Spheroidized annealing process for shortening annealing cycle of hot rolled wire rods

An annealing cycle, spheroidizing annealing technology, applied in the field of spheroidizing annealing process, hot-rolled wire rod annealing process, can solve the problems of slow cooling or annealing, long annealing holding time, affecting production efficiency, etc., to achieve high ductility, cold The effect of low forming crack rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

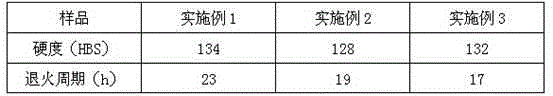

Embodiment 1

[0027] A kind of spheroidizing annealing process that shortens the annealing period of SCM435 hot-rolled wire rod, it comprises the steps:

[0028] A. Put the fastener wire made of SCM435 in a heat treatment furnace, fill the heat treatment furnace with industrial nitrogen with a purity of 99.99%, and raise the temperature in the furnace to 630°C at a rate of 100°C / hour. The protective atmosphere will be changed to continuous nitrogen + RX gas. When the temperature in the furnace rises to 680°C, turn off the industrial nitrogen, and only fill the heat treatment furnace with RX gas. Then raise the temperature in the furnace to 770°C and keep it for 3 hours. ;

[0029] B. Cooling in the first stage: Cool the temperature in the furnace to 710°C at a rate of 30°C / hour by air cooling, and keep it warm for 6 hours;

[0030] C. The second stage of cooling: continue to cool the temperature in the furnace to 665°C at a rate of 50°C / hour through air cooling, turn off the RX gas, and fi...

Embodiment 2

[0034] A kind of spheroidizing annealing process that shortens the annealing period of SCM435 hot-rolled wire rod, it comprises the steps:

[0035] A. Put the fastener wire made of SCM435 in a heat treatment furnace, fill the heat treatment furnace with industrial nitrogen with a purity of 99.99%, and raise the temperature in the furnace to 630°C at a rate of 120°C / hour. The input protective atmosphere will be changed to continuous nitrogen + RX gas. When the temperature in the furnace rises to 680°C, turn off the industrial nitrogen, and only fill the heat treatment furnace with RX gas, then raise the temperature in the furnace to 780°C and keep it for 1.5 hours ;

[0036] B. The first stage of cooling: Cool the temperature in the furnace to 720°C at a rate of 30°C / hour by air cooling, and keep it warm for 5 hours;

[0037] C. The second stage of cooling: continue to cool the temperature in the furnace to 665°C at a rate of 50°C / hour through air cooling, turn off the RX gas,...

Embodiment 3

[0041] A kind of spheroidizing annealing process that shortens the annealing period of SCM435 hot-rolled wire rod, it comprises the following steps successively:

[0042] A. Put the fastener wire made of SCM435 in a heat treatment furnace, fill the heat treatment furnace with industrial nitrogen with a purity of 99.99%, and raise the temperature in the furnace to 630°C at a rate of 140°C / hour. The protective atmosphere will be changed to continuous nitrogen + RX gas. When the temperature in the furnace rises to 680°C, turn off the industrial nitrogen, and only fill the heat treatment furnace with RX gas. Then raise the temperature in the furnace to 790°C and keep it for 1 hour. ;

[0043] B. The first stage of cooling: Cool the temperature in the furnace to 730°C at a rate of 30°C / hour by air cooling, and keep it warm for 4 hours;

[0044] C. The second stage of cooling: continue to cool the temperature in the furnace to 665°C at a rate of 50°C / hour through air cooling, turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com