Lactobacillus sanfranciscensis Ls-1001 bread and preparation method thereof

A technology of Lactobacillus san Francisco and bread, which is applied in the field of food processing, can solve the problems that the fermentation flavor and aroma of bread are not strong enough, the fermentation acidity is not pure and soft enough, and the quality of bread is poor, so as to achieve better sensory quality, uniform internal texture and structure, Delicate and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

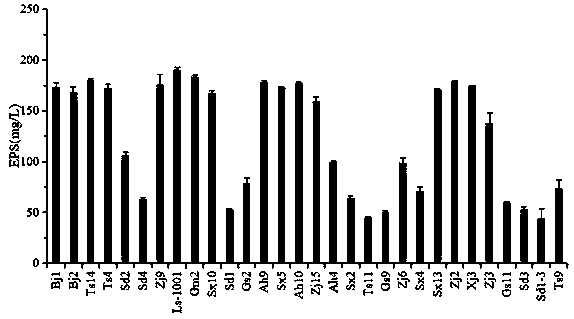

[0047] Example 1 Exopolysaccharide production of different bacterial strains

[0048] figure 1 Shows the difference in the production of exopolysaccharides of different strains, by figure 1 It can be seen that the exopolysaccharide production of Lactobacillus San Francisco Ls-1001 was the highest at 190.32 mg / L.

Embodiment 2

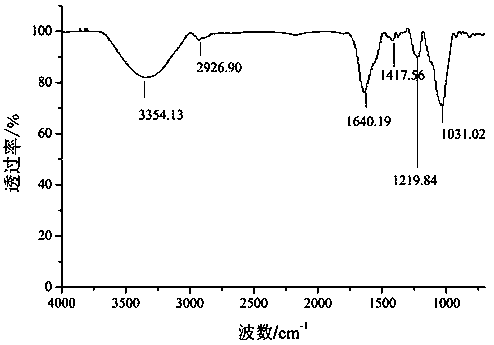

[0049] Example 2 Infrared spectrum analysis of the exopolysaccharide of Lactobacillus San Francisco

[0050] figure 2 Shows the infrared spectrogram of Lactobacillus San Francisco Ls-1001 exopolysaccharide, obtained by figure 2 It can be seen that at a wavelength of 3354.13cm -1 The broad and strong peak at , represents the O-H stretching vibration. at 2926.90 cm -1 The weaker absorption peak at is the absorption peak caused by the C-H saturation stretching vibration. at 1640.19 cm -1 The strong absorption peak at is indicative of the presence of carbonyl asymmetric stretching vibrations. 1417.56 cm -1 and 1219.84 cm -1 The absorption peaks at are the alkyl hydrogen (CH 2 -CH 3 ) stretching vibration and O-H stretching vibration. at 1031.02 cm -1 where is the C-O stretching vibration.

Embodiment 3

[0051] Example 3 San Francisco lactobacillus bread (3.0×10 9 CFU / 200 g flour)

[0052] Ingredients: 200 g high-gluten flour, 2 g Angel high-active dry yeast, 90 g water, 30 g white sugar, 2 g salt, 20 g butter, 60 g eggs, 10 g skimmed milk powder, fermented with Lactobacillus San Francisco Ls-1001 Liquid 5mL, in which the number of colonies is 6.0×10 8 CFU / mL.

[0053] The method for making the fermentation liquid of Lactobacillus San Francisco Ls-1001 into a sludge is as follows: anaerobic culture of Lactobacillus San Francisco Ls-1001 in the mMRS medium with an inoculum of 1% by volume, at a culture temperature of 28-30 °C, and culture The time is 22~24 h, the anaerobic condition is N 2 , CO 2 , O 2 , and its volume percentage is 79:20:1. The cultured Lactobacillus San Francisco Ls-1001 fermentation liquid was centrifuged at 3000-4000 r / min for 4-5 minutes, the supernatant was poured off, and the precipitate was collected to obtain Lactobacillus San Francisco Ls-1001 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com