to a three-necked flask, stir at 200 rpm, and pass in nitrogen, at 40-45 Keep warm at ℃; slowly add 1.00g 5wt% ferric chloride solution dropwise (dropping speed 1-2d / s) at an interval of 5 minutes, then slowly drop (dropping speed 1-2d / s) 1.13g 14wt% ferric chloride solution Nitric acid (the structure diagram of the tannic acid used is shown in figure 1 Shown) solution, and then an interval of 5 minutes is a cycle, a total of 15 cycles; the obtained microcapsule crude product is centrifuged, washed 3 times with deionized water, and vacuum-dried to obtain the tannic acid-iron ion Chlorpyrifos microcapsules as wall material. ...

Embodiment 2

[0032] Dissolve 10.00g of 95% lambda-cyhalothrin in 10.00g of 150# solvent oil to make an oil phase; dissolve 0.65g of alkylphenol polyoxyethylene polyoxypropylene ether, 2.00g of NNO and 0.50g of polyvinyl alcohol Prepare the water phase in 45.00g of deionized water; add the oil phase to the water phase, emulsify at a high speed of 10,000 rpm for 30 seconds, then transfer the emulsion to a three-necked flask, stir at 200 rpm, and inject nitrogen , keep warm at 40-45°C; first slowly add (dropping speed 1-2d / s) 0.66g 5 wt % calcium chloride solution at an interval of 5 minutes, then slowly drop (dropping speed 1-2d / s) 1.00 g 10 wt % tannic acid solution, followed by another 5 minutes interval for one cycle, a total of 14 cycles; the obtained microcapsule crude product was centrifuged, washed 3 times with deionized water, and vacuum-dried to obtain tannin Beta-cyhalothrin microcapsules with acid-calcium ions as the wall material. The particle size of the pesticide microcapsules...

Embodiment 3

[0034] Dissolve 10.00g 95% pendimethalin original drug in 15.00g xylene to make oil phase; dissolve 0.45g castor oil ethylene oxide adduct, 2.40g calcium lignosulfonate and 0.20g gum arabic in 70.00g of deionized water to make the water phase; add the oil phase to the water phase, 10000 rpm high-speed homogeneous emulsification for 30 seconds, then transfer the emulsion to a three-necked flask, stir at 200 rpm, and feed nitrogen, Insulate at 40-45°C; slowly drop (dropping speed 1-2d / s) 1.00g of 4 wt% aluminum chloride solution at an interval of 5 minutes, then slowly drop (dropping speed 1-2d / s) 0.96g 16 wt % tannic acid solution, and another 5 minutes interval, which is a cycle, a total of 15 cycles; the obtained microcapsule crude product is centrifuged, washed 3 times with deionized water, and vacuum-dried to obtain tannic acid - pendimethalin microcapsules with aluminum ions as the wall material. The particle size of the pesticide microcapsules prepared in this example is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com