Annealing process and equipment for foamed glass blank

A technology of foam glass and annealing equipment, which is applied in the field of annealing process and annealing equipment of foam glass blanks, which can solve the problems of uneven heat dissipation of blanks, inability to mix uniform hot air flow, large temperature difference, etc., and achieve the effect of convenient and independent temperature control

Active Publication Date: 2008-11-19

ZHEJIANG ZHENSHEN INSULATION TECH CORP

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The heating device arrangement of the existing kiln is that the burner is installed at the lower part of the furnace entrance. The farther the burner is from the kiln, the less heat and the lower the temperature. The heating value of the nozzle and the length of the flame are used for trimming. It is difficult to adjust, and the operator needs to have rich experience.

The kiln does not have a hot air circulation system, the hot air in the furnace cannot be stirred evenly, the temperature difference between the top and the bottom of the furnace is large, and the uneven heat dissipation of the blank makes the blank easy to break, and it is impossible to anneal the high-performance foam glass blank with low thermal conductivity

In summary, the existing trolley-type annealing kiln has low efficiency and low qualified rate of finished products, and is not suitable for the production of high-performance foam glass

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

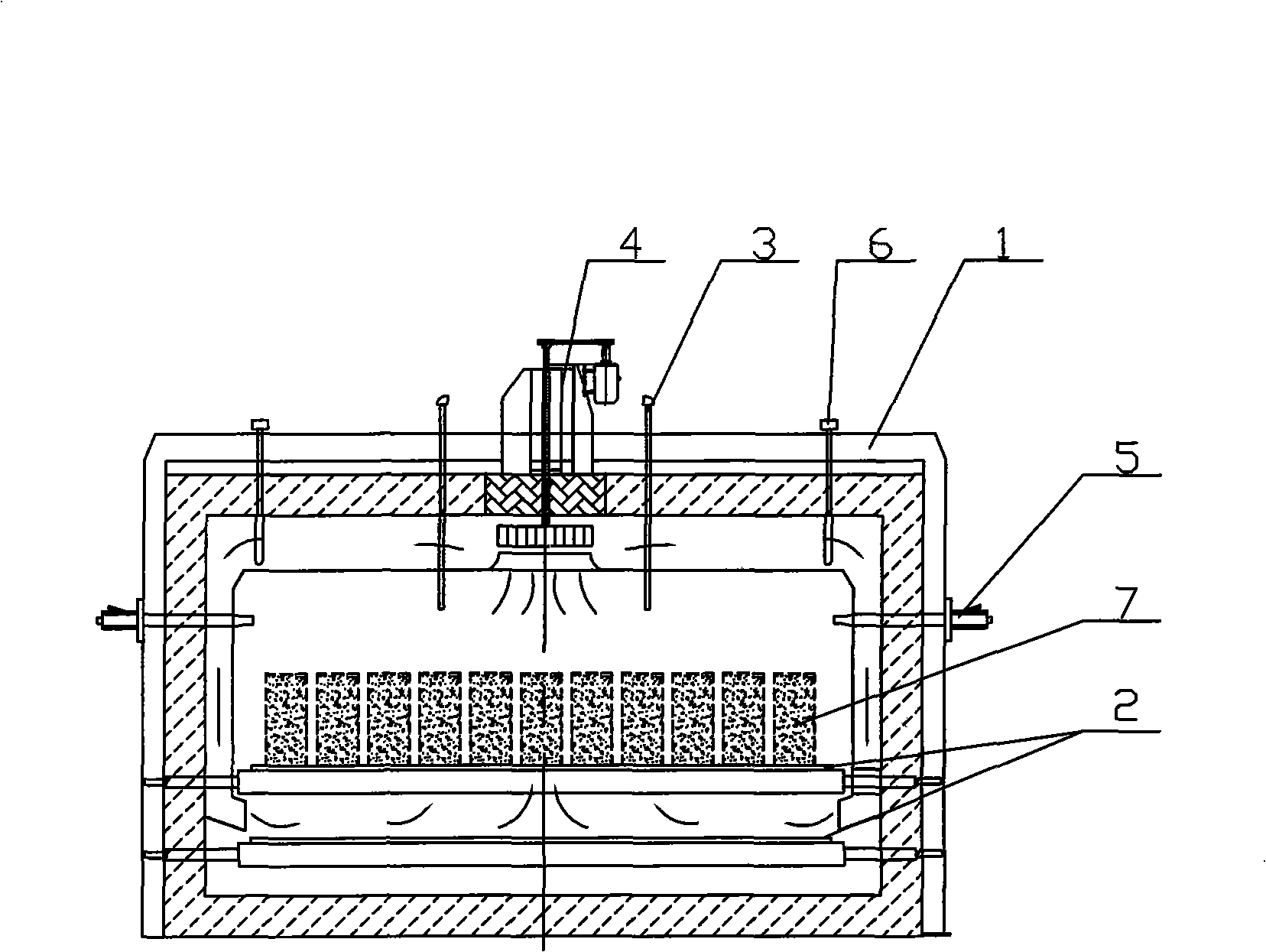

The invention relates to an annealing technique and an annealing device. The annealing technique for chunk foam glass is as follows: the annealing is performed in a kiln, and the chunk foam glass is annealed by adoption of the continuous mesh-belt conveying means; and the temperature of a hearth of the kiln is gradually reduced from the high temperature on an inlet to the normal temperature on an outlet. The annealing device for the chunk foam glass comprises the kiln, wherein, the inside of the furnace is provided with a continuous mesh-belt conveyer, provided with 20 to 50 temperature decreasing regions from the inlet to the outlet, and is also provided with a temperature control system. Due to adoption of continuous mesh-belt conveying of the chunk foam glass, continuous operation is realized; due to adoption of gradual temperature reduction in the kiln, the uniform annealing for a long time is realized, thereby high-performance foam glass with difficulty in fracture, high strength and low thermal conduction is produced; and due to arrangement of a plurality of temperature regions inside the furnace, the temperature is convenient to control independently.

Description

Annealing process and annealing equipment for foam glass blank (1) Technical field The invention relates to an annealing process and annealing equipment for foam glass blanks. (2) Background technology Foam glass is a new type of inorganic thermal insulation material with glass as the main raw material and a uniform independent air gap structure. It completely retains the chemical stability of inorganic glass, and has the characteristics of low bulk density, small thermal conductivity, non-combustibility, and high mechanical strength. Cellular glass has good thermal insulation properties that will not deteriorate in a wide temperature range from ultra-low to high temperatures. During the production process of foam glass, the foam glass blanks that reach a high temperature of about 560°C will gradually dissipate heat and cool down to normal temperature in the kiln under the corresponding temperature curve according to the difference in raw materials and sizes, in order to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B25/00

Inventor 曹原张春华张新湘张永福韦黎

Owner ZHEJIANG ZHENSHEN INSULATION TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com