Waste and old oil well pipe performance recovery process

A technology for oil well pipes and waste, which is applied in the field of performance restoration of waste oil well pipes. It can solve the problems of high energy consumption in smelting waste oil well pipes, pollute the environment, and the inability to fundamentally restore the original specifications and mechanical properties of oil well pipes. The effect of tissue densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

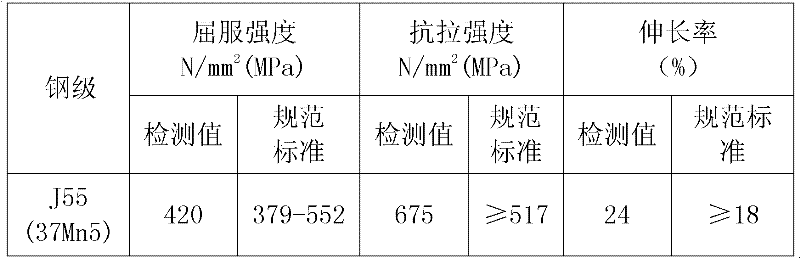

Examples

Embodiment Construction

[0028] The waste oil well pipe performance recovery process described in the present invention is as follows:

[0029] The first step, heat treatment: transport the waste oil well pipe to a multi-line roller hearth continuous heat treatment furnace for heating, the heating temperature is 860±10°C, during the heating process, the residual oil stain on the waste oil well pipe can be burned off, and the heated The waste oil well pipe is transported to the cooling table for natural cooling, and after cooling, it is straightened by a straightening machine to loosen the residues on the inner and outer surfaces of the waste oil well pipe, and an air compressor is used to blow high pressure on the inner and outer surfaces of the waste oil well pipe, and the above The residues are completely removed;

[0030] The second step, sorting treatment: check the waste oil well pipes processed in the first step, and cut off the waste oil well pipes whose inner wall wear depth is ≥ 3mm; the wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com