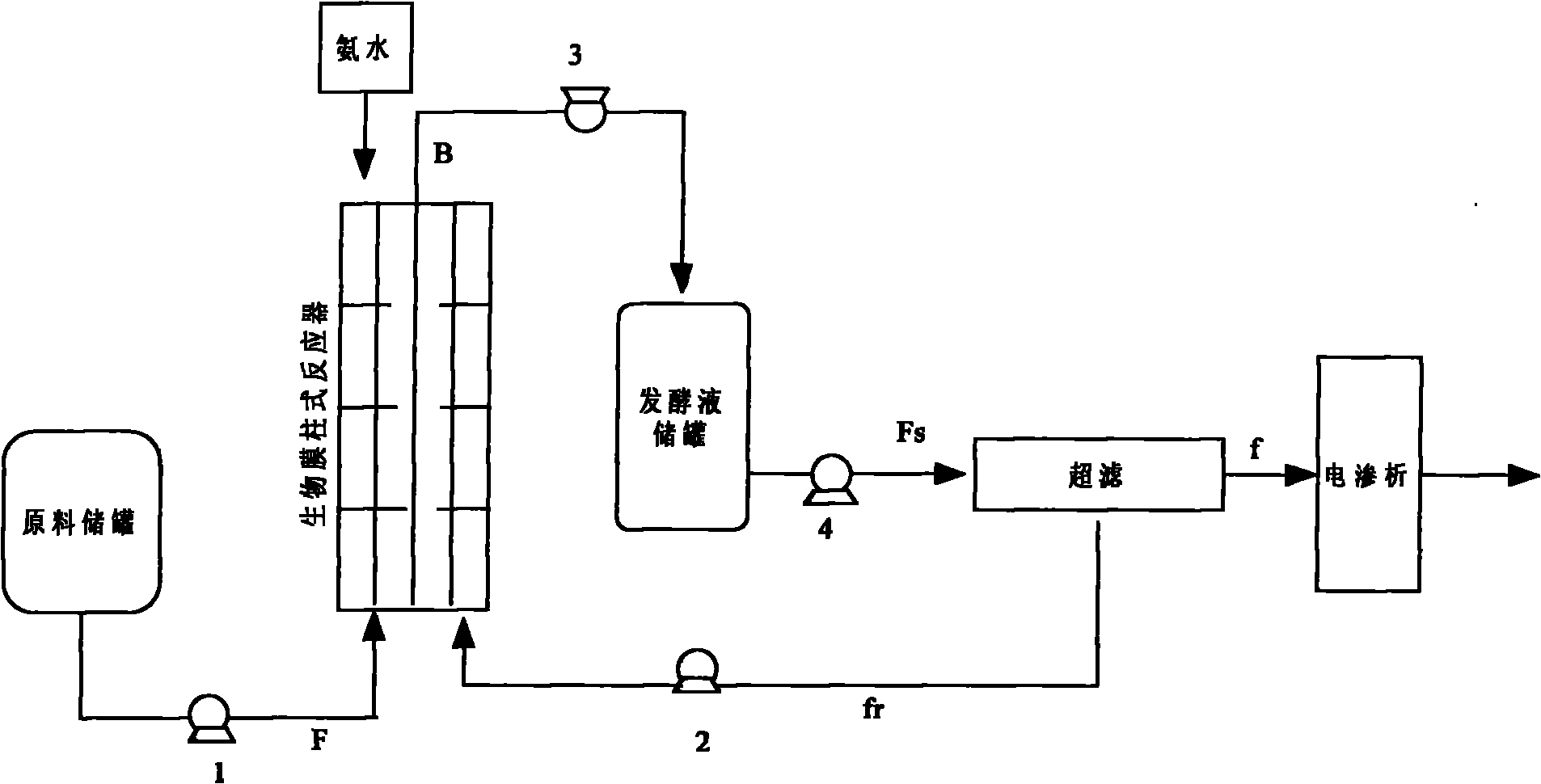

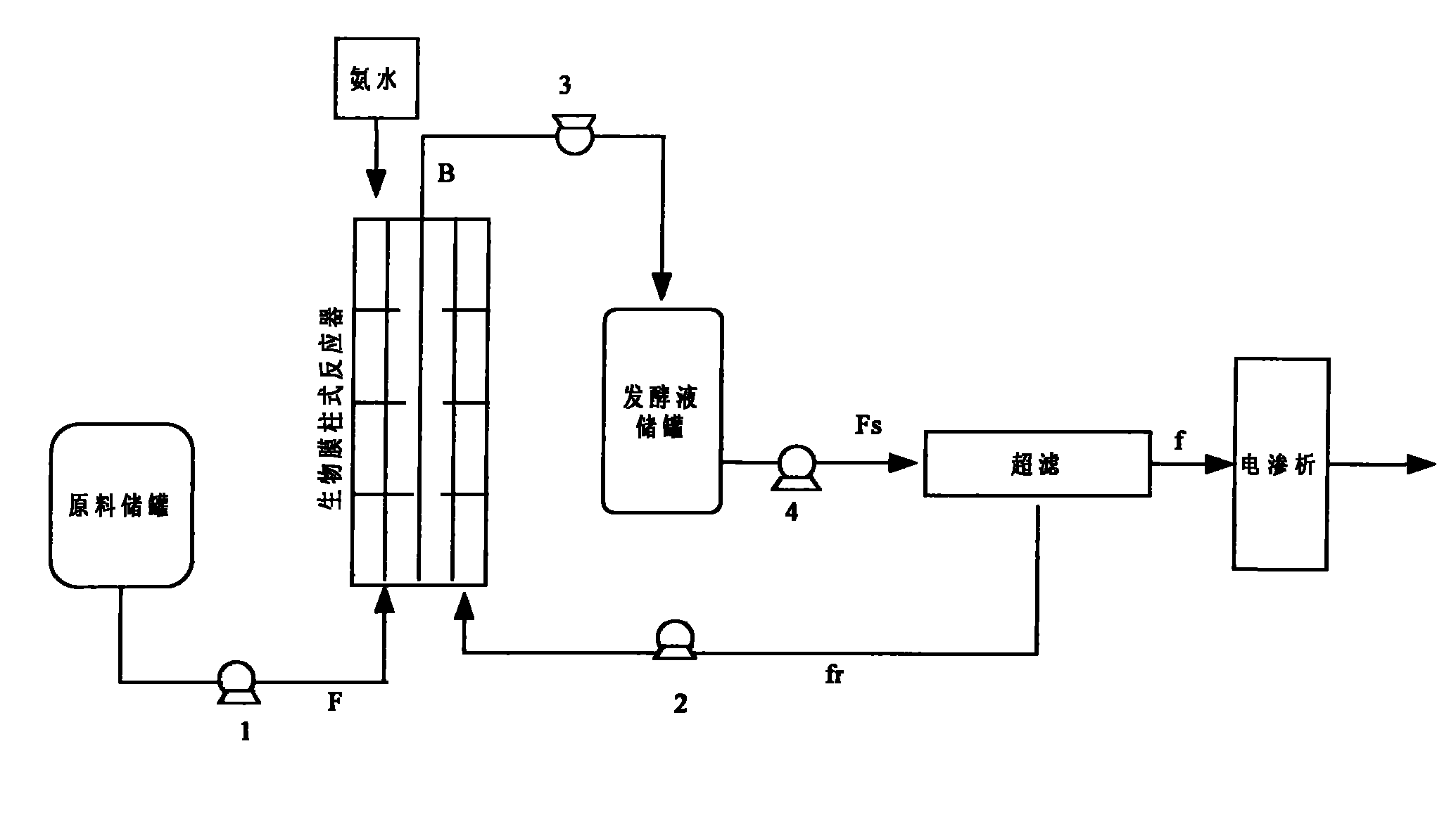

Biomembrane-electrodialysis coupling continuous production technology of L-lactic acid

A technology of biofilm and electrodialysis, which is applied in the direction of microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of low concentration and easy shedding of cells, achieve high sugar yield, and avoid acid and salt wastewater , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] (1) Preparation of saccharification solution: sugar-containing substances are saccharified by low-temperature double-enzyme method, filtered with a plate and frame filter to obtain saccharification solution, and the filter residue can be used as fibrin feed. The concentration of the obtained saccharified liquid is generally 130-200 g / L.

[0027] The sugar-containing substance refers to sugar-containing crops, preferably corn, wheat, sweet potato, potato or molasses; wherein corn, wheat, sweet potato and potato need to be pulverized first, and then amylase is added for hydrolysis.

[0028] (2) Preparation of nutrient substance: the nutrient substance is preferably soybean meal hydrolyzate, bran and corn steep liquor; wherein the preparation method of soybean meal hydrolyzate is: hydrolyze soybean meal with sulfuric acid to obtain soybean meal hydrolyzate as nitrogen source.

[0029] (3) Activate the lactic acid-producing bacteria strain and expand the culture: use an ino...

Embodiment 1

[0040] Embodiment 1. preparation of fermentation broth

