Method for desulphurizing sulfur-containing flue gas with coking crude gas water-washing deaminized ammonia water

A crude gas and water elution technology, applied in chemical instruments and methods, separation methods, applications, etc., can solve the problems of high operating costs, large investment, and low added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

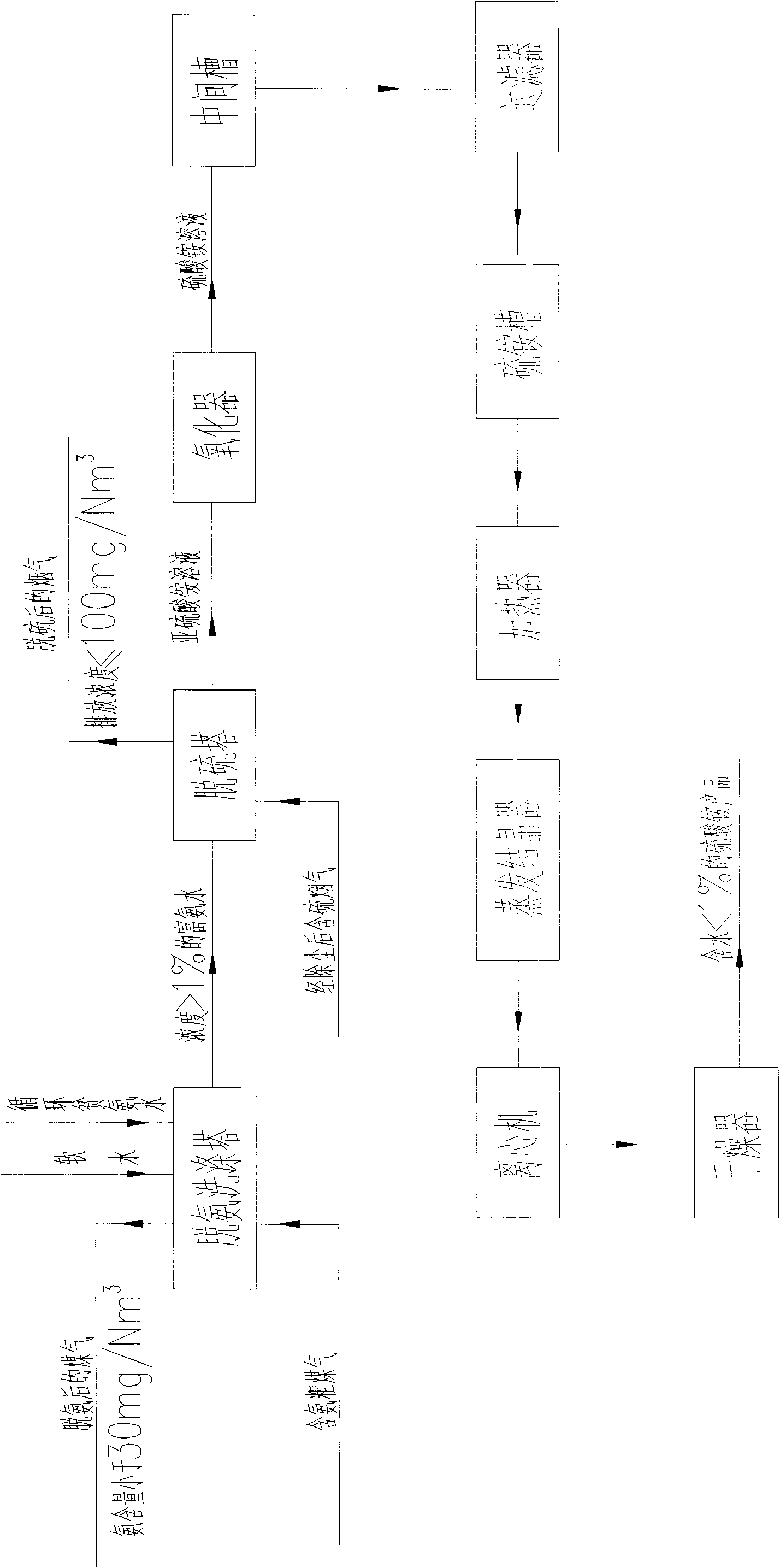

[0017] like figure 1 After the coke oven crude gas is desulfurized, the temperature is about 25°C, and it enters the tower from the bottom of the deammonization scrubber. At the same time, soft water and circulating lean ammonia water are sprayed down from the top of the deammonization scrubber to wash the crude gas. Ammonia, until the ammonia content in the gas is less than 30mg / Nm 3 Finally, it is sent out of the deammonization washing tower, and the rich ammonia water with an ammonia concentration of more than 1% after ammonia washing is also discharged out of the tower.

[0018] The sulfur-containing flue gas from the boiler or other places is sent to the desulfurization tower from the bottom of the desulfurization tower through the fan after being dedusted by the dust collector, and at the same time, the above-mentioned ammonia-rich water after ammonia washing is sprayed into the tower from the top , in the process of falling, it is in reverse contact with the bottom-up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com