Patents

Literature

44results about How to "Does not affect continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

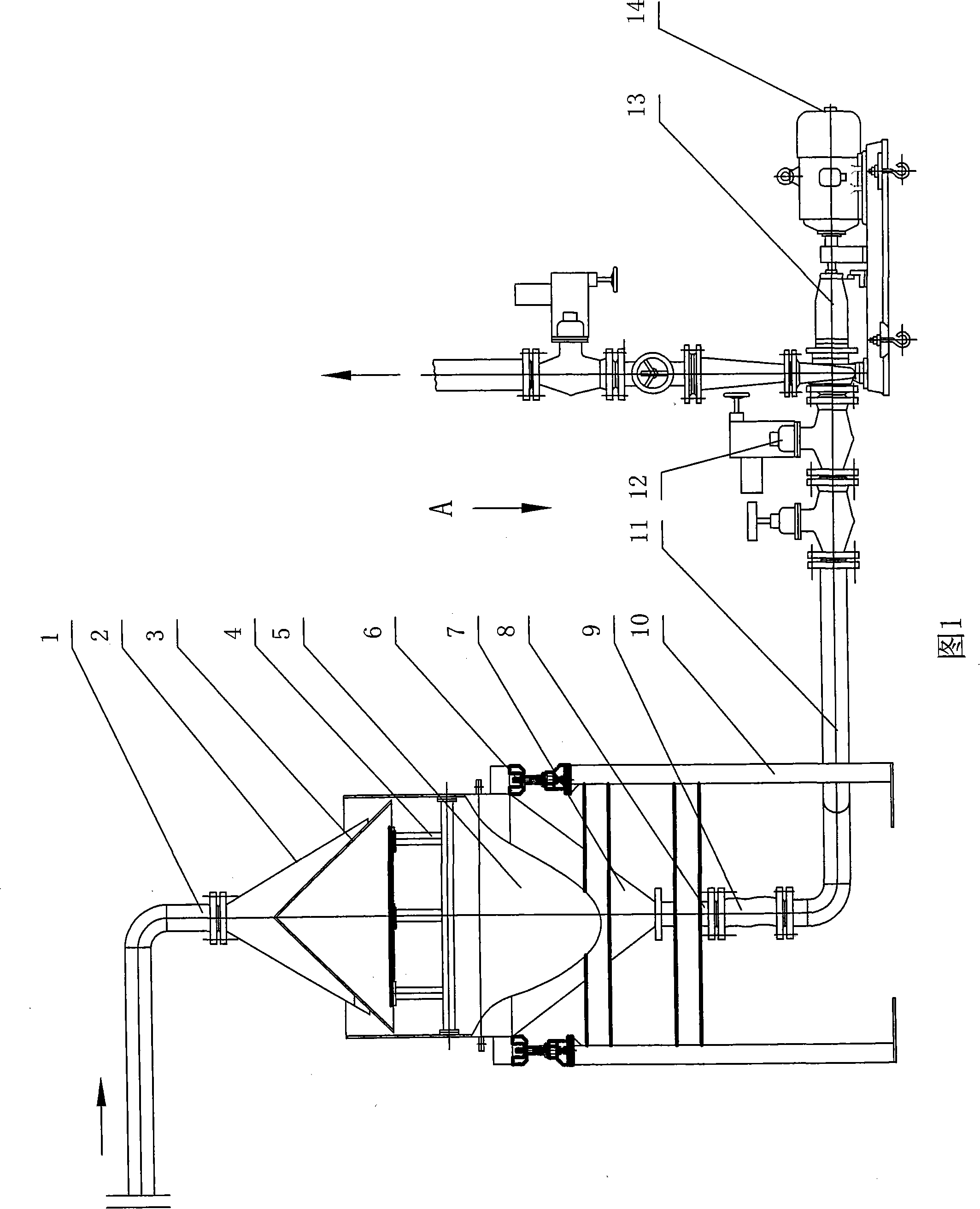

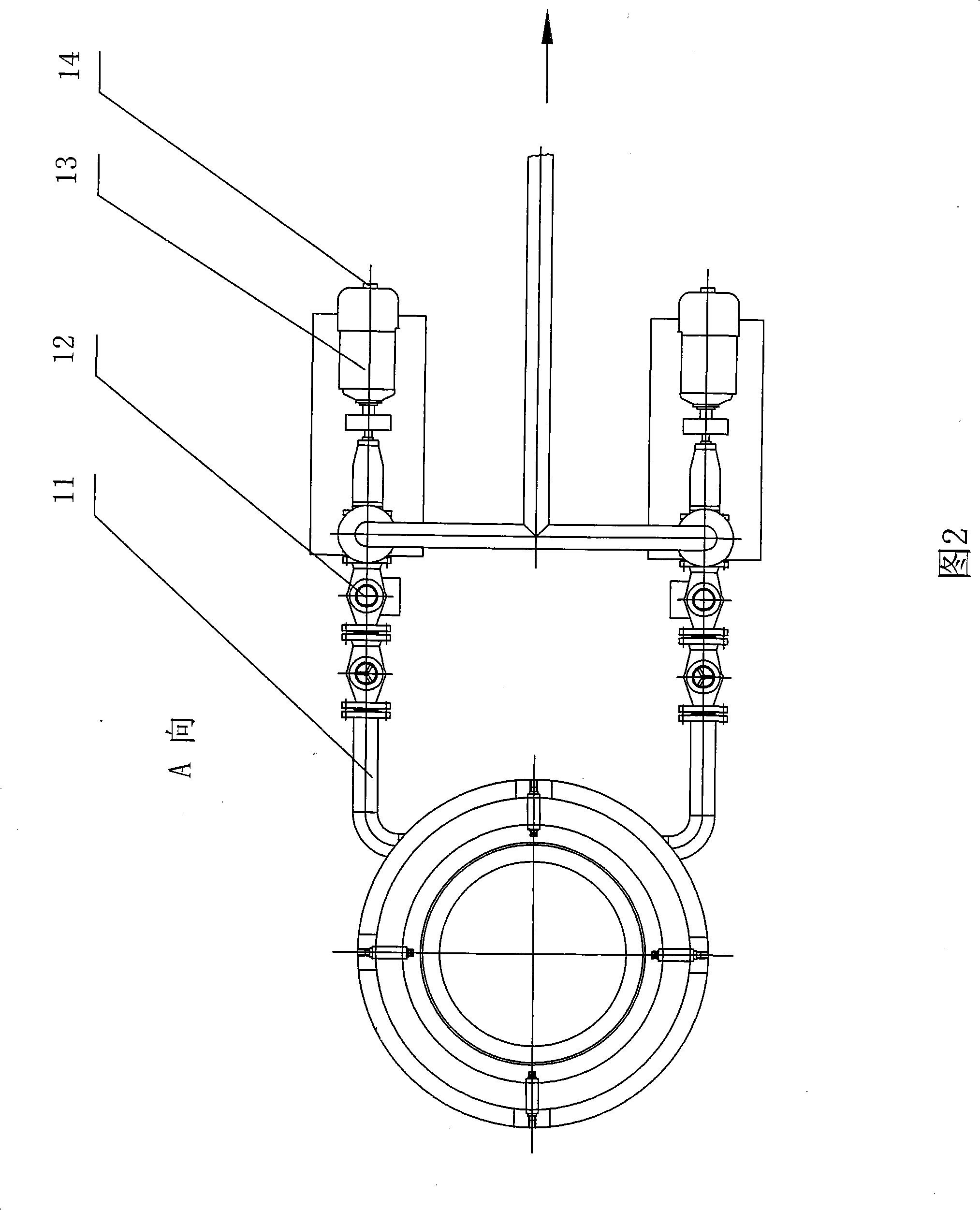

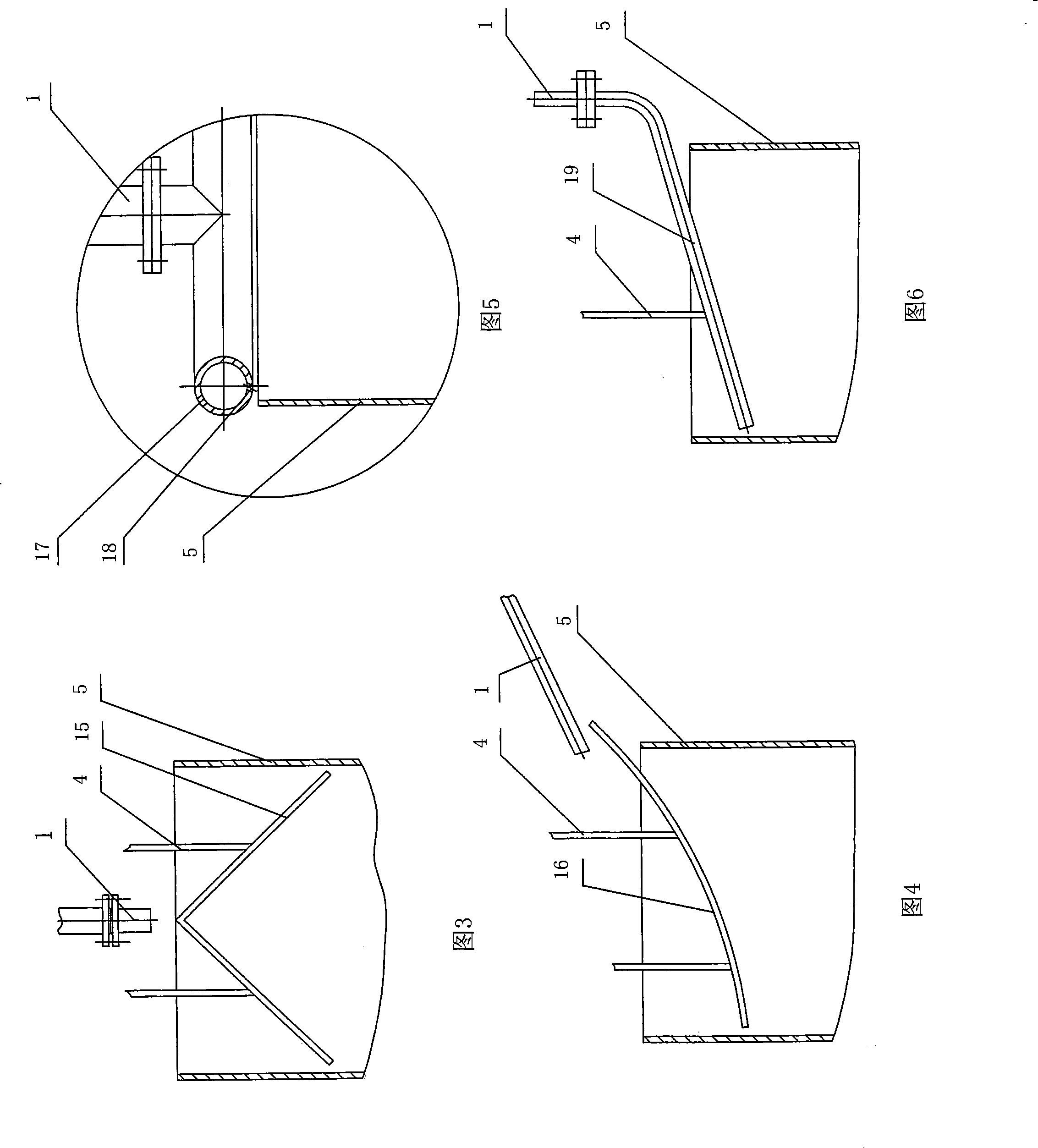

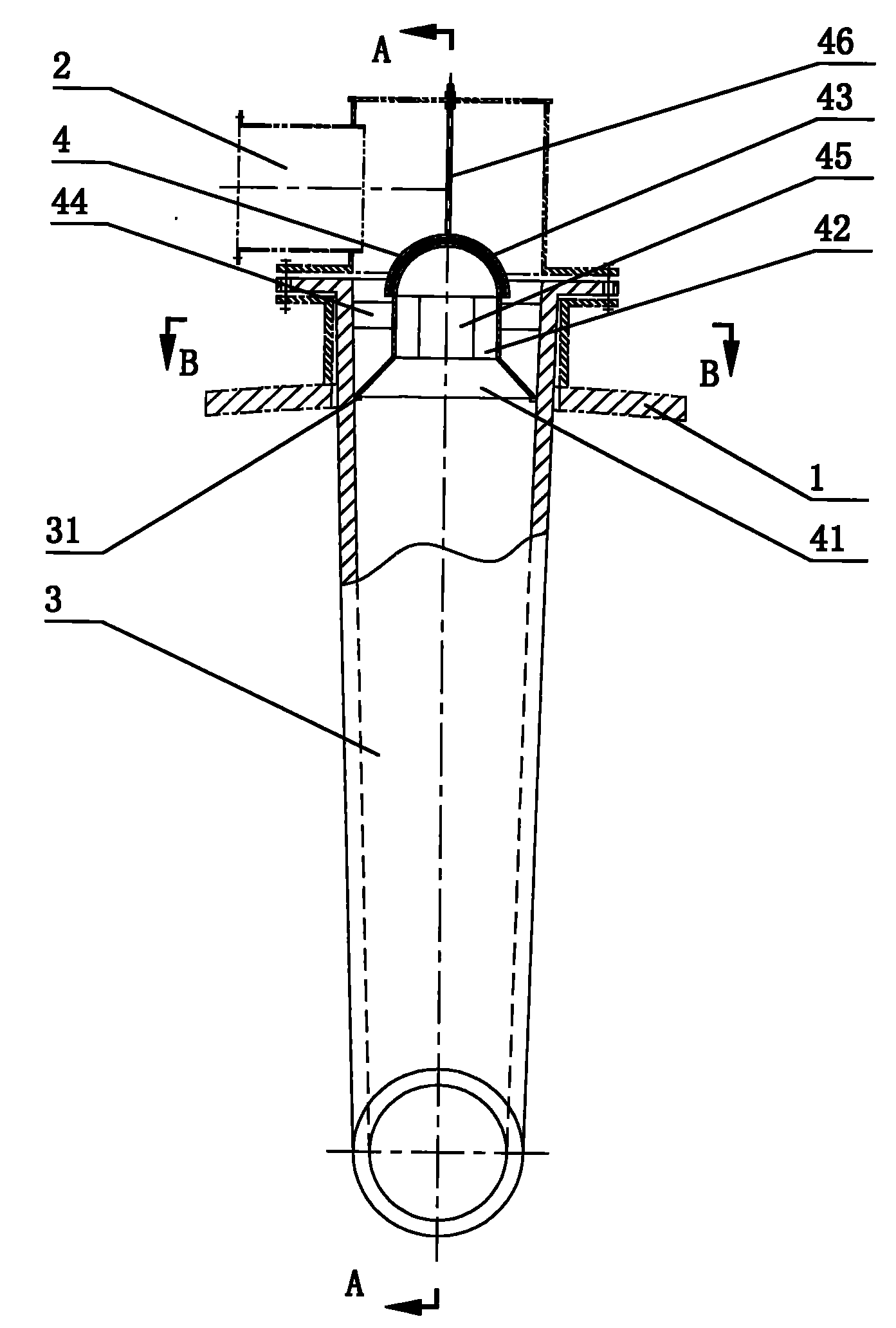

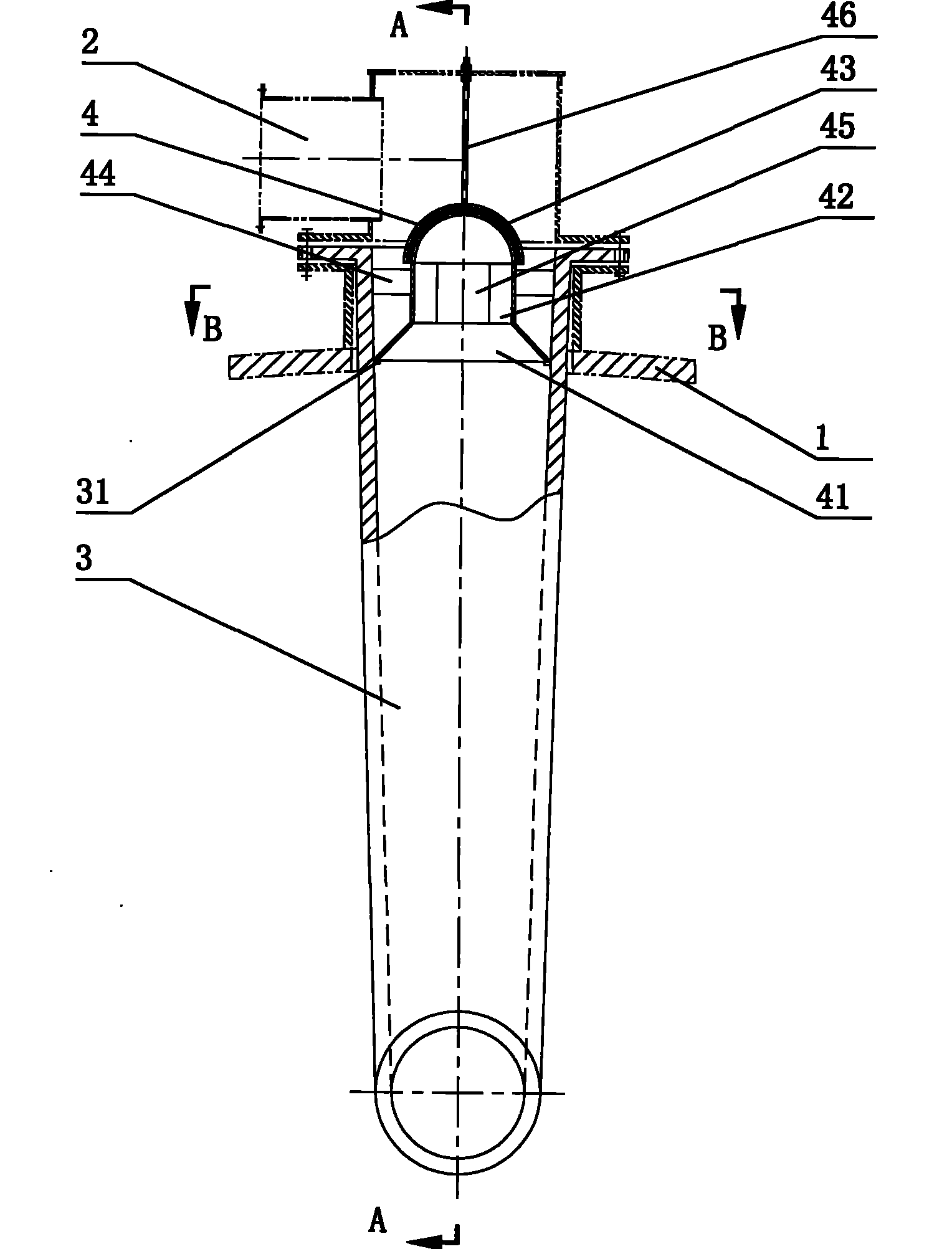

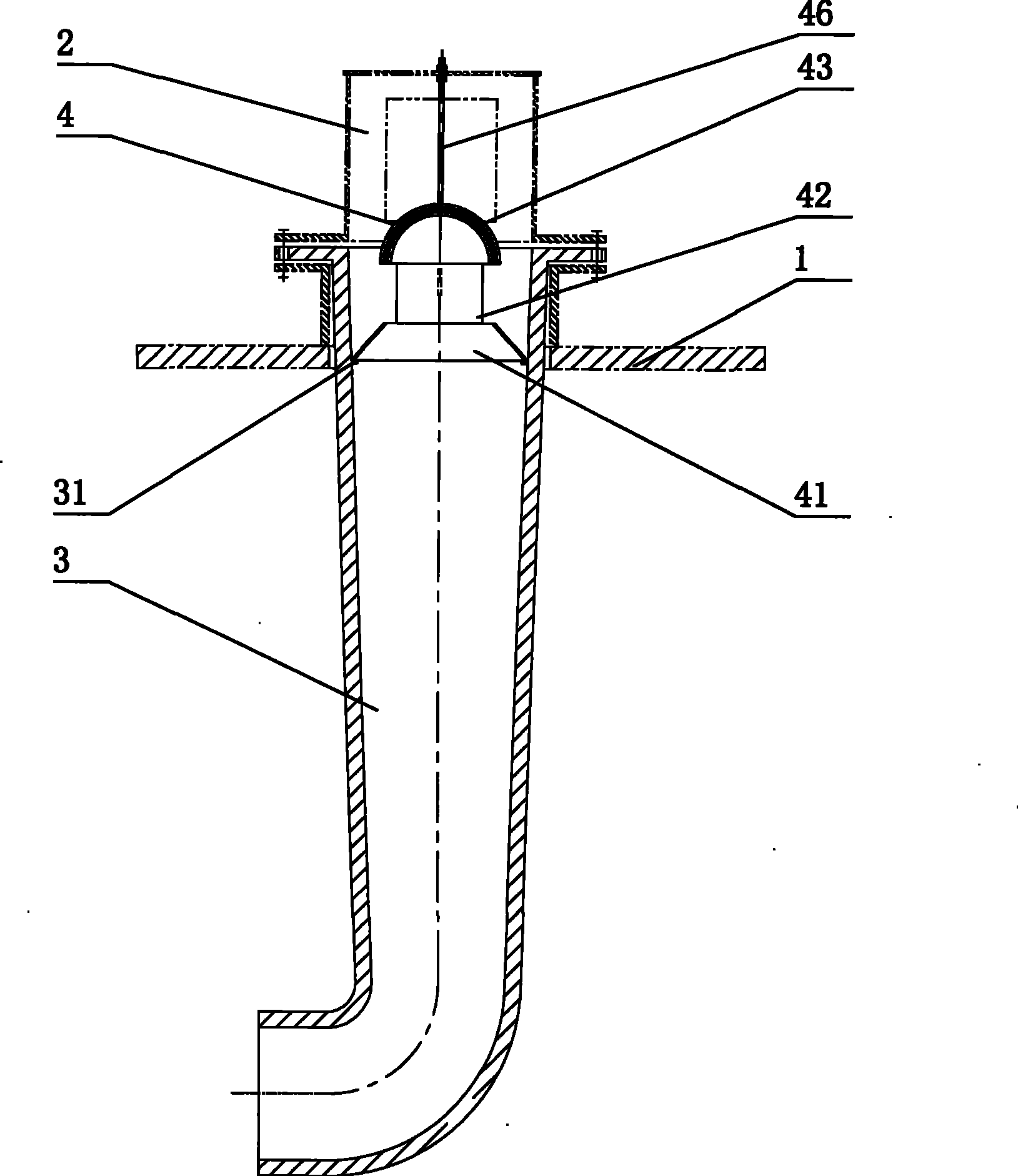

Mineral slurry flux on-line detecting device and multi-parameter on-line detecting integrated system

InactiveCN101251395AAccurate measurementEliminate wear and tearVolume/mass flow measurementMaterial analysis by electric/magnetic meansLiquid productMeasurement device

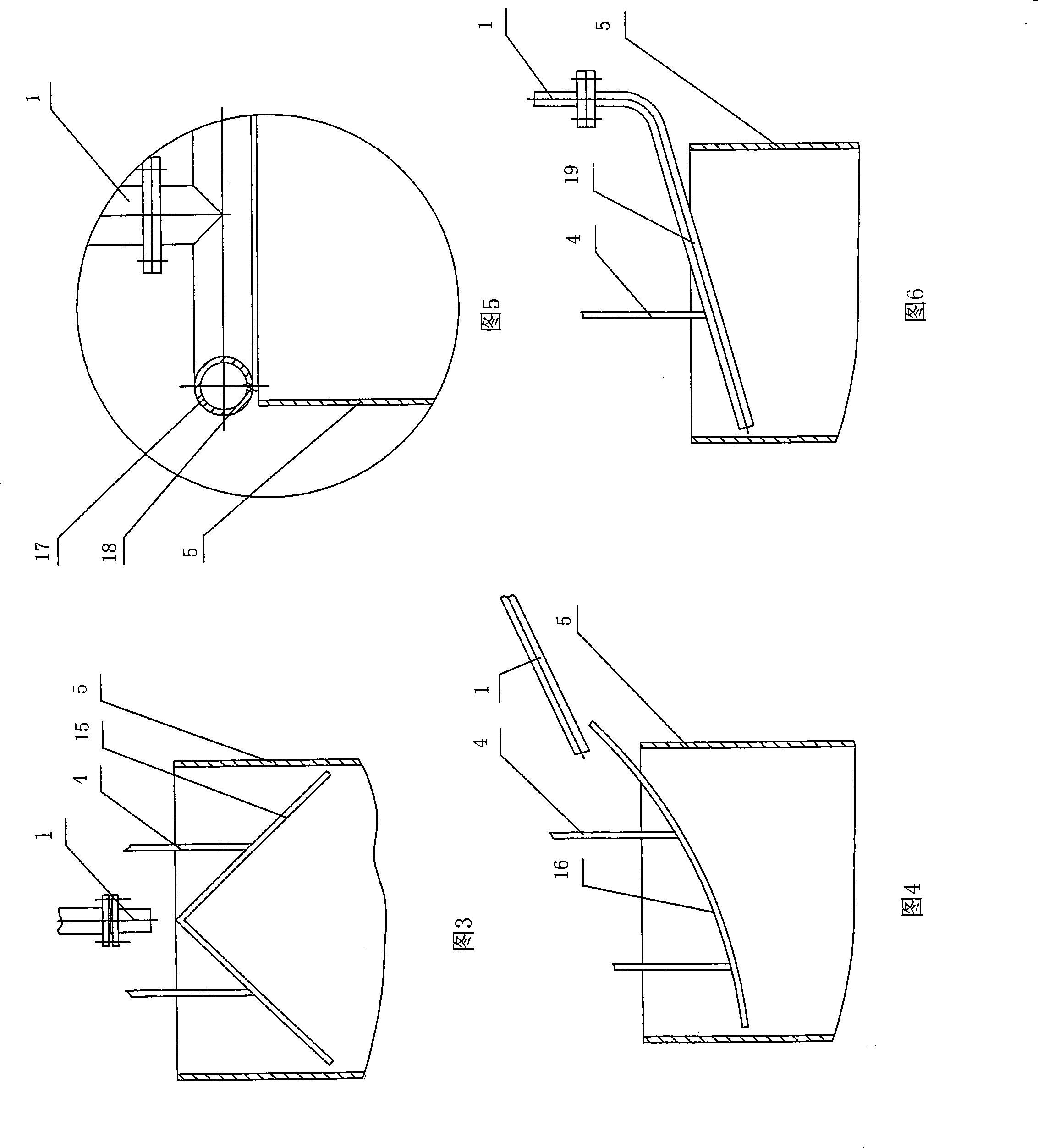

The invention provides an online detection device for the pulp flow rate and a multi-parameter online detection integration system, which comprise a pulp container which has a feed port and a discharge port and is arranged on a support through a, weighing cell, a pulp flow rate detection device which is provided with a soft connector at the discharge port, and / or a pulp density measuring device, a pulp grain size measuring device and a pulp grade measuring device. The online detection device for the pulp flow rate and a multi-parameter online detection integration system can not only measure any single index of the flow rate, density, grain size and grade of the pulp according to requirements, but also simultaneously measure two or above two or even all of the indexes with high measuring accuracy, good stability and reliability. The online detection device for the pulp flow rate and a multi-parameter online detection integration system also have the advantages of simple structure, high working efficiency, low labor intensity, wide application range, etc., thereby being capable of providing the highly reliable flow rate, density, grain size and grade control parameters for liquid products to ensure product quality, reduce cost and improve working efficiency, and providing a highly guaranteed measuring device and system for full automatic control.