[0041] (1) Preparation of saccharification liquid, using double-enzyme hydrolysis method: Weigh 1600g corn flour and add water to 8000mL, adjust the pH value to 6.0-6.4, add a-amylase (600U / g), CaCl 2 (0.01mol / L), maintain at 90°C for about 40 minutes until no starch is detected by iodine solution. Adjust the pH of the liquefied solution to 4.0-4.5, the temperature is 58-62°C, and add glucoamylase (200U / g) to maintain the temperature for 1 hour. Finally, remove the residue with a filter, and use the filtrate to measure the glucose concentration for later use. The glucose concentration of the prepared saccharification solution is 180 g / L.

[0042] (2) Preparation of soybean meal hydrolyzate: weigh a certain amount of soybean meal, add 5 times the amount of water, and mix evenly. Add concentrated sulfuric acid according to 2% of the water amount, mix quickly and evenly, and avoid partial carbonization of the material. A...

Embodiment 2

[0044] Embodiment 2 Lactobacillus activation, expanding culture

[0045] Lactobacillus casei used in the examples was purchased from Beijing Institute of Food Fermentation. The strains stored in the solid medium are picked up with an inoculation loop and inserted into the seed medium, cultured at 42°C for 24 hours, inserted into test tubes and flasks at a ratio of 1:10 for expansion, cultivated at 42°C for 24 hours, and can be seen A large number of bacterial cells are produced, and the bubbles are violent.

[0046] The composition of the seed medium: glucose 4%, soybean peptone 1%, KH 2 PO 4 0.1%, YeastExtract 0.5%, (NH 4 ) 2 SO 4 0.4%, light CaCO 3 1%, pH 6.0-6.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dilution degree | aaaaa | aaaaa |

| Dilution degree | aaaaa | aaaaa |

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com