Preparation method of hydroxyectoine

A technology of hydroxy ectoine and ectoine, which is applied in the field of preparation of hydroxy ectoine, can solve the problems of decreased synthesis of ectoine, complex control process, high production cost, etc., and achieves the elimination of separation and purification process and process operation Simplicity and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Construction of ectoine hydroxylase bacterial strain

[0032] ①A pair of primers were designed according to the sequence of the ectD gene by PCR technology, using the genome of Halomonas elongatus (CGMCC1.6329) as a template, and the ectD gene fragment was amplified. The pair of primers respectively comprise enzyme cutting sites NheI and HindIII.

[0033] ② Use Takara restriction endonucleases NheI and HindIII to double-digest step ① to obtain the target fragment and pET-his vector plasmid, and obtain ectD and pET-his linear fragments with the same cohesive ends.

[0034] ③ Use TakaraT4 DNA ligase to connect the two target fragments obtained in step ② to obtain the target vector pET-his-ectD.

[0035] ④ Transform the vector obtained in step ③ into E.coliBL-21 (ACCC11171) to obtain a ectoine hydroxylase-producing strain.

[0036] (2) Cell preparation with ectoine hydroxylase activity

[0037] ① Inoculate the above-mentioned strains into a 500ml round-bottomed Erle...

Embodiment 2

[0047] (1) For the construction of a strain producing ectoine hydroxylase, refer to Example 1.

[0048](2) Preparation of bacterial cells with ectohydropyrimidine hydroxylase activity, refer to Example 1.

[0049] (3) Catalytic synthesis of hydroxy ectoine using ectoine fermentation broth

[0050] ①Centrifuge the fermentation broth containing 5g / L ectoine, collect the supernatant, add 44mmol / L HEPES as a buffer, and finally adjust the pH to 7.0 with NaOH.

[0051] ② Prepare the reaction system, add 0.035mol / L α-ketoglutaric acid to the above fermentation broth, adjust the pH to 7.0 with NaOH, and then add the above-mentioned bacteria with ectoine hydroxylase activity in an amount of 30g / L.

[0052] ③The above reaction system was placed in a constant temperature water bath shaker at 40°C, and reacted at 200rpm for 24h.