Owner:罗放明

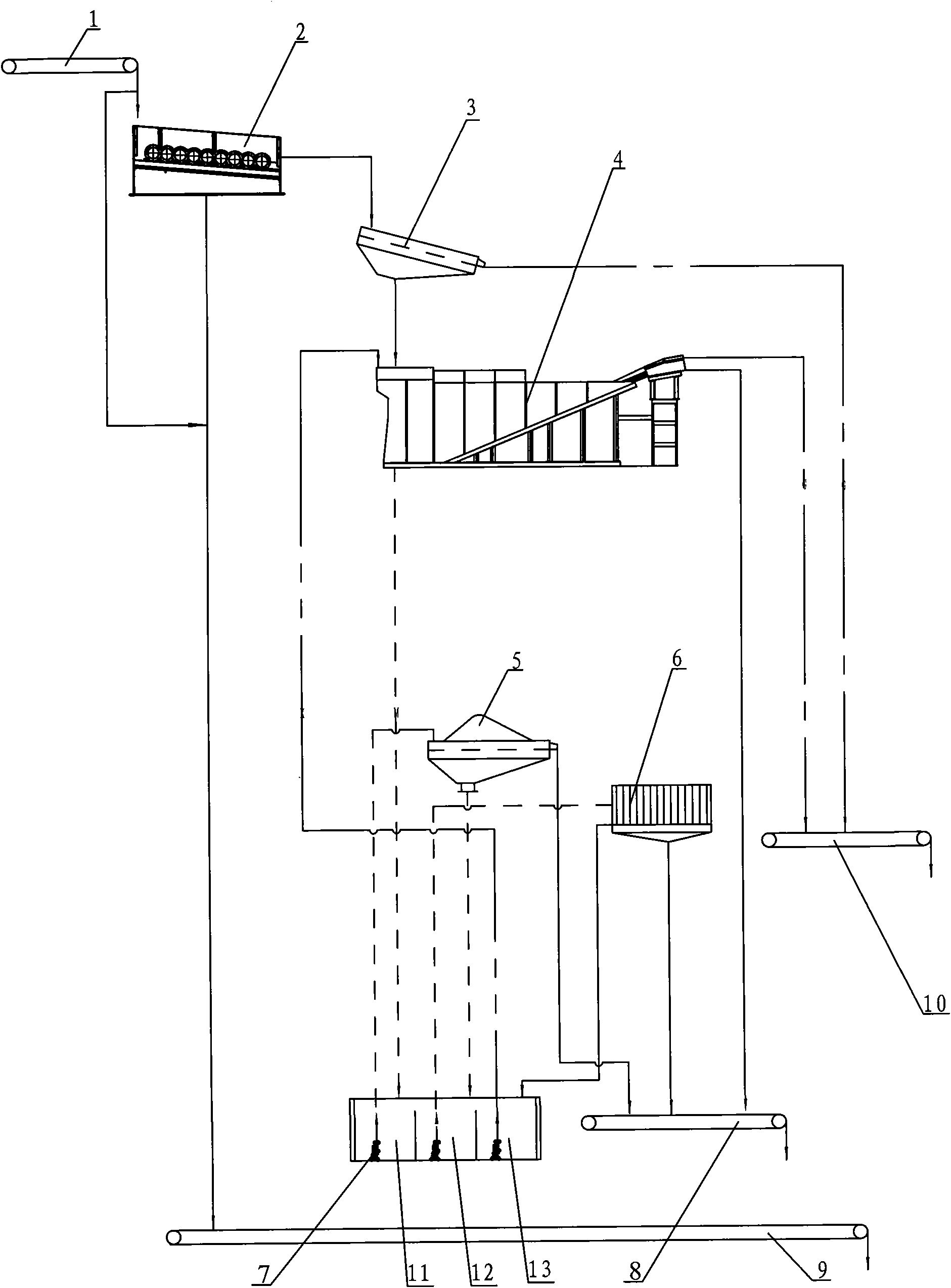

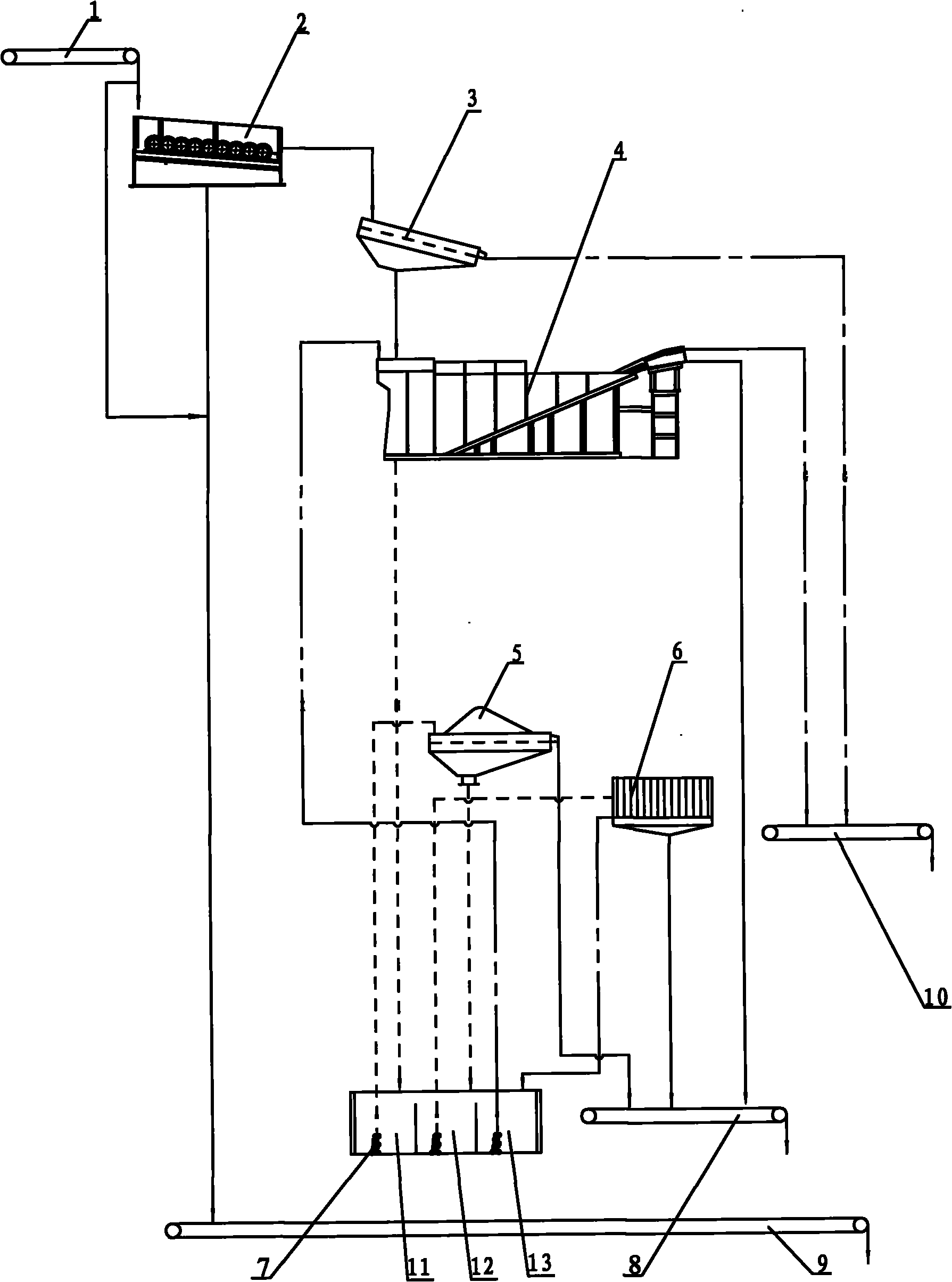

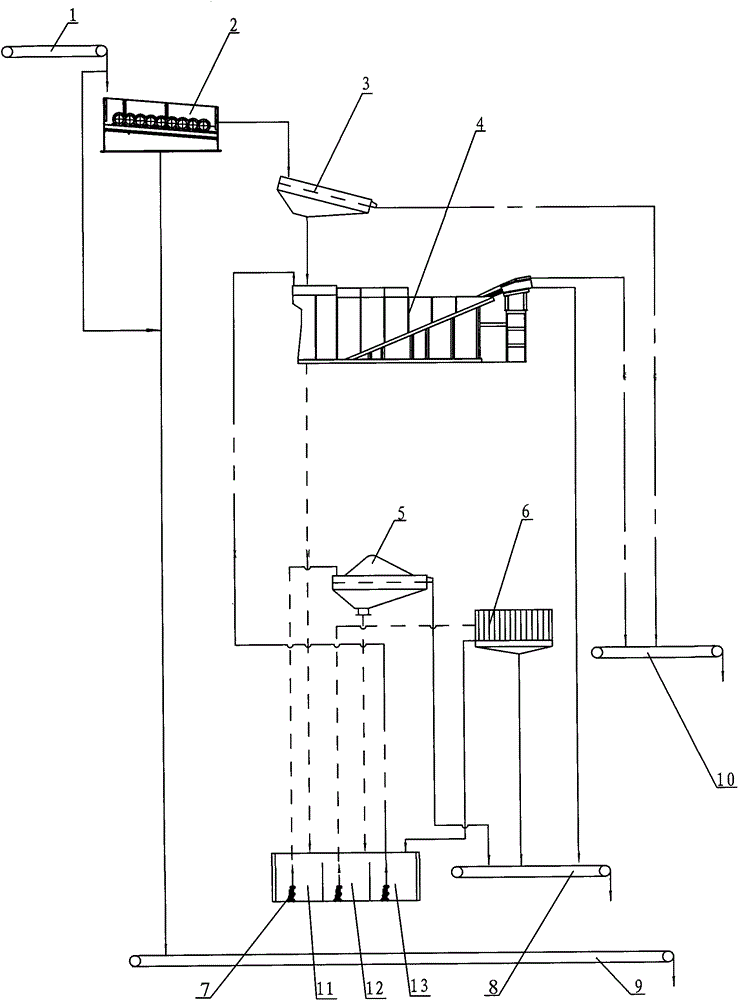

Waste rock discharging and sorting comprehensive treatment method for underground lump coal

The invention discloses a waste rock discharging and sorting comprehensive treatment method for underground lump coal, which comprises the following steps of: transporting raw coal of a mining area to a tunnel provided with a rolling disk screen through a raw coal incoming material belt machine to perform grading treatment; directly feeding the screened substances into an underground primary coal transportation belt machine, feeding the granular coal on the screen into a fixed grate screen, and feeding the screened coal into an underground mechanical movable sieve jig to perform sorting; conveying the sorted lump coal to a tunnel lump coal removal belt machine, and conveying the sorted lump waste rock to a tunnel lump waste rock removal belt machine till an underground waste tunnel or an underground waste rock filling system; and pumping the sorted coal slurry to a high-frequency screen through a coal slurry pump to intercept coarse coal, then dehydrating the coal slurry, and recycling filtrate so as to realize closed cycle of washing water. The method discharges waste rocks from the lump coal by adopting the underground mechanical movable sieve jig adaptive to the underground tunnel chamber operation, occupies a little space, is convenient for mounting and underground chamber operation, has simple process flow, can effectively reduce pollution, is favorable for environmental protection, saves a large amount of resources, saves manpower and resources, and remarkably improves the sorting operation efficiency and the lump coal yield.

Owner:SHENYANG TIAN AN TECH CO LTD

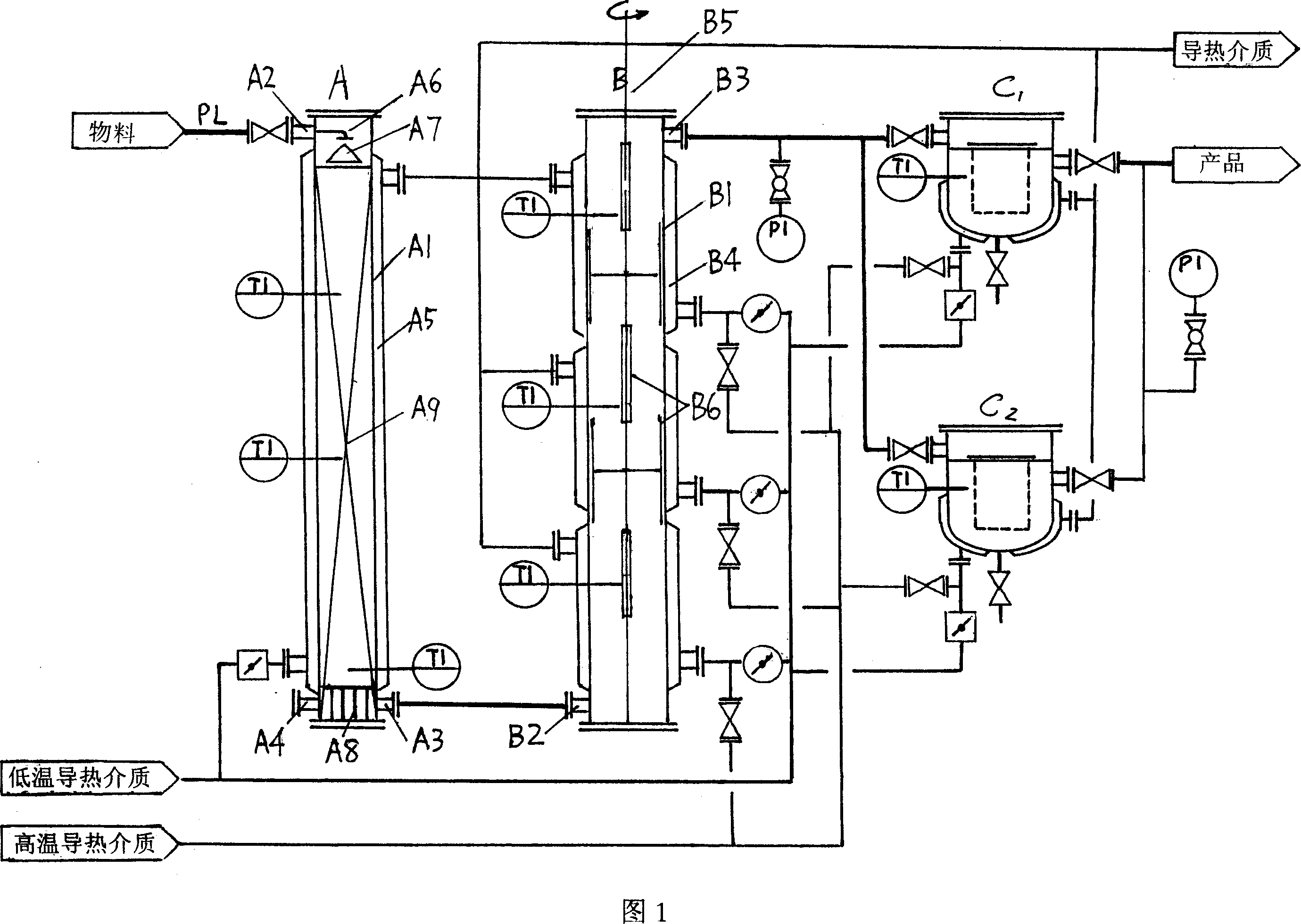

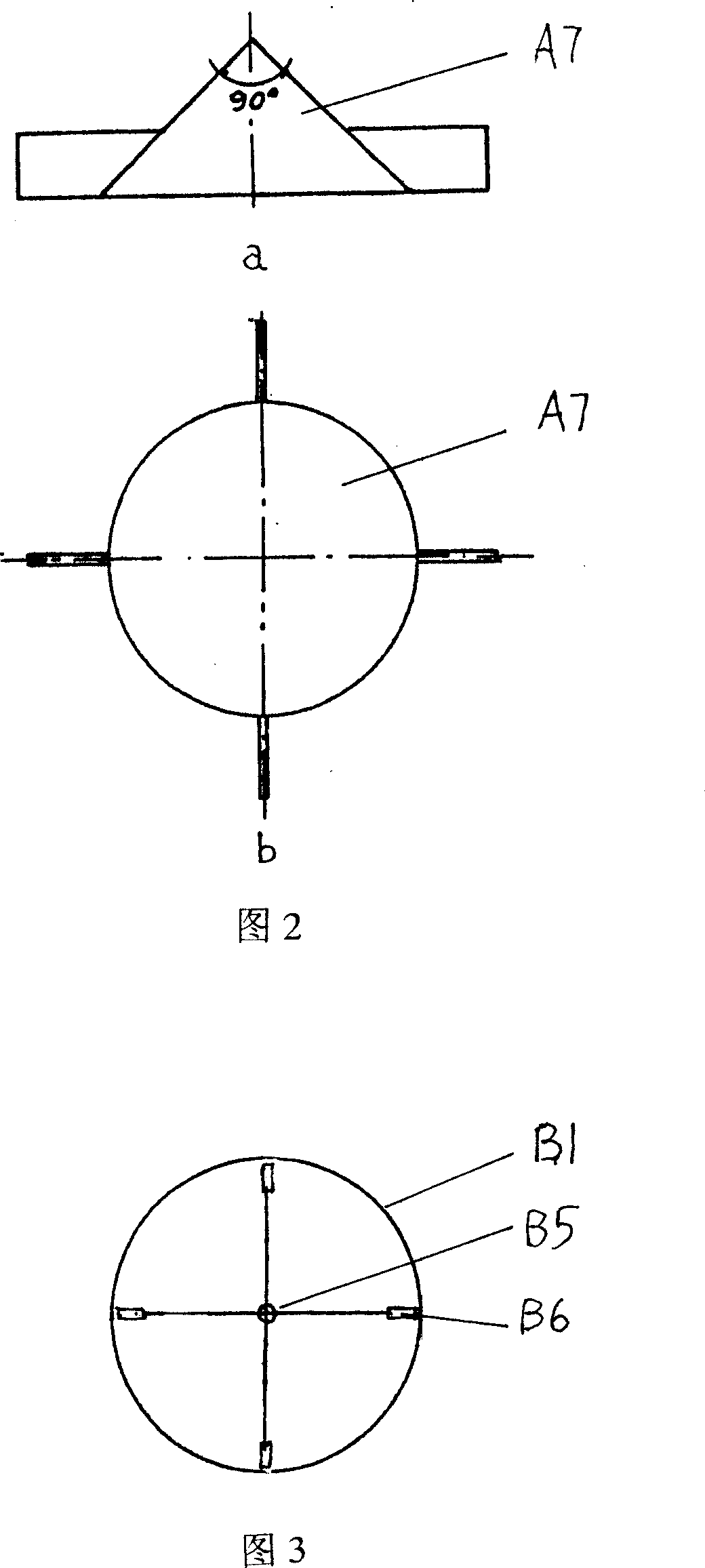

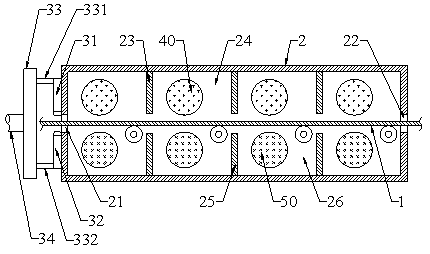

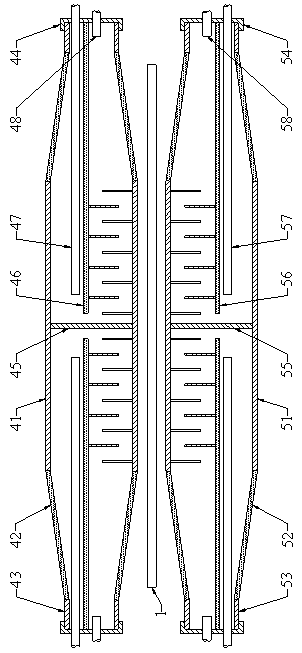

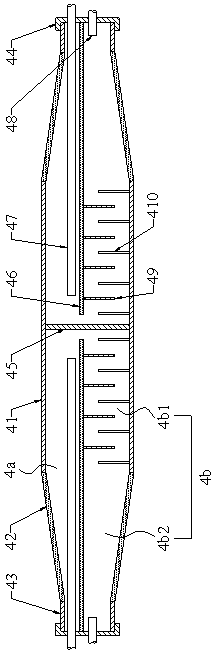

Complete sets for continuous synthesis of phenyl chlorosilane

InactiveCN101007820AHigh synthesis efficiencyExtended service lifeGroup 4/14 element organic compoundsHeat conductingChlorosilane

The invention relates to a kind of complete equipment for continuously preparing phenyl chloro-silicane. It means to provide a kind of complete equipment that is characterized by no use of catalyst, short synthesis route and hihg productivity, and to solve technical problem of on-line collected carbon removal and only one temperature province in reaction device. Said complete equipment is characterized in that: it comprises pre-heating device A, tubular reaction device B and filtering and cleaning device C which are in cascade connection; the upper inlet A2 on pre-heating device is material inlet, the lower outlet A3 is connected thorugh lower inlet on tubular reaction device, the upper outlet of reaction device is connected to the inlet of filtering and cleaning device; and the jacket equipped on said three devices are connected with heat conducting medium.

