Easily-degradable alkali-free viscosity reducer for thick oil and preparation method thereof

A heavy oil viscosity reducer, easy to degrade technology, applied in the field of heavy oil viscosity reducer, easy to degrade alkali-free heavy oil viscosity reducer, can solve the problems of corrosion, difficult to degrade, unfavorable demulsification and dehydration, etc. Good capacity, fast biodegradation rate, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides an easily degradable alkali-free heavy oil viscosity reducer, which is prepared according to the following steps:

[0033] Under normal pressure, first add 55g of water into a four-necked flask equipped with an electric heating mantle, start the stirrer, adjust the rotation speed to 60-120 rpm, and raise the temperature at the same time, and the temperature is controlled at about 65°C;

[0034] Then slowly add L6415g, fatty alcohol ammonium sulfate 15g, lauryl alcohol 5g, fatty alcohol polyoxyethylene ether 10g in order, and mix and stir through 60-90 minutes, promptly obtain 100g active ingredient content and be 45wt% (mass percentage) Viscosity reducer.

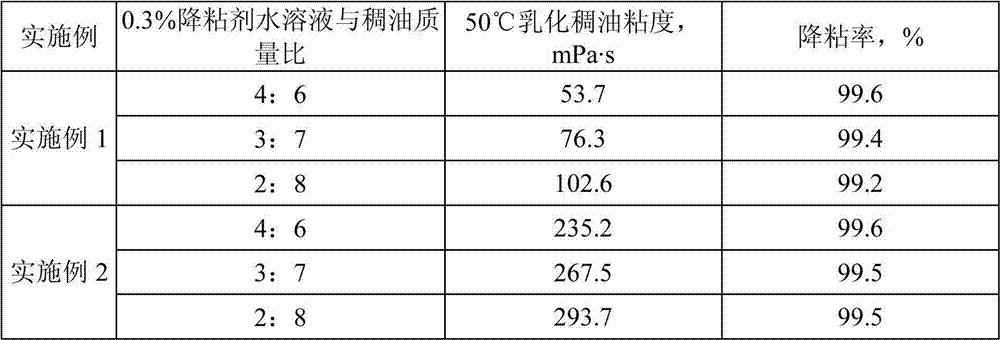

[0035]Weigh 60g, 70g, 80g of dehydrated extra heavy oil with a viscosity of 12730mPa·s at 50°C, add 40g, 30g, 20g of the aqueous solution containing 0.3% (mass percentage) of the viscosity reducing agent of this embodiment respectively, and stir at 50°C After 1 minute, three parts of emulsif...

Embodiment 2

[0037] This embodiment provides an easily degradable alkali-free heavy oil viscosity reducer, which is prepared according to the following steps:

[0038] Under normal pressure, first add 40g of water into a four-necked flask equipped with an electric heating mantle, start the stirrer, adjust the speed to 60-120 rpm, and raise the temperature at the same time, and control the temperature at about 65°C;

[0039] Then slowly add L6425g, fatty alcohol ammonium sulfate 25g, lauryl alcohol 4g, fatty alcohol polyoxyethylene ether 6g in order, and through mixing and stirring for 60-90 minutes, 100g of active ingredient content is 60wt% (mass percentage) Viscosity reducer, denoted as J-2.

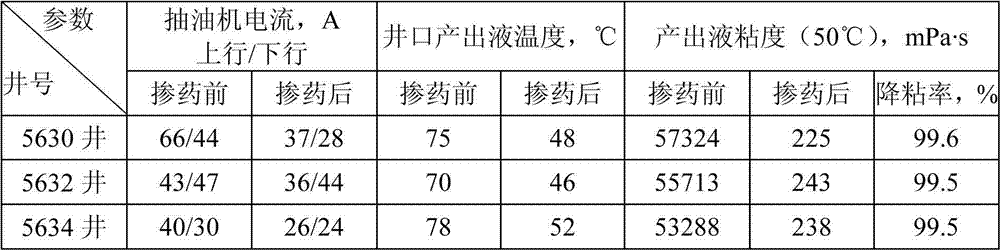

[0040] Weigh 60g, 70g, 80g of dehydrated super heavy oil with a viscosity of 57320mPa·s at 50°C, add 40g, 30g, 20g of the aqueous solution containing 0.3% (mass percentage) of the viscosity reducing agent of this embodiment respectively, and After stirring for 1 minute, three parts of emulsified h...

Embodiment 3

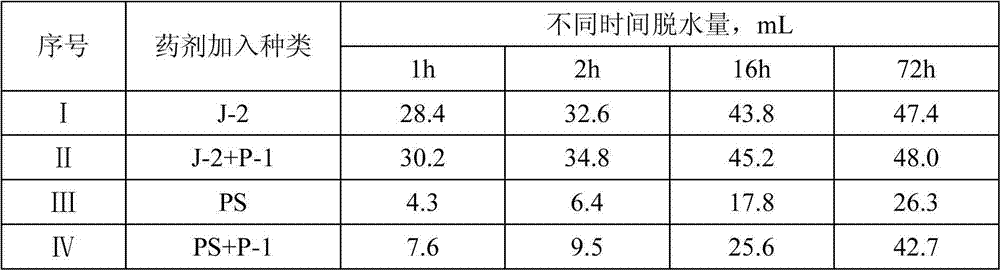

[0045] In this embodiment, the demulsification and dehydration performance test is carried out on the viscosity reducer prepared in Example 2, which specifically includes the following steps:

[0046] Measure four parts of ordinary heavy oil (water content 28wt%) with a viscosity of 2180mPa·s at 50°C and contain bound water, each part is 70mL, numbered I, II, III, IV respectively;

[0047] In I, II, add the viscosity reducer J-2 concentration that embodiment 2 prepares to be the aqueous solution 30mL of 0.3% (mass percentage), in III, IV, add PS viscosity reducer (produced by Huayou Industrial Company of Liaohe Oilfield) 0.3 % (mass percentage) aqueous solution of 30mL, stirred at 50°C for 1 minute, after all the emulsions are formed, then add 2-3 drops of demulsifier P-1 (TR-DEM / LY-IV type) to II and IV respectively Water-soluble crude oil demulsifier, produced by Liaohe Oilfield Huayou Hongshan Chemical Factory), mix and stir evenly, then quickly transfer I, II, III, and IV ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com