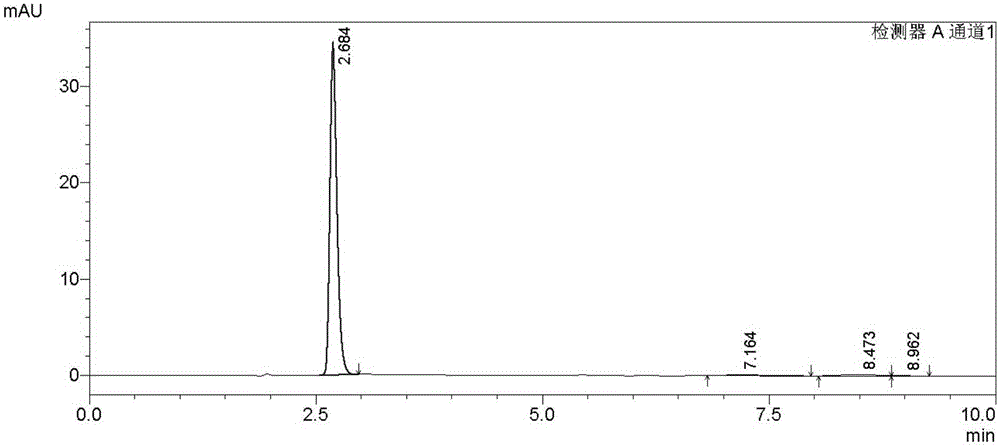

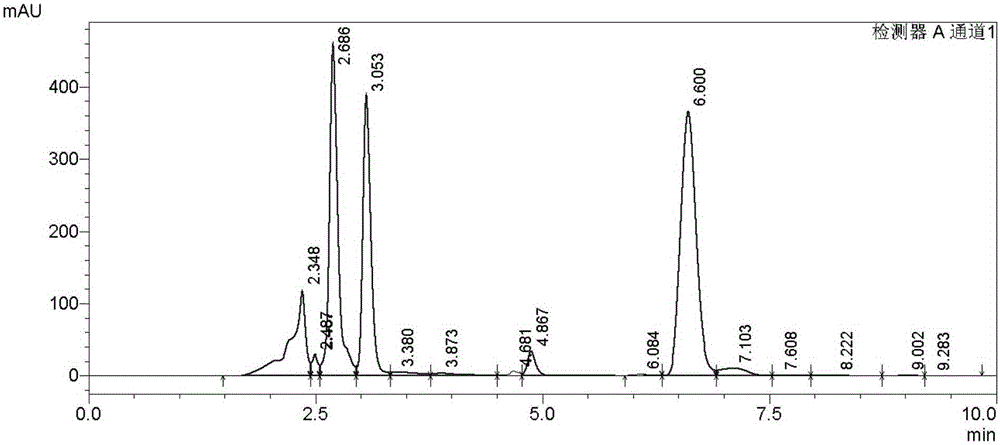

[0053] ④ Please refer to Example 1 for the liquid chromatography detection method. Detected by liquid chromatography, such as figure 1 and figure 2 Shown...

Embodiment 3

[0055] (1) For the construction of a strain producing ectoine hydroxylase, refer to Example 1.

[0056] (2) Preparation of bacterial cells with ectohydropyrimidine hydroxylase activity, refer to Example 1.

[0057] (3) Catalytic synthesis of hydroxy ectoine using ectoine fermentation broth

[0058] ①Centrifuge the fermentation broth containing 5g / L ectoine, collect the supernatant, add 44mmol / L HEPES as a buffer, and finally adjust the pH to 7.0 with NaOH.

[0059] ② Prepare the reaction system, add 0.035mol / L α-ketoglutaric acid to the above fermentation broth, adjust the pH to 7.0 with NaOH, and then add the above-mentioned bacteria with ectoine hydroxylase activity in an amount of 30g / L.

[0060] ③The above reaction system was placed in a constant temperature water bath shaker at 45°C, and reacted at 200rpm for 24h.

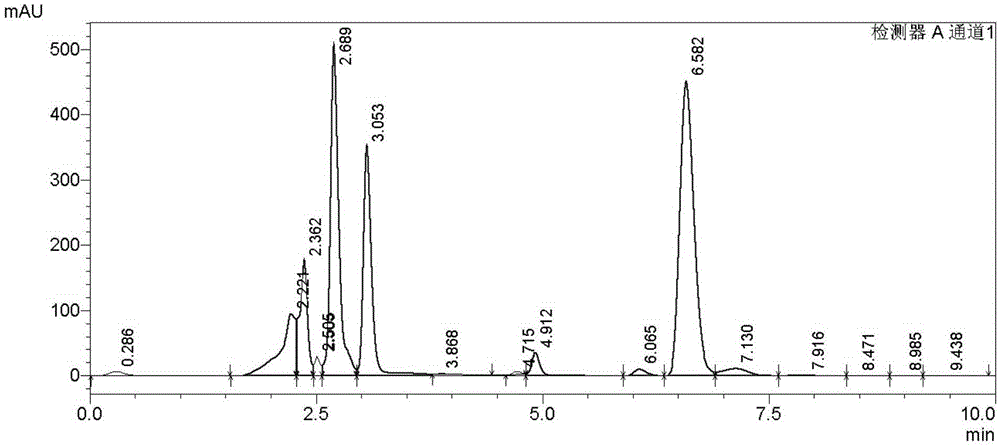

[0061] ④ Please refer to Example 1 for the liquid chromatography detection method. Detected by liquid chromatography, the hydroxyl in the reaction solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com