Owner:HANGZHOU NORMAL UNIVERSITY

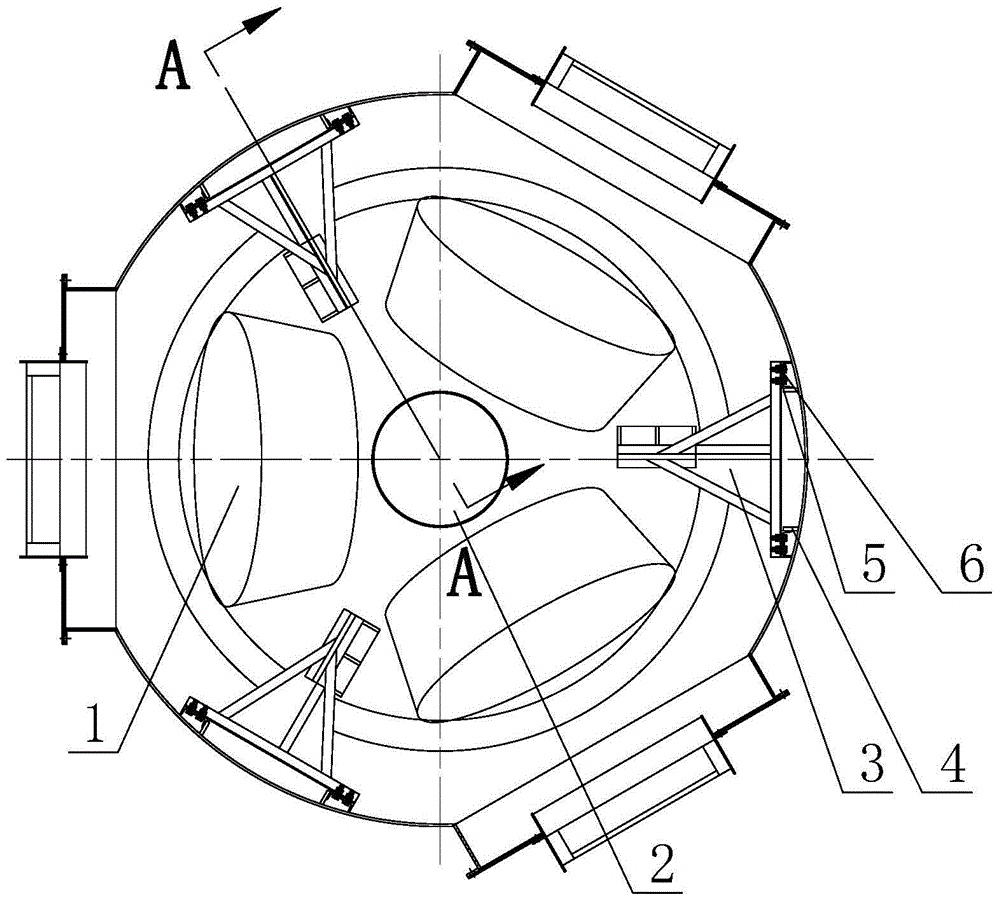

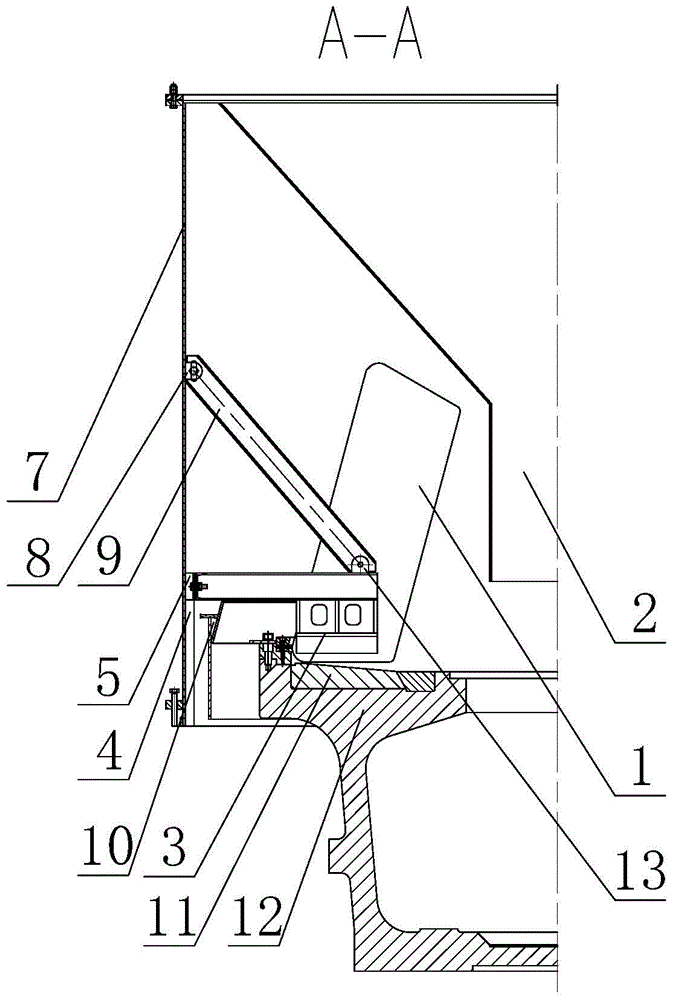

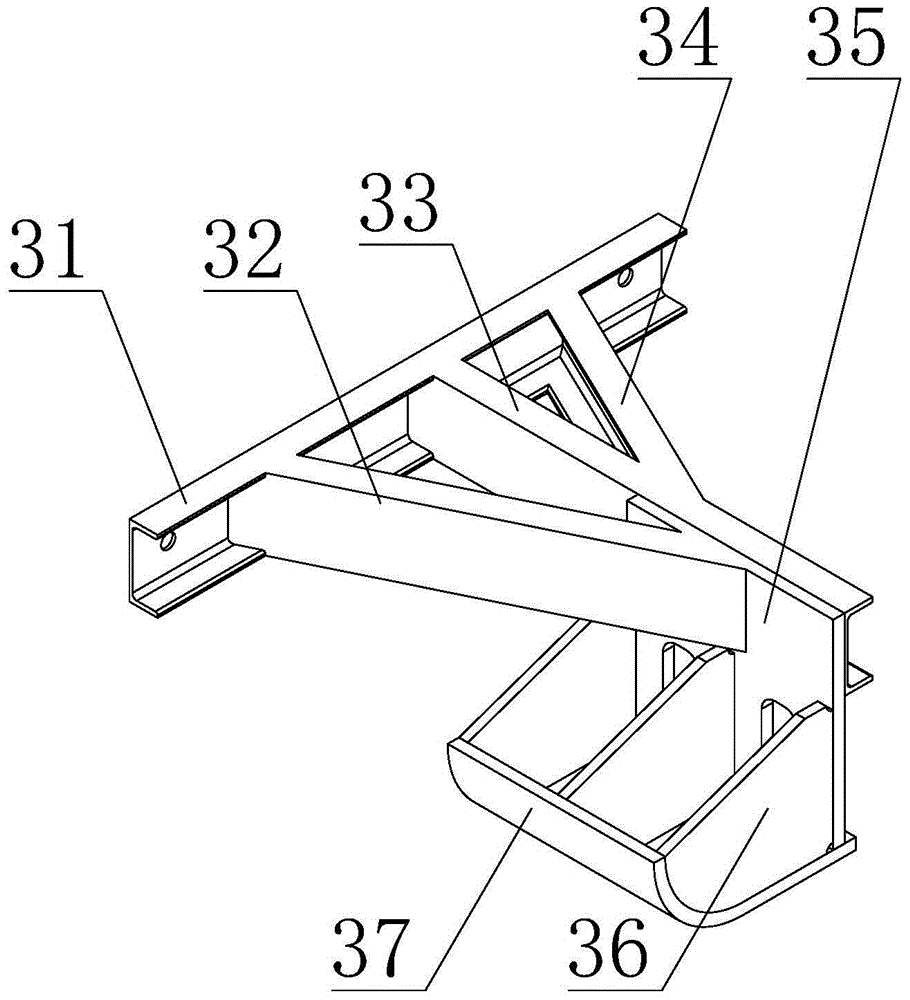

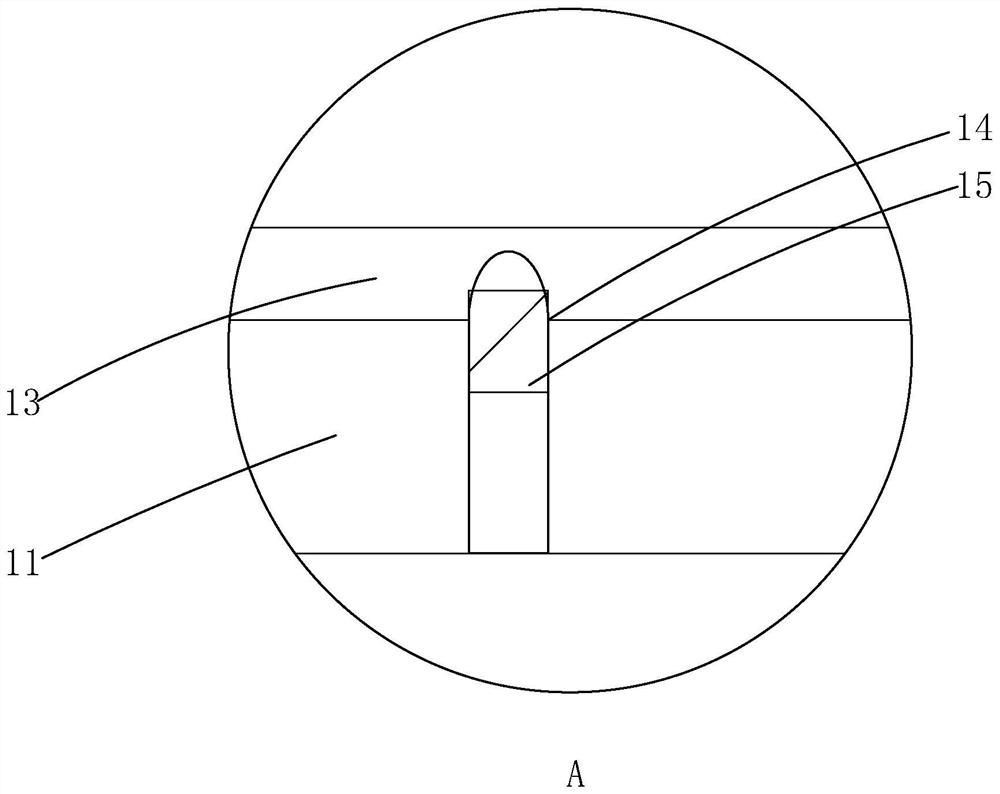

Vertical roll grinder grinding disc material layer stabilizing device and vertical roll grinder

The invention relates to a vertical roll grinder and a vertical roll grinder grinding disc material layer stabilizing device. The vertical roll grinder comprises a grinding disc, a middle shell, grinder rolls and a central feeding articulated chute, and a grinding disc liner plate is installed on the grinding disc; the vertical roll grinder grinding disc material layer stabilizing device comprises supporting plates welded to the middle shell, connecting profile steel with long holes is welded to the supporting plates, material laying frames are installed on the connecting profile steel, the front ends of the material laying frames are provided with arc-shaped material laying plates, and the bottom faces of the arc-shaped material laying plates are perpendicular to the axis of the vertical roll grinder. The vertical roll grinder grinding disc material layer stabilizing device and the vertical roll grinder have the advantages that the thickness of the material layer can be effectively controlled, and the exhausting and pre-bulking effects can be achieved on materials between two main rolls.

Owner:中材(天津)粉体技术装备有限公司 +1

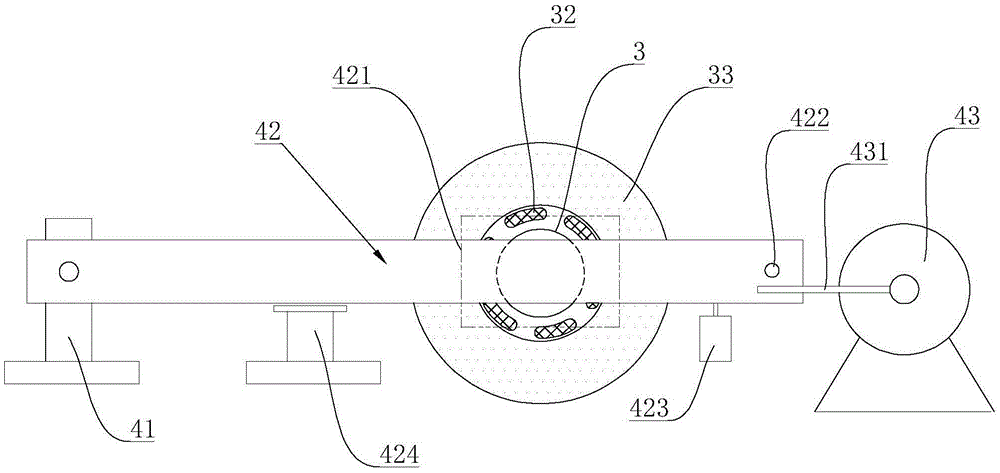

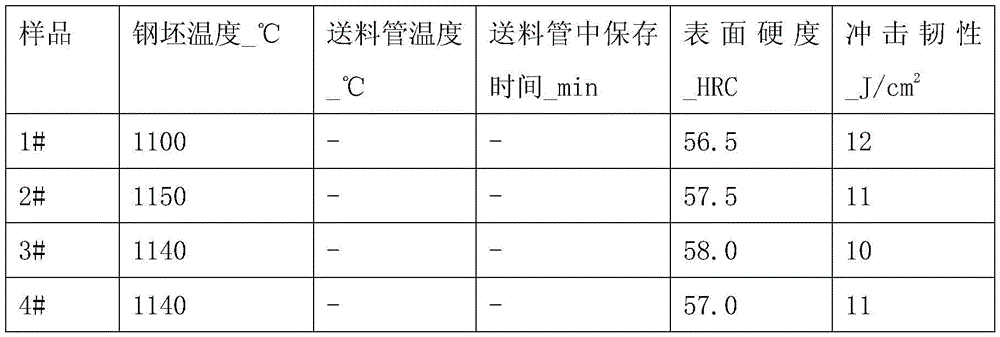

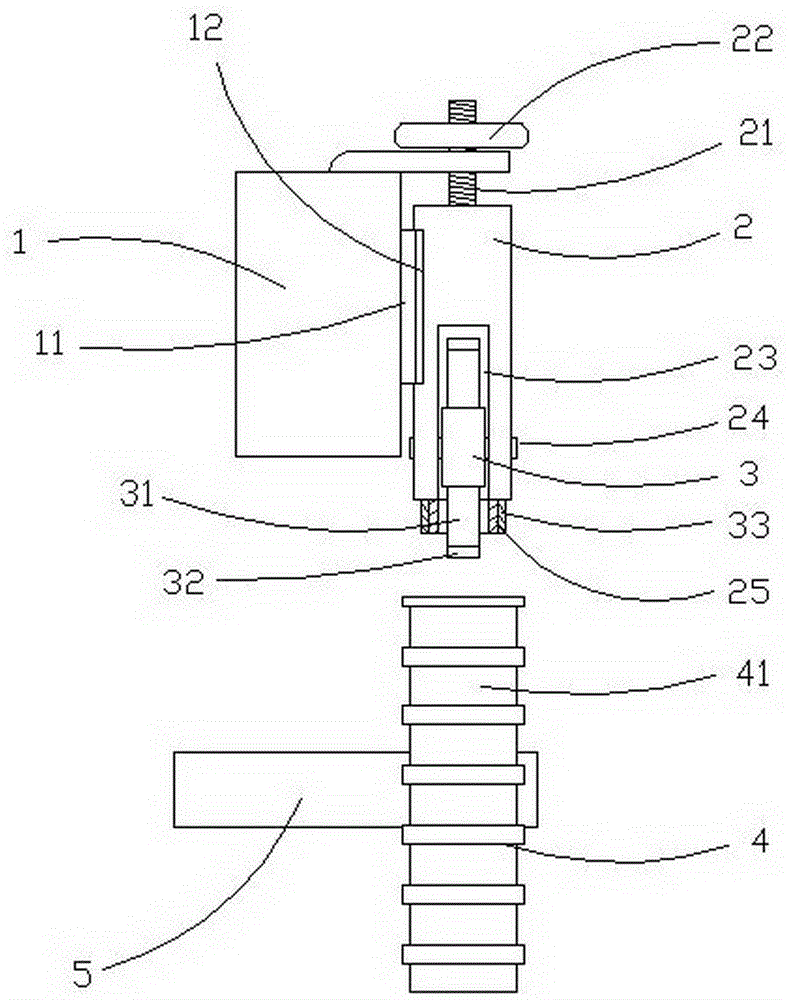

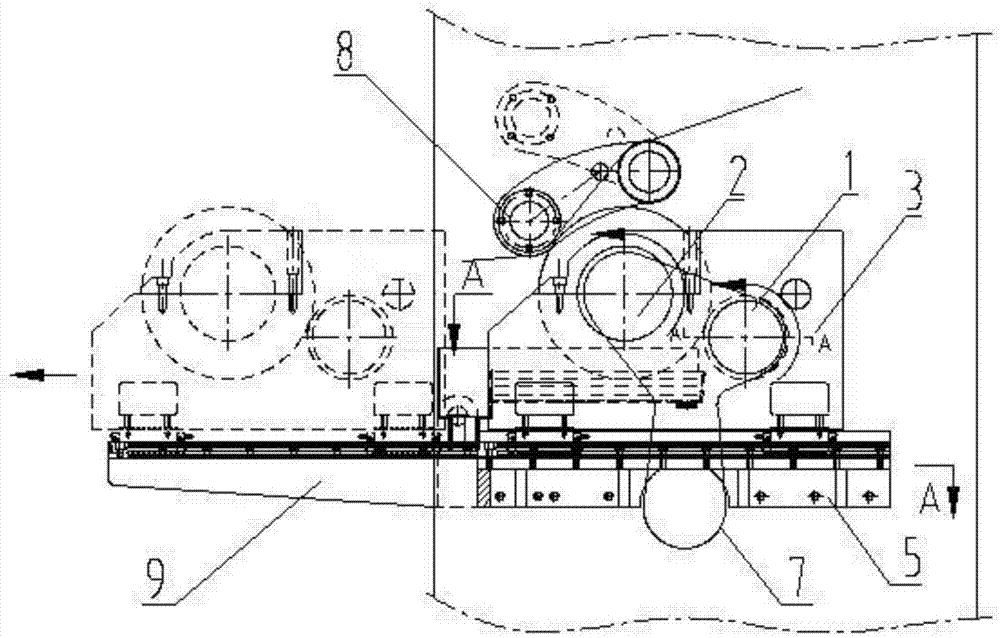

Manufacturing device and manufacturing method of ball mill steel ball

InactiveCN105479102AImprove temperature consistencyImprove performanceMetal-working apparatusFurnace typesSteel ballQuenching

The invention relates to a manufacturing device and a manufacturing method of a ball mill steel ball. The device comprises a forging machine and a quenching device, and further comprises a feeing pipe, wherein the inner part and / or the outer part of the feeding pipe are / is provided with insulating layers / an insulating layer; an inlet of the feeding pipe is connected with a discharge end of the forging machine; an outlet of the feeding pipe is connected with a feeding end of the quenching device; and the inlet of the feeding pipe is positioned above the outlet of the feeding pipe. When the device is adopted for manufacturing the steel ball, during the two procedures of steel ball forging and quenching, the steel ball is subjected to tempering treatment during the high-temperature steel ball transportation process in the feeding pipe; on one hand, the steel ball can be prevented from being influenced by external airflow, and the temperature uniformity before steel ball quenching is improved; and on the other hand, the lattice imperfection and internal stress generated during steel ball forging can be eliminated, after the steel ball is subjected to follow-up quenching, the performance of the steel ball is obviously improved, the product uniformity is good, and the continuous production is not influenced.

