Middle-temperature high-aluminum reinforced porcelain and process for producing same

A technology of strengthening porcelain and high alumina, which is applied in the field of medium-temperature high-alumina strengthening porcelain and its production technology, can solve the problem of high energy consumption, achieve the effect of reducing firing temperature and improving internal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A medium-temperature high-alumina strengthened porcelain, which is composed of the following components (by weight): 15% of Datong soil, 10% of weathered potassium feldspar, 11% of alumina, 24% of Hunan washing mud, 2% of Jiangxi lithium porcelain stone powder, and Hunan black Feldspar 10%, calcined talc 3%, Jiepai soil 14%, quartz 8%, Guizhou soil 3%.

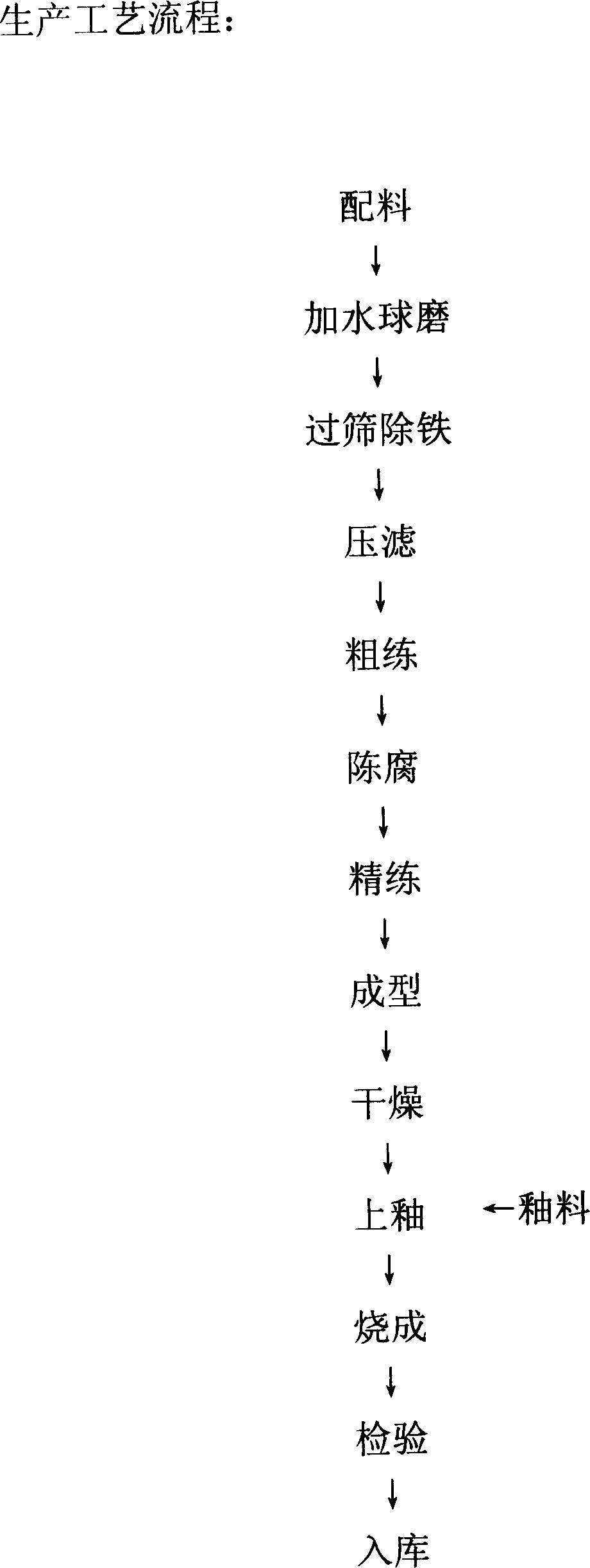

[0014] After batching according to the above ratio, put it into a ball mill and add water to ball mill, sieve to remove iron, press filter, rough smelt, stale, scouring, molding, drying, glazing, firing, inspection, packaging.

[0015] Said billet is added water ball mill according to material: ball: water=1.0:1.9:1.0 weight ratio adds water, ball milling time is 20 hours, ball milling fineness is less than 0.1% by sieve remaining 250 orders, and sieve remaining 325 orders is less than 0.3%; The sieve is 200 mesh; the Gauss intensity of the iron removal is 10000 Gauss intensity, and it is continuously sieved for 3 times...

Embodiment 2

[0018] A medium-temperature high-alumina strengthened porcelain, which is composed of the following components (by weight): 20% of Datong soil, 5% of weathered potassium feldspar, 15% of alumina, 15% of Hunan washing mud, 2% of Jiangxi lithium porcelain stone powder, and Hunan black Feldspar 9%, calcined talc 5%, Jiepai soil 20%, quartz 5%, Guizhou soil 4%.

[0019] After batching according to the above ratio, put it into a ball mill and add water to ball mill, sieve to remove iron, press filter, rough smelt, stale, scouring, molding, drying, glazing, firing, inspection, packaging.

[0020] Add water ball mill to the blank according to material: ball: water=1.0: 2.0: 1.2 weight ratio and add water, ball milling time is 20 hours, ball milling fineness is less than 0.1% by sieve remaining 250 mesh, and sieve residue 325 mesh is less than 0.3%; The sieve is 200 mesh; the Gauss intensity of the iron removal is 10000 Gauss intensity, and it is continuously sieved for 3 times; the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com