Single-point feeding control method of feeder of aluminum electrolytic cell

An aluminum electrolytic cell and single-point control technology, which is applied in the field of blanking, can solve problems such as control errors, poor control effect of alumina concentration, and frequent effects, so as to improve the control accuracy of blanking and avoid precipitation or frequent effects , The effect of improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

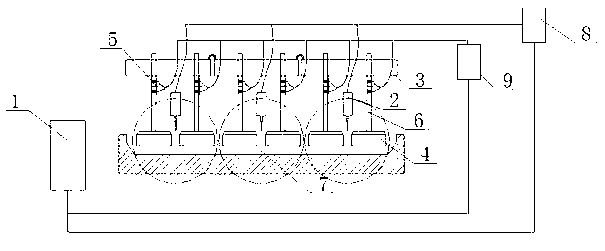

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] As shown in the figure, the single-point control blanking method of the aluminum electrolytic cell feeder of the present invention divides the feed port into different areas, collects equidistant pressure drop signals on the anode guide rods in different areas, and according to the equidistant pressure drop The signal is used to calculate the anode current, and the alumina concentration in each feeding port area is compared with each other according to the change trend of the anode current, and the feeding control is carried out according to the state of each feeding port area.

[0013] When the anode current in a certain blanking area decreases significantly, it means that the alumina concentration in this area is lower than the average alumina concentration of the whole tank; when the anode current in a certain blanking area increases significantly, it means that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com