Owner:米易华星钒钛科技有限责任公司

Special annealing kiln for producing float glass

ActiveCN108483882ADoes not affect continuous productionNot easy to bendGlass productionTemperature differenceKiln

The invention relates to a special annealing kiln for producing float glass. The special annealing kiln comprises a kiln body, wherein an inlet for the float glass to enter is formed in one side of the kiln body; a plurality of upper heat insulation boards are fixedly arranged inside the kiln body; the upper part of the kiln body is divided into a plurality of upper annealing regions by the upperheat insulation boards; lower heat insulation boards are arranged under the upper heat insulation boards; the lower part of the kiln body is divided into a plurality of lower annealing regions by thelower heat insulation boards; a wind screen mechanism is arranged outside the inlet; an upper cooling mechanism is arranged in each upper annealing region; a lower cooling mechanism is arranged in each lower annealing region. According to the special annealing kiln for producing the float glass, a wind curtain wall is formed by the wind screen mechanism arranged on the outer side of the inlet of the kiln body and is used for stopping external heat from entering the annealing kiln, so that the annealing effect is ensured, the operation is facilitated and the influence on continuous production of the float glass is avoided; by matching the upper cooling mechanisms with the lower cooling mechanisms, temperature difference between the side part and the middle part of the float glass is reduced, and the annealed float glass is not easy to bend.

Owner:TG ANHUI GLASS

Method for producing high purity extractive (methyl) acrylic acid

ActiveCN101219948AImprove removal effectDoes not affect continuous productionOrganic compound preparationCarboxylic compound preparationDistillationThiourea

The invention relates to a method for preparing high-purity fine (methyl) acrylic acid, which adds a composite ethyleneurea consisting of a guanidine compound or the salt or urea or thiourea of the guanidine compound into crude (methyl) acrylic acid to react, then introduces the reaction liquid to a distillation column to carry out intermittent or continuous distillation to obtain a high-purity fine (methyl) acrylic acid product which contains no aldehyde and maleic. The composite ethyleneurea can remove the aldehyde and maleic in the crude (methyl) acrylic acid completely with no solid impurity generating.

Owner:SHANGHAI HUAYI NEW MATERIAL

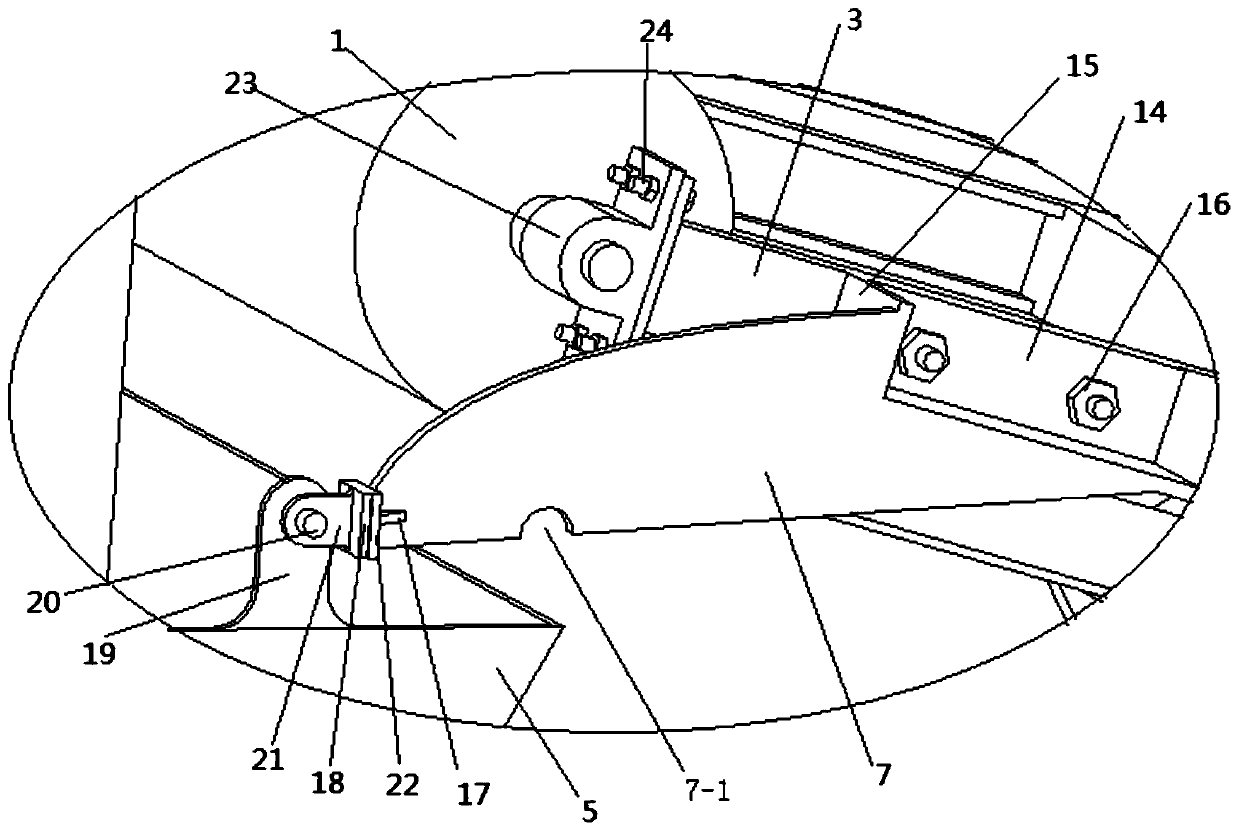

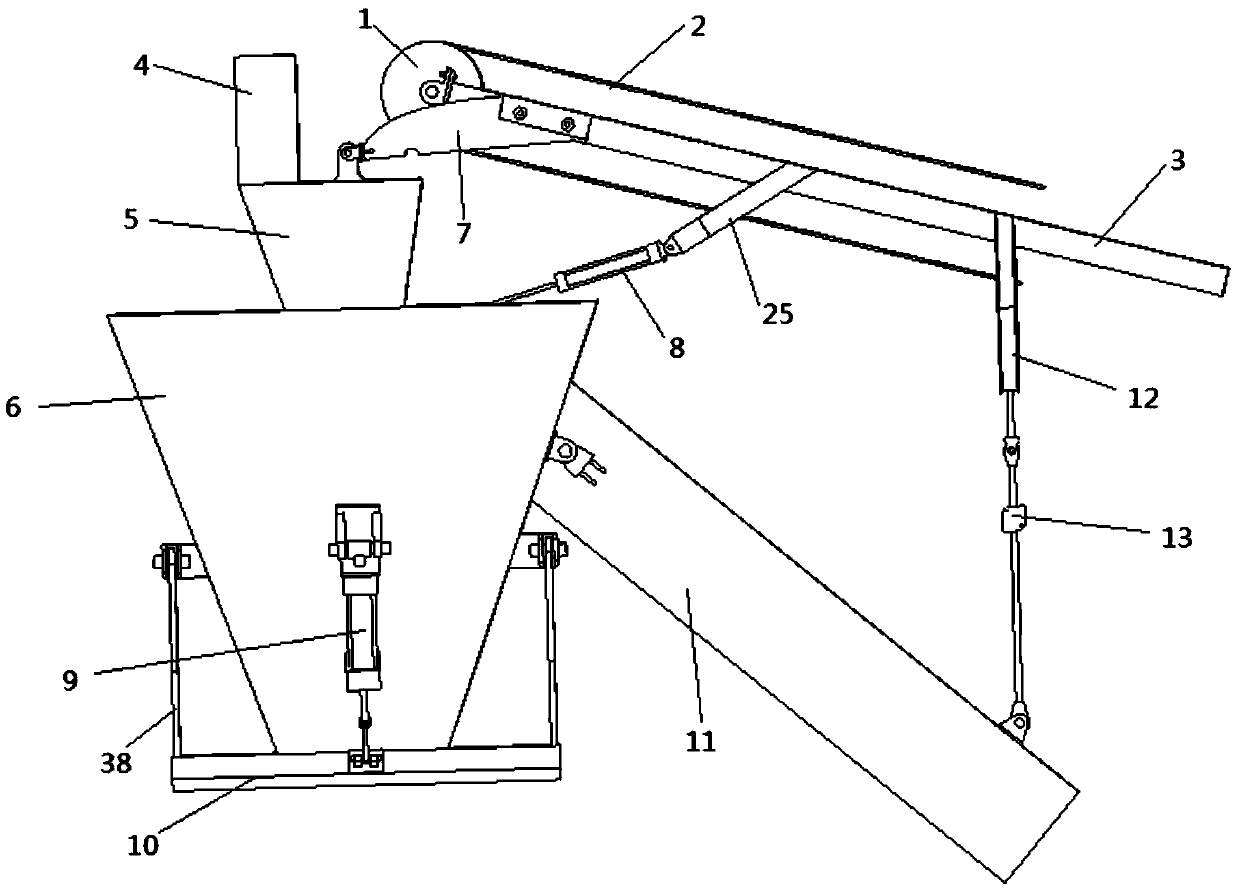

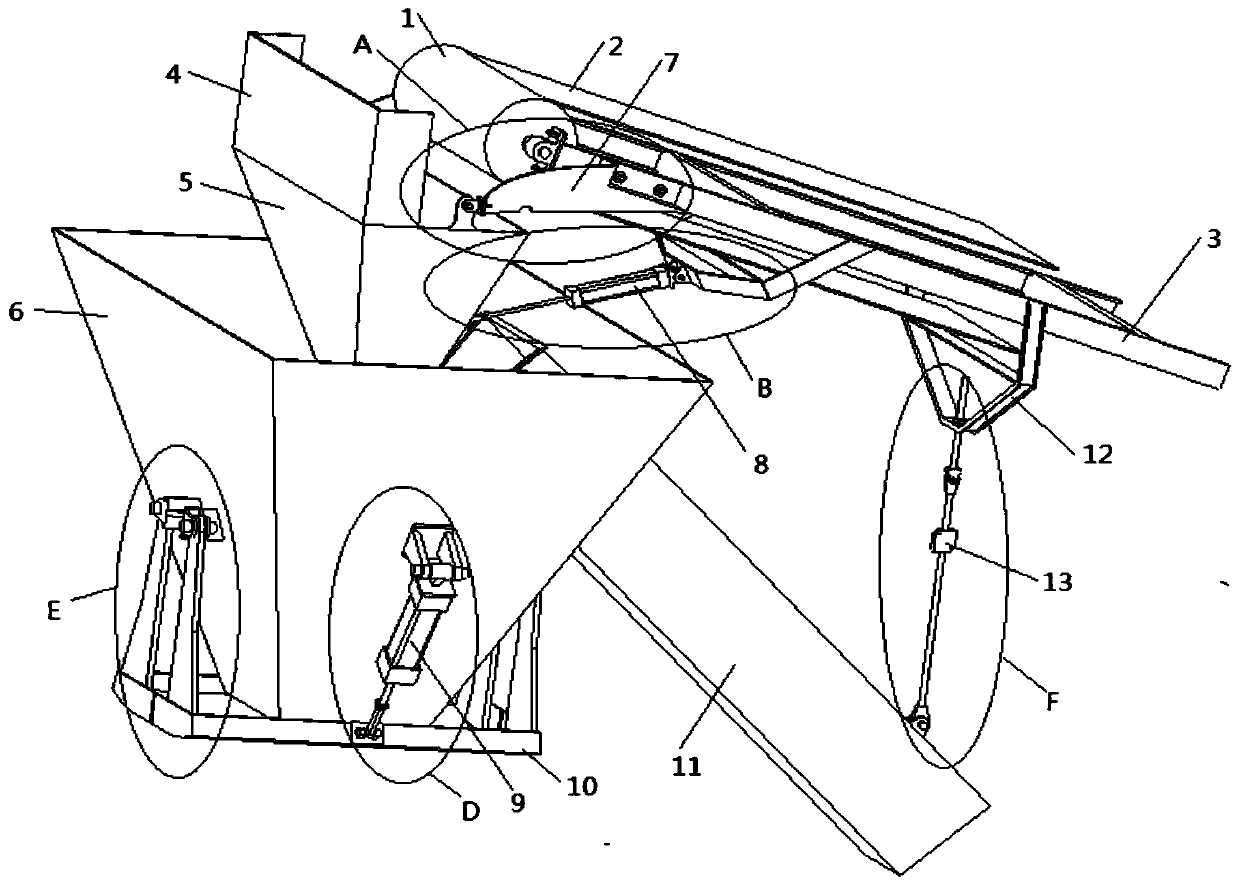

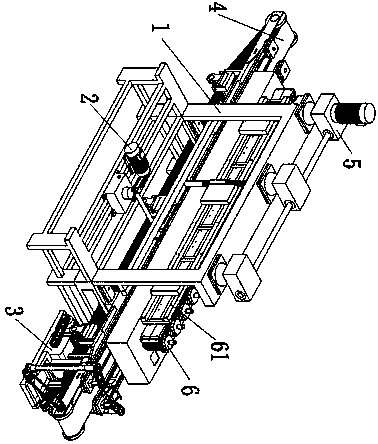

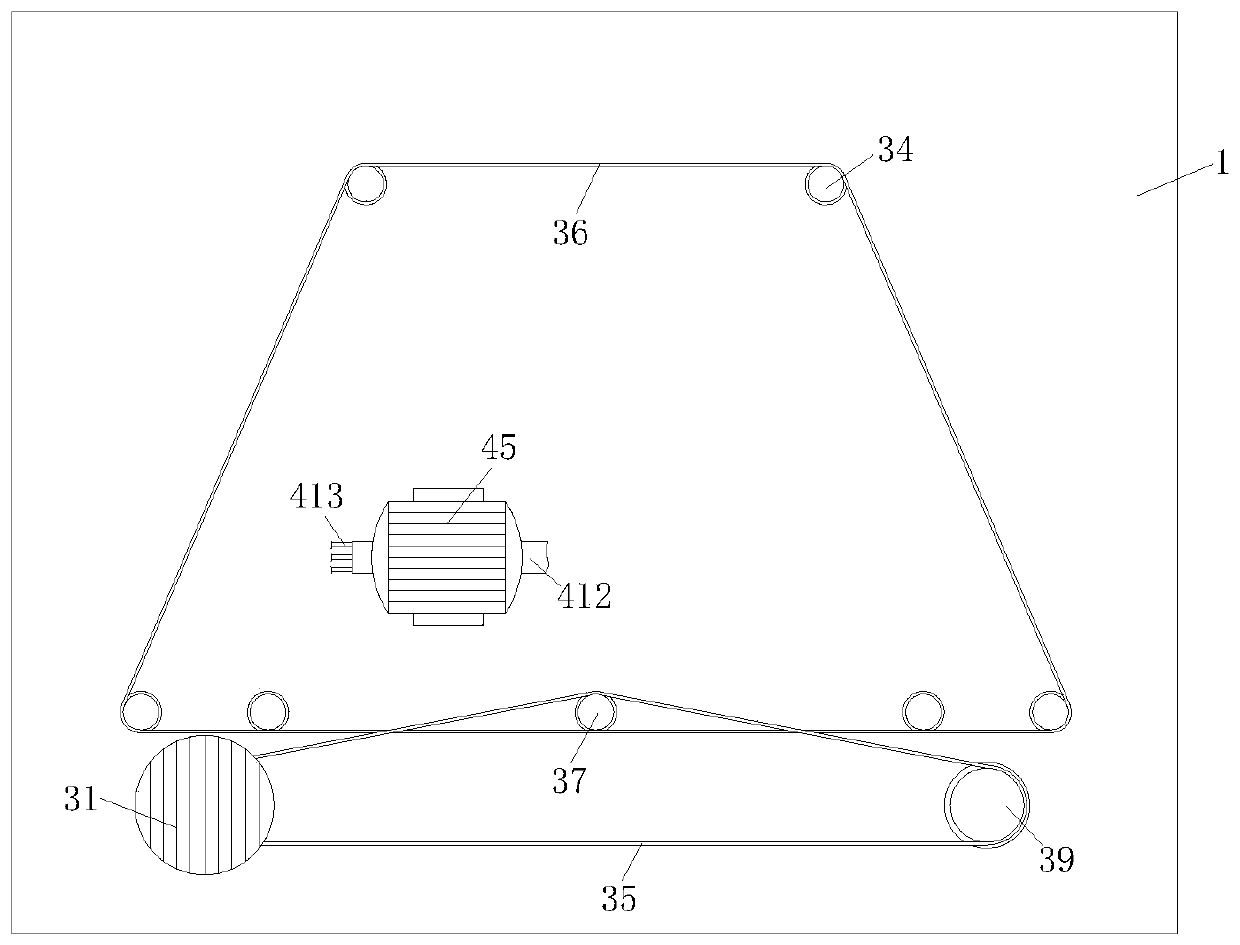

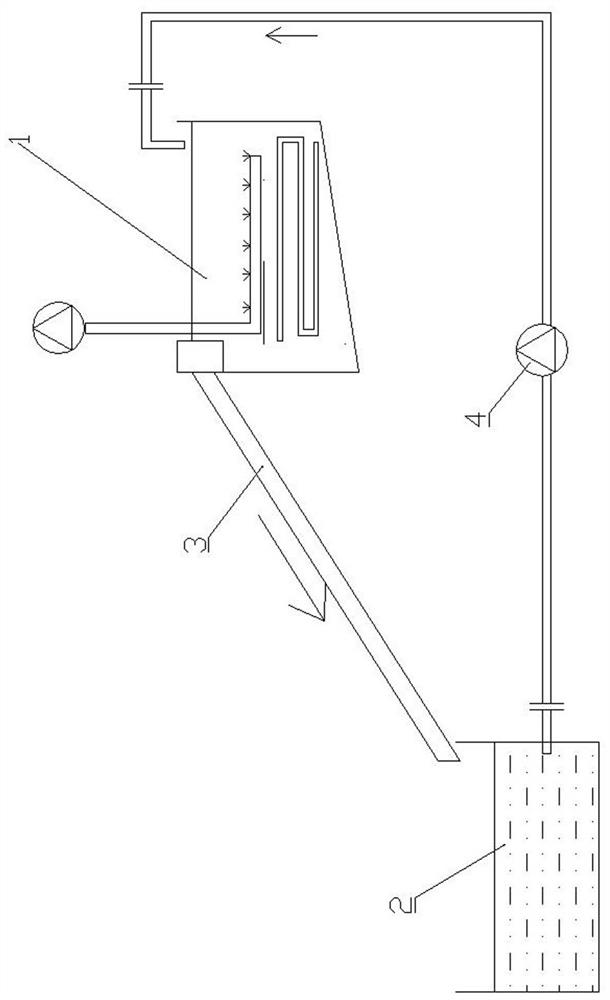

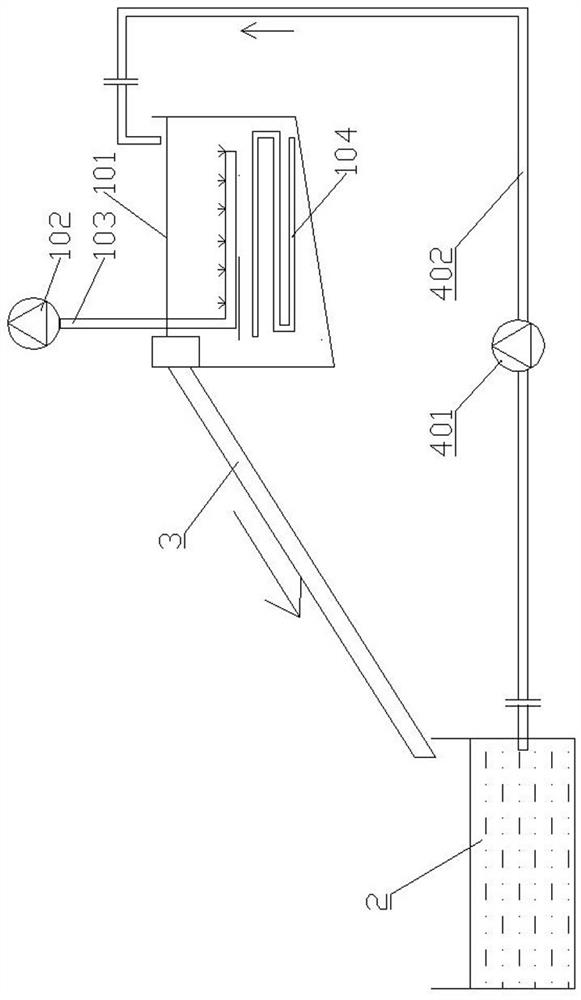

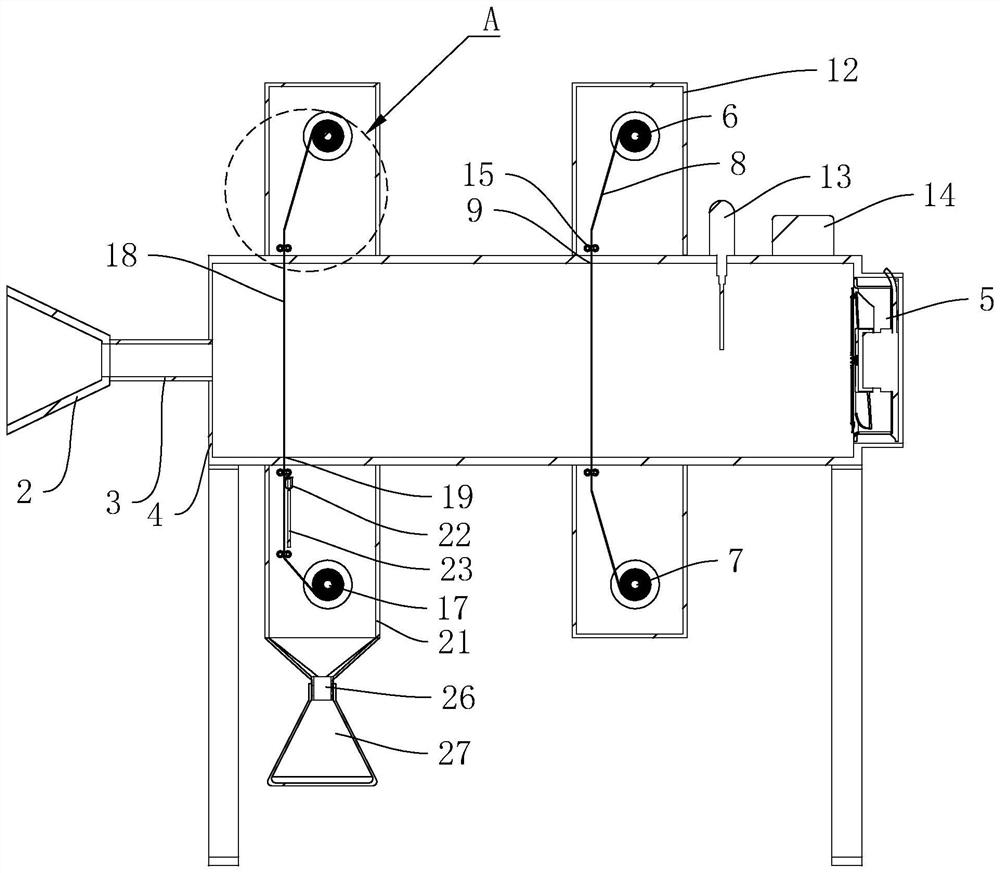

Continuous type mixing station stock bin with online sampling device and sampling method

PendingCN110834967AAvoid unevennessRealize quantitative samplingConveyorsWithdrawing sample devicesGas cylinderControl theory

The invention discloses a continuous type mixing station stock bin with an online sampling device and a sampling method. The continuous type mixing station stock bin comprises a conveyor belt rack, ahanging beam, a guide hopper, a guide tube and a finished product bin, wherein the conveyor belt rack is placed in an inclined mode; the hanging beam is in bolt connection to the conveyor belt rack; the guide hopper is hinged with the hanging beam; a blocking plate is welded on the guide hopper; the lower part of the guide hopper is equipped with the finished product bin; one side of the finishedproduct bin is hinged with the guide tube; and the discharge end of the guide tube is connected to the conveyor belt rack through a weighing scale. The sampling method comprises the following steps: I, clearing zero for a weighing sensor; II, inputting a sampling weight value, namely a preset value; III, automatically sampling by pressing down an enter key, and controlling a pulling hopper gas cylinder to push back the guide hopper while accumulated flow achieves the preset value, thereby accomplishing sampling. The continuous type mixing station stock bin is simple in structure, is convenientand quick in sampling, and can realize online automatic sampling.

Owner:CHANGAN UNIV

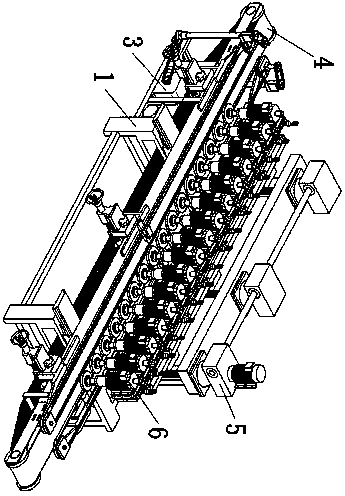

Glass plane grinding and polishing machine capable of achieving automatic transportation and deviation prevention

PendingCN107914207AAvoid quality problemsGood orientationGrinding machinesGrinding feedersAutomatic transmissionEngineering

The invention relates to a glass plane grinding and polishing machine capable of achieving automatic transportation and deviation prevention. The glass plane grinding and polishing machine comprises arack, a swinging mechanism, a power transmission mechanism, a transportation mechanism, a lifting mechanism and a grinding and polishing mechanism, wherein the swinging mechanism is mounted on one side of a rack platform; the other side of the rack platform is connected with the transportation mechanism through an orbit; one side of the transportation mechanism is connected with the swinging mechanism through a connecting rod; a power transmission group is arranged at one end of the transportation mechanism; the lifting mechanism is mounted at the top end of the rack; and the grinding and polishing mechanism is connected to a screw of the lifting mechanism. According to the glass plane grinding and polishing machine capable of achieving automatic transportation and deviation prevention,an assembly line working mode is adopted, a plurality of polishing groups arranged in the machine are mutually independent, up-down displacement of each polishing group can be independently adjusted automatically or manually, the continuous production requirement of a production line is met, production efficiency is improved, and polishing quality and the polishing effect of polished surfaces of crystal ornaments are greatly improved.

Owner:张世鹏

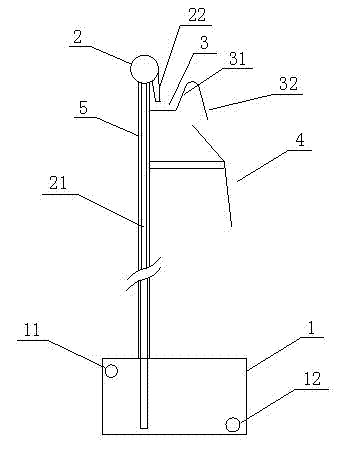

Dedusting and humidifying device

InactiveCN102764551AReduce cleaning frequencyReduce workloadUsing liquid separation agentWater flowEngineering

The invention provides a dedusting and humidifying device to solve the problems that dust and fine particles of a cleaning chamber can not be taken away after an automobile body is cleaned and the automobile body is polluted. The dedusting and humidifying device disclosed by the invention comprises a water tank, a water pump and a water overflow groove, wherein the water pump is respectively communicated with the water tank and the water overflow groove so as to pump water in the water tank into the water overflow groove; and the water overflow groove is fixed above the water tank by a bracket, so that water overflowing from the water overflow groove flows back to the water tank, and the length of the water tank is greater than that of the water overflow groove. When being used, the dedusting and humidifying device is arranged in the cleaning chamber, a water curtain flowing from the water overflow groove to the water tank is formed by the water pump and the water overflow groove, the surrounding dry dust and fine particles can be humidified in the flowing process of the water curtain, and are sunken on the ground, and a part of the dust and fine particles attach to the water curtain and finally flow back to the water tank together with the water to form circulation, so that the purposes of eliminating static electricity and dedusting are achieved.

Owner:CHERY AUTOMOBILE CO LTD

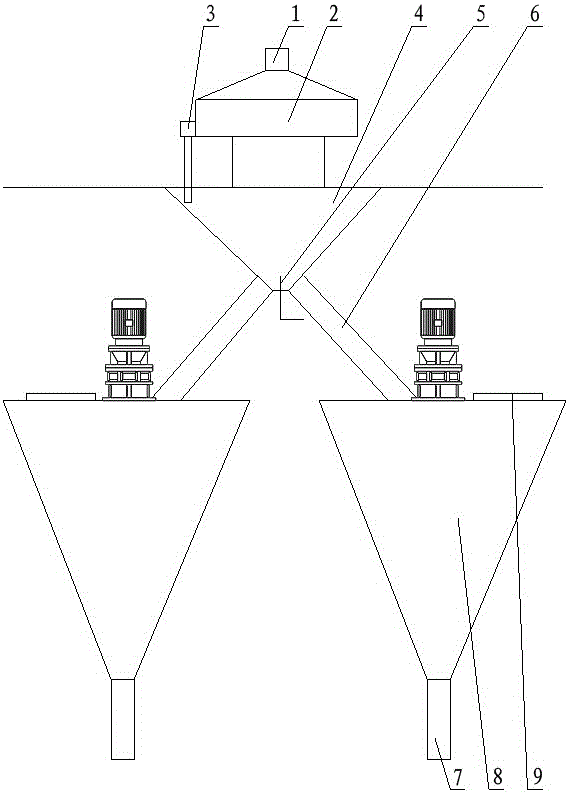

Modified starch product mixing and stirring system

InactiveCN106362633AQuality improvementDoes not affect continuous productionTransportation and packagingMixer accessoriesPulp and paper industryProduct mix

The invention provides a modified starch product mixing and stirring system which comprises a collecting hopper, a dividing switch, at least two paths of dividing pipelines and conical stirrers with the number equal to that of the dividing pipelines. The dividing pipelines are connected to the lower end of the collecting hopper and led to the corresponding conical stirrers respectively, opening and closing of the dividing pipelines are controlled through the dividing switch at the lower end of the collecting hopper, a feeding port is formed in the top of each conical stirrer, and a discharging port is formed in the bottom of each conical stirrer. By means of the modified starch product mixing and stirring system, when the product production qualities are different, products with different qualities can be mixed to be uniform and then delivered, and it can be guaranteed that the products in the same batch are stable in quality and continuous production of subsequent products is not influenced. In addition, stable-quality modified starch in different varieties can be produced, wherein auxiliary materials need to be added into the finished product procedure.

Owner:GUANGXI UNIV

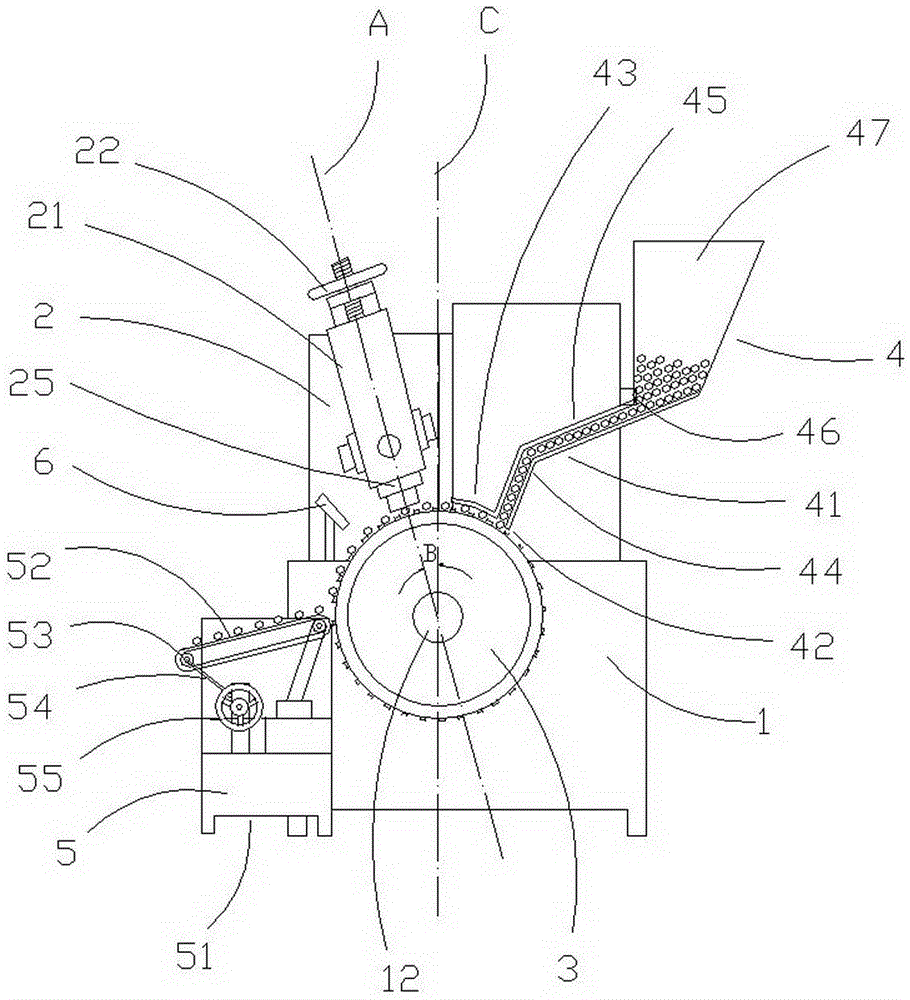

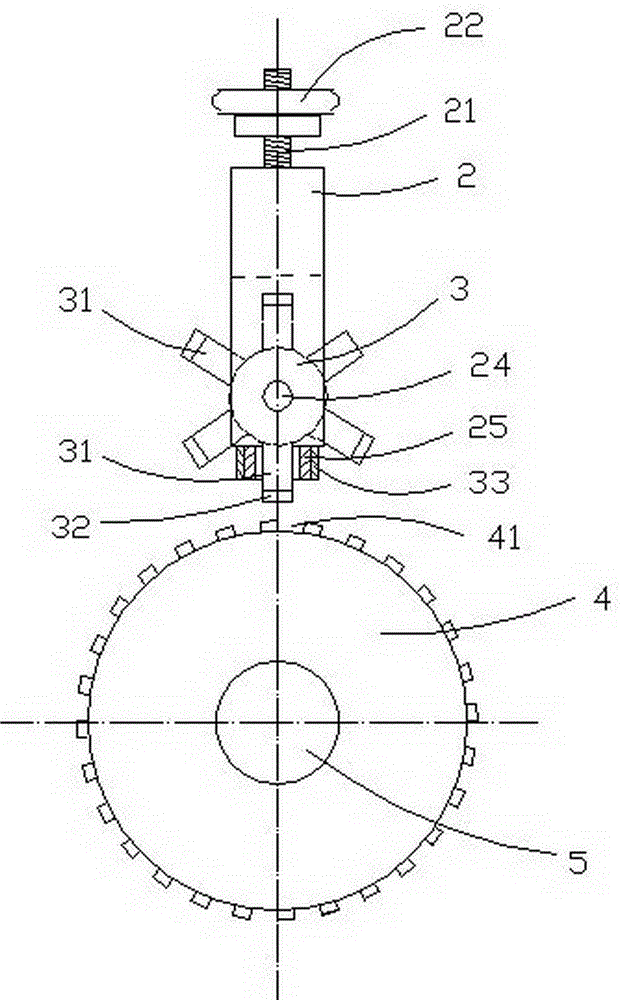

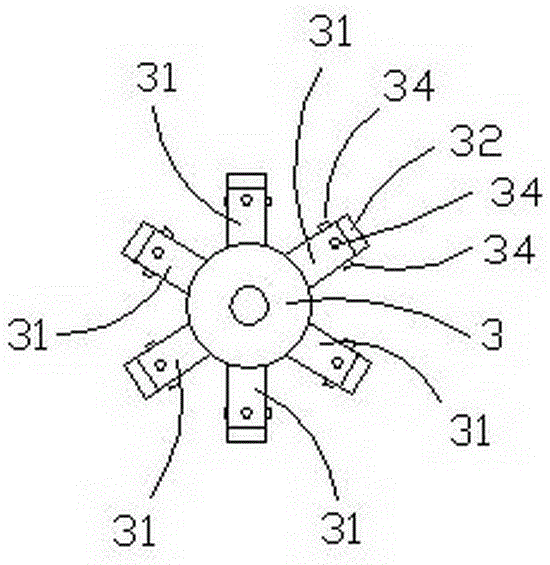

Multi-head automatic printing machine

ActiveCN105584234ADoes not affect continuous productionFast productionStampingEngineeringDrive shaft

The invention discloses a multi-head automatic printing machine. A main shaft is installed in a main shaft box in a machine frame of the printing machine in an inclined mode, the included angle between the main shaft and the plane of a machine body is 30 degrees, a feeding rotation plate is connected to the main shaft in a tipping mode, and locating guide columns on the outer side of the feeding rotation plate are connected to threaded sleeves on a supporting ring in a sleeved mode; a supporting column of a printing mechanism is fixed in a guide rail of a base plate through a pressing plate and a bolt, a screw on the top of the supporting column is provided with an adjusting hand wheel, and a cross-shaped die head is loosely connected in an open groove in the lower end of the supporting column and is provided with four unit matrix control parts containing matrixes; an arc-shaped baffle covering a rolling groove in a suspended mode is arranged at an outlet end of a feeding rack of an inputting mechanism, an arc-shaped stop frame is arranged on the back of a bent material way, and a feed divider is arranged at the lower end port of a hopper; an inclined feeding belt is arranged at the upper part of a support base of an outputting mechanism, the two branch ends of a driven shaft at the other end of the feeding belt are connected with poke rods, and the hand wheel adjusts ascent or descent of the feeding belt.

Owner:ZHENYI ELECTRONICS SHENZHEN

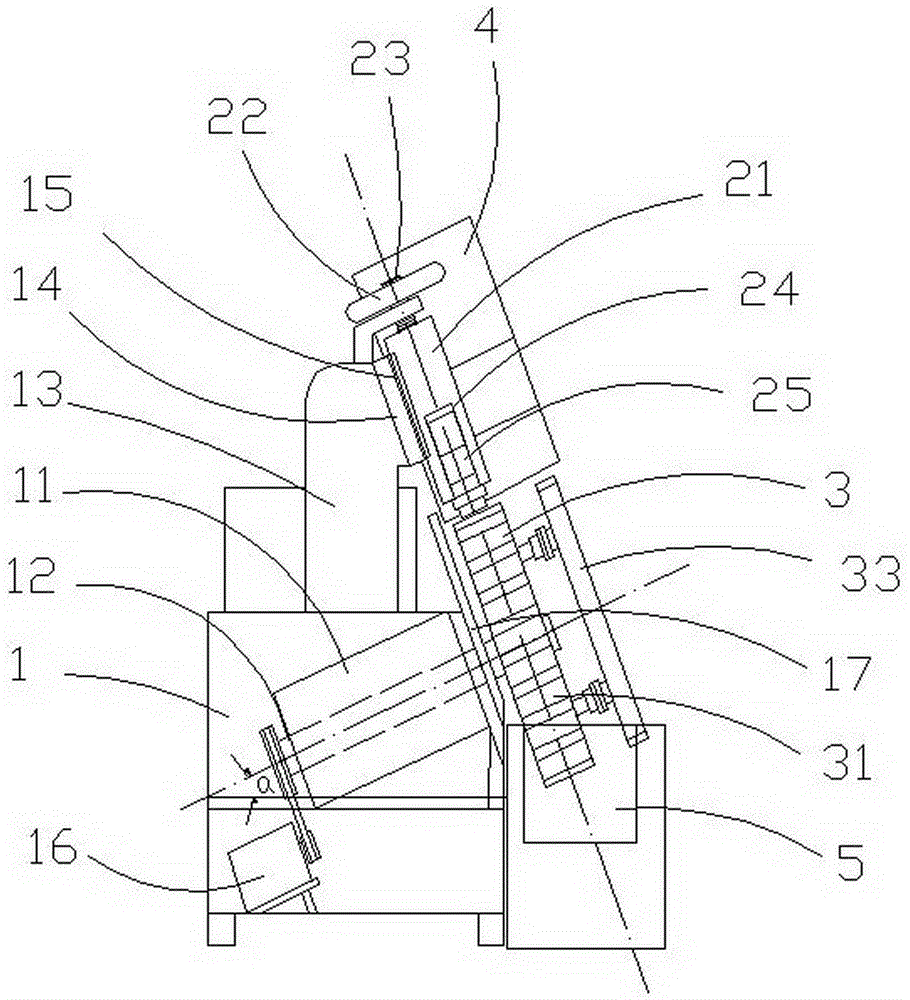

Multi-head character die

ActiveCN105584236ADoes not affect continuous productionFast productionStampingScrew threadManufacturing line

The invention discloses a multi-head character die. The multi-head character die comprises a support, a supporting column and a die head. The support is provided with a longitudinal seat plate. The supporting column is fixed in a guide rail of the seat plate via the support and through a pressing plate and a bolt. The top of the supporting column is connected with a screw. The screw is connected with a hand wheel. An opening groove is formed in the lower end of the supporting column. The die head is embedded and connected in the opening groove through a shaft pin. The die head is provided with 2-6 character die controls connected with character die bodies. Locking devices are arranged at the inner ends of the character die controls and threaded connecting parts of the supporting column. The die head and the supporting column are axially fixed through the locking devices so that the unit character die controls can work. The supporting column is suspended above a rolling disc distributing workpieces. The character die bodies of the character die controls correspond to rolling grooves of the rolling disc. According to the multi-head character die, the character die conversion speed is high, the continuous production of a production line is not affected, and the production efficiency is improved.

Owner:滁州一银丰新材料有限公司

Self-cleaning battery manufacturing equipment

ActiveCN111001596AComprehensive cleaningSmall locationElectrostatic cleaningCleaning using toolsElectrical batteryCell fabrication

The invention provides self-cleaning type battery manufacturing equipment. The equipment comprises a support plate for supporting the equipment, a strip-shaped conveyed pole piece foil material, welding equipment for welding a current collector on the pole piece foil material, and a roller shaft self-cleaning mechanism for automatically cleaning each conveying roller shaft for conveying the polepiece foil material, and relates to the field of battery manufacturing. According to the self-cleaning type battery manufacturing equipment, a special roller shaft transmission mode for transmitting the pole piece foil material is arranged so that roller shaft cleaning is automatically performed along with production and transmission. Dust on the pole piece foil material can be synchronously cleaned in a semi-closed manner. The pole piece foil material and the roller shaft are cleaned in a complementary manner. Therefore, problems that the roller shaft and the pole piece foil material are easily contaminated by dust, the dust on the roller shaft and the dust on the pole piece foil material are difficult to clean synchronously, the roller shaft and the pole piece foil material often interfere with each other and a trade-off state is generated, a welding effect is directly influenced by the dust, and quality of a finished product is influenced when a common battery is manufactured and processed by a sheet making machine are effectively solved.

Owner:齐河智谷产业发展有限公司

Device for controlling Fe < 2 + > concentration in phosphating solution

PendingCN112064002AReduce Fe2+ concentrationGuaranteed stabilityMetallic material coating processesChemistryEngineering

The invention discloses a device for controlling Fe < 2 + > concentration of a phosphating solution. The device comprises an oxidation reaction device, a phosphating tank body, an overflow pipe and awater pumping device, and the oxidation reaction device is used for removing Fe < 2 + > in the oxidized phosphating solution. The oxidized phosphating solution flows into the phosphating tank body through the overflow pipe, and the phosphating solution containing Fe < 2 + > in the phosphating tank body flows into the oxidation reaction device through the water pumping device; the phosphating solution containing Fe < 2 + > in the phosphating tank body is introduced into the oxidation reaction device to complete the reaction, so that the continuous production of the phosphating process is not influenced; and phosphated residues generated in the removal process are also remained in the oxidation reaction device, so that the quality problem caused by the phosphated residues is avoided.

Owner:DONGFENG MOTOR FASTENER CO LTD

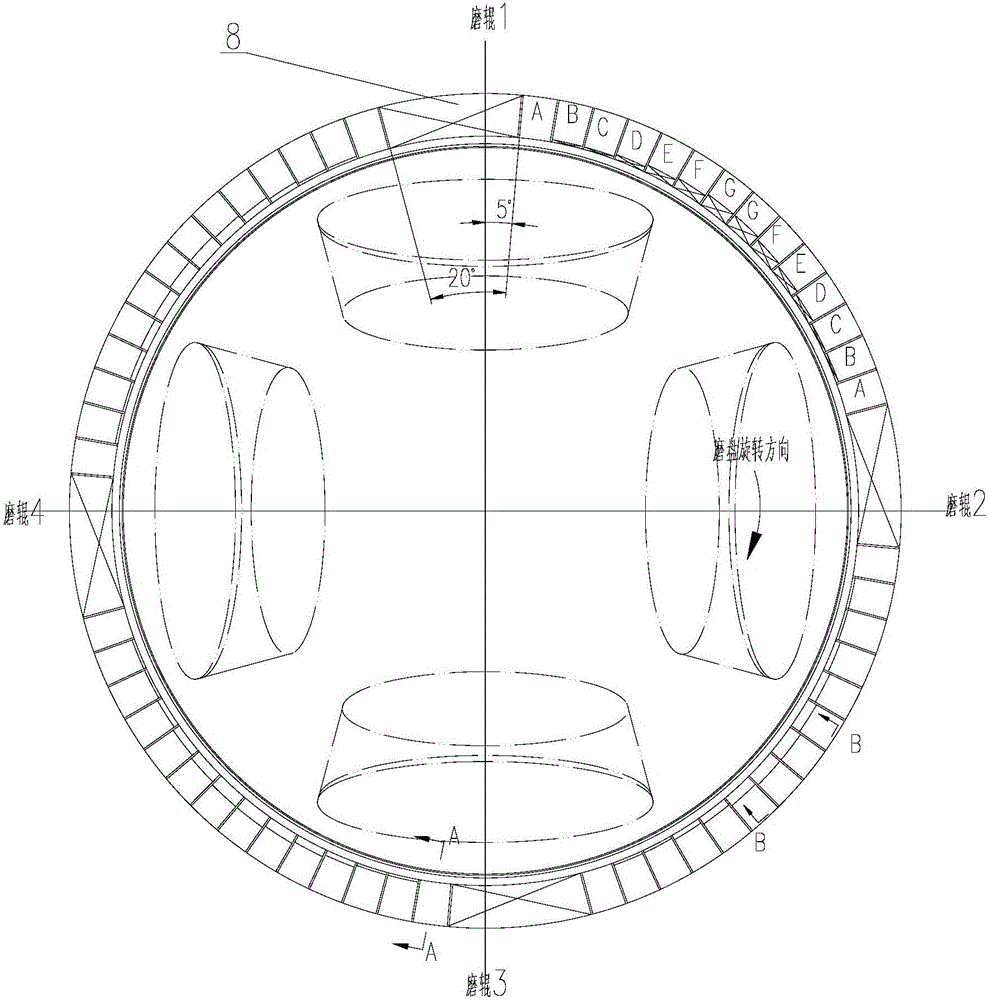

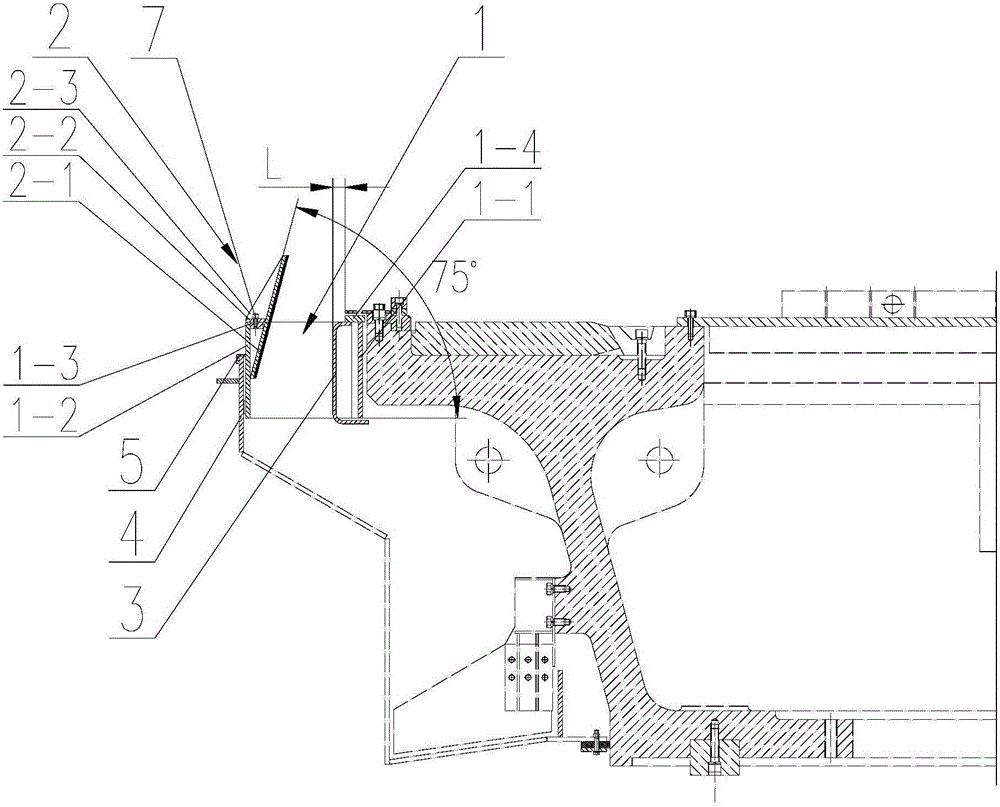

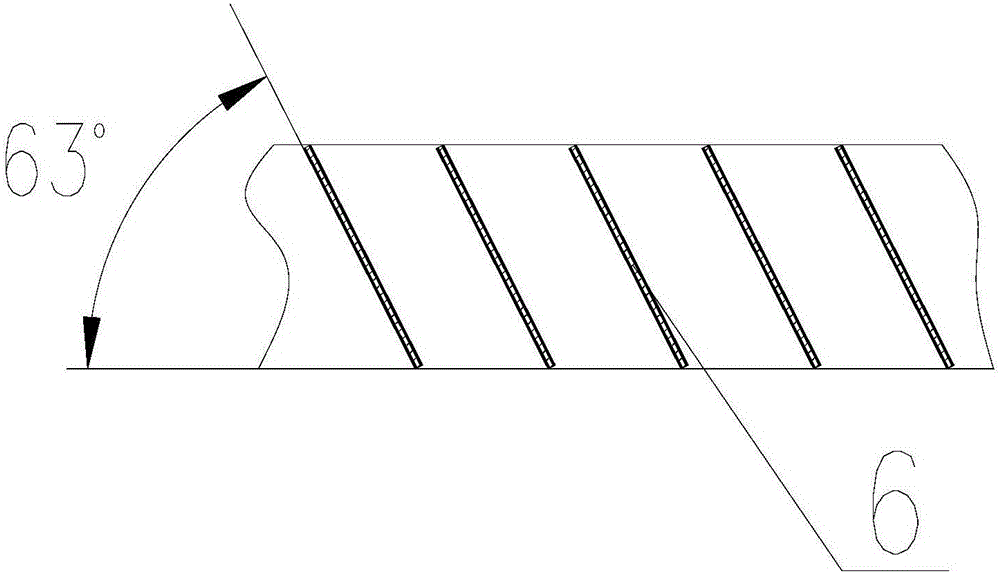

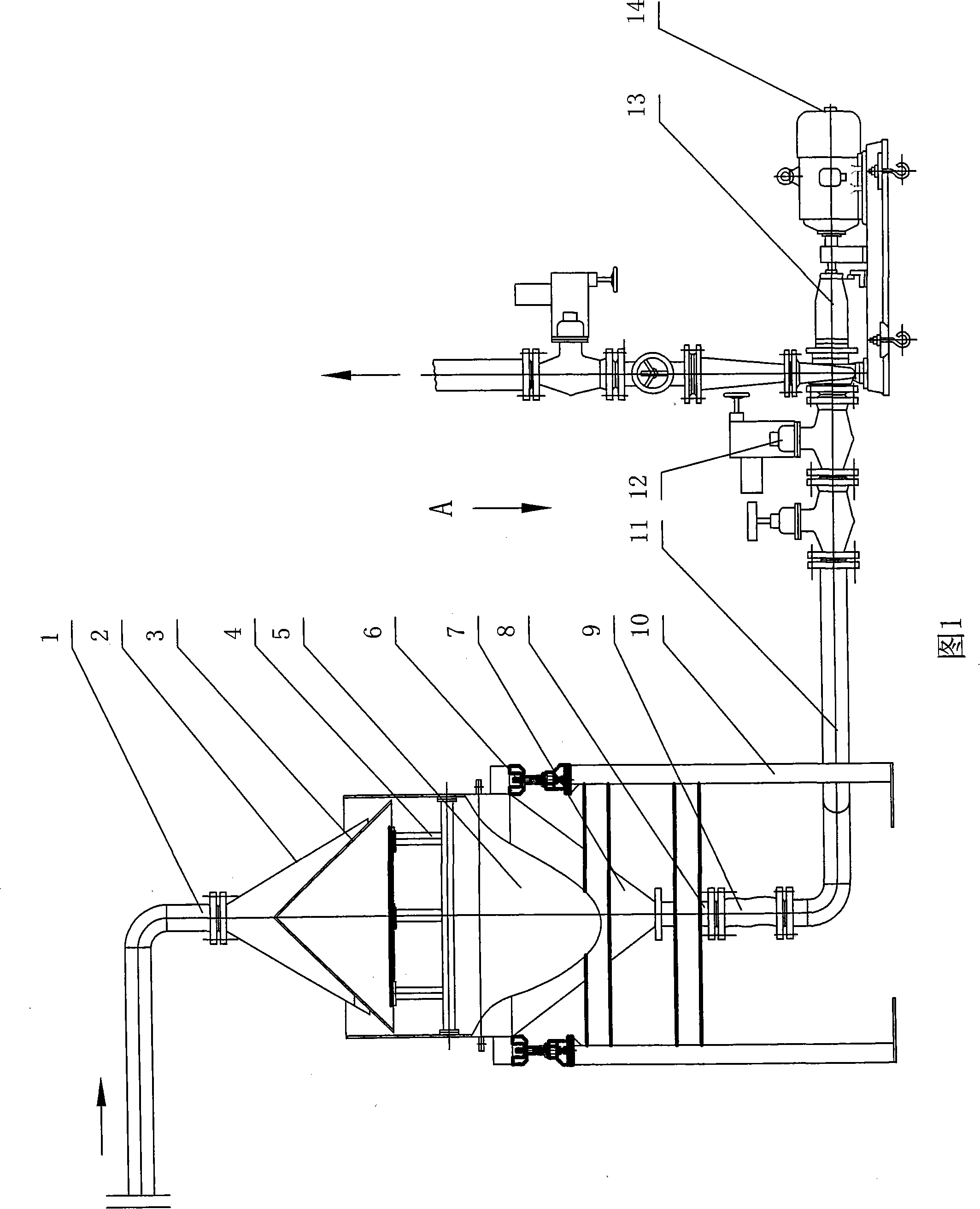

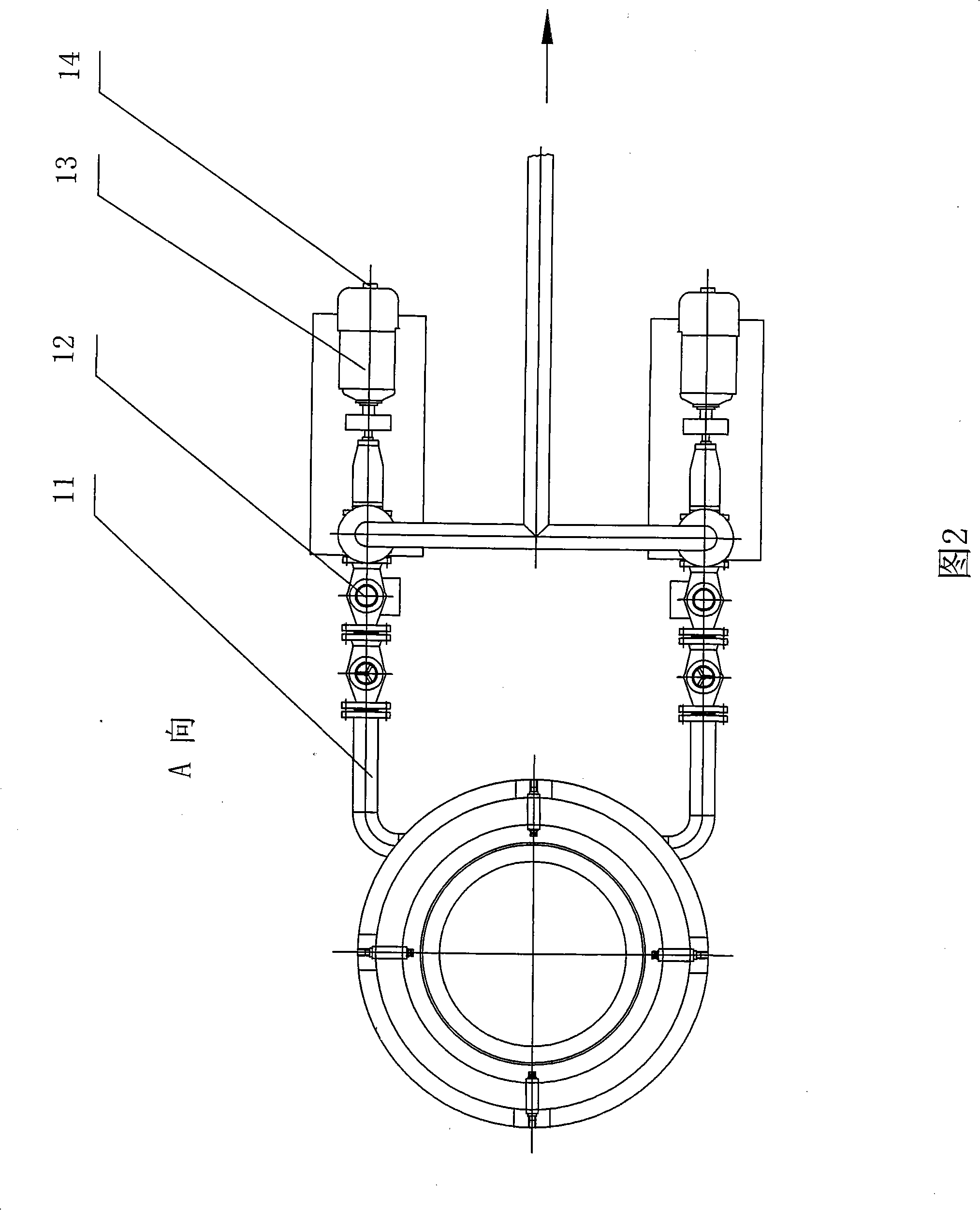

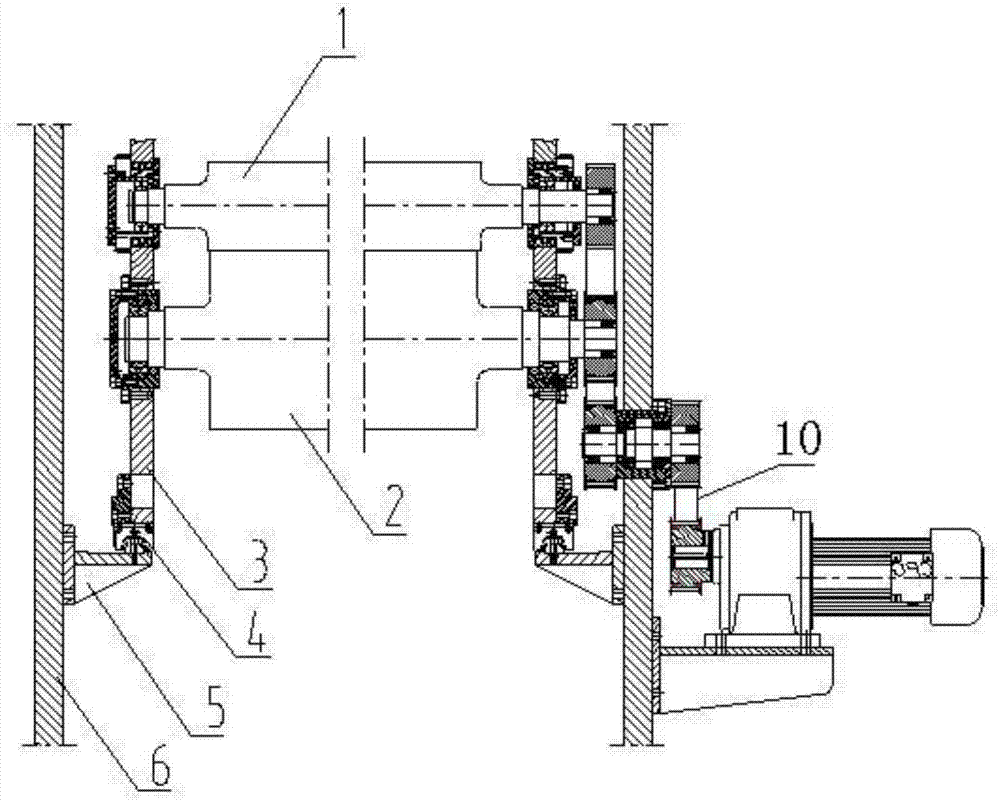

Vertical roller mill air guide ring device

The invention relates to a vertical roller mill air guide ring device, which comprises an air ring, an air guide ring, an air adjusting plate and an air flue, wherein the air ring is fixedly arranged at the upper part of the air flue through an L-shaped suspension plate; the air ring comprises an inner side annular plate, an outer side annular plate and a shutter guide plate; the shutter guide plate is located between the inner side annular plate and the outer side annular plate; an included angle of 63 degrees is formed between the shutter guide plate and the horizontal direction; the air guide ring is arranged on the outer side annular plate through a fastener and inclines by 75 degrees towards the center of a roller mill; and the air guide ring comprises an air guide plate, a connection plate and a reinforcing rib plate. By dopting the technical scheme, the ventilation area of the air ring is easily adjusted when different materials are ground; and the balance of the material amount in the mill and a gas in the mill is ensured, so that a stable material inner cycle number is formed in the mill. Meanwhile, the extension length of the air adjusting plate can be quickly adjusted at the air speed of the actual working condition of grinding different materials, and continuous production is not affected by exchange of the air adjusting plate and the air guide plate after the air adjusting plate is abraded, so that a pressure difference in the vertical mill is reduced; and the requirements of stable production and energy consumption reduction are met.

Owner:中材(天津)粉体技术装备有限公司 +1

Mineral slurry flux on-line detecting device and multi-parameter on-line detecting integrated system

InactiveCN101251395BAccurate measurementRealize detectionVolume/mass flow measurementMaterial analysis by electric/magnetic meansLiquid productAutomatic control

Owner:罗放明

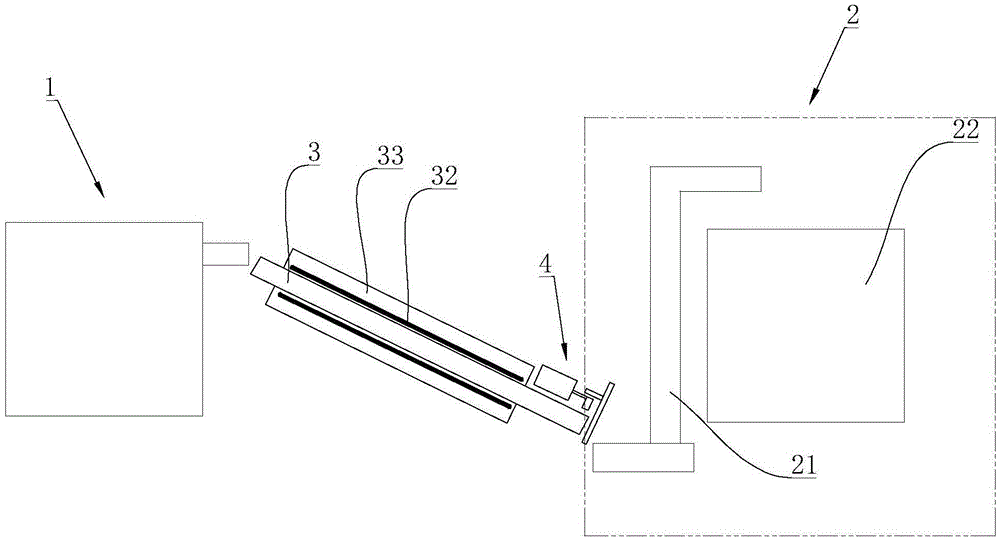

