Silane crosslinked halogen-free flame-retardant ethylene-propylene insulating material and preparation method thereof

A technology of silane cross-linking and ethylene propylene insulation, which is applied to insulators, insulated conductors, insulated cables, etc., can solve the problems of large energy consumption, large waste, and complicated procedures, so as to reduce investment costs, simplify production procedures, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

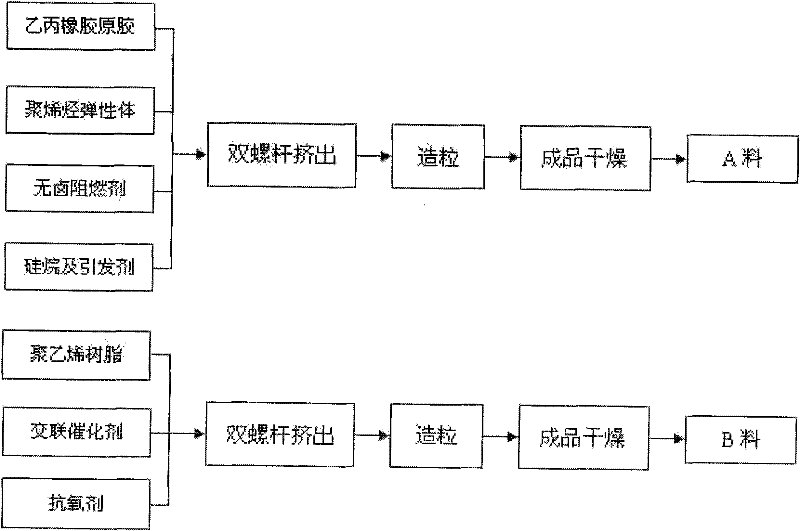

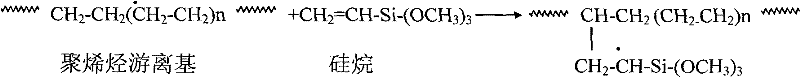

Method used

Image

Examples

Embodiment 1

[0061] Material A and material B are composed of 95:5 by weight:

[0062] A material component name and the weight ratio of each component are:

[0063] EPDM (ENB) 88kg;

[0064] Polyolefin elastomer (KF360) 12kg;

[0065] Vinyltriethoxysilane 1.5kg;

[0066] Organotin initiator dicumyl peroxide DCP 0.11kg;

[0067] Halogen-free flame retardant Mg(OH) 2 112kg;

[0069] B material component name and the weight ratio of each component are:

[0070] Polyethylene resin LDPEDJ210 100kg;

[0071] Antioxidant B215 6kg;

[0072] Cross-linking catalyst dibutyltin maleate laurate 1.1kg.

[0073] Production process: Mix material A and material B evenly at a weight ratio of 95:5, extrude through a single screw to make a test piece, and place it at room temperature for 3 to 5 days;

[0074] The production process of material A is: raw rubber of EPDM (ENB), polyolefin elastomer (KF360) and halogen-free flame retardant Mg(OH) 2 Mix evenly...

Embodiment 2

[0077] Material A and material B are composed of 95:5 by weight:

[0078] A material component name and the weight ratio of each component are:

[0079] EPDM (DCPD) 91kg;

[0080] Polyolefin elastomer (DF840) 9kg;

[0081] Vinyltrimethoxysilane 1.7kg;

[0082] Organotin initiator dibenzoyl peroxide BPO 0.14kg;

[0083] Halogen-free flame retardant Al(OH) 3 128kg;

[0084] Lubricant EBS 9kg.

[0085] B material component name and the weight ratio of each component are:

[0086] Polyethylene resin LDPE5320 100kg;

[0087] Antioxidant 168 9kg;

[0088] Cross-linking catalyst dilauric acid 1.4kg.

[0089] Production process: Mix material A and material B evenly at a weight ratio of 95:5, extrude through a single screw to make a test piece, and place it at room temperature for 3 to 5 days;

[0090] The production process of material A is: raw rubber of EPDM (DCPD), polyolefin elastomer (DF840) and halogen-free flame retardant Al(OH) 3 Mix evenly for 5 min...

Embodiment 3

[0093] Material A and material B are composed of 95:5 by weight:

[0094] A material component name and the weight ratio of each component are:

[0095] EPDM (ENB) 90kg;

[0096] Polyolefin elastomer (KF360) 10kg;

[0097] Vinyltrichlorosilane 1.6kg;

[0098] Initiator Shuang25 0.13kg;

[0099] Halogen-free flame retardant Mg(OH) 2 120kg;

[0100] Lubricant magnesium stearate 7kg.

[0101] B material component name and the weight ratio of each component are:

[0102] Polyethylene resin LDPE2102 100kg;

[0103] Antioxidant 1076 8kg;

[0104] Cross-linking catalyst dibutyltin silicate 1.2kg.

[0105] Production process: Mix material A and material B evenly at a weight ratio of 95:5, extrude through a single screw to make a test piece, and place it at room temperature for 3 to 5 days;

[0106] The production process of material A is: raw rubber of EPDM (ENB), polyolefin elastomer (KF360) and halogen-free flame retardant Mg(OH) 2 According to the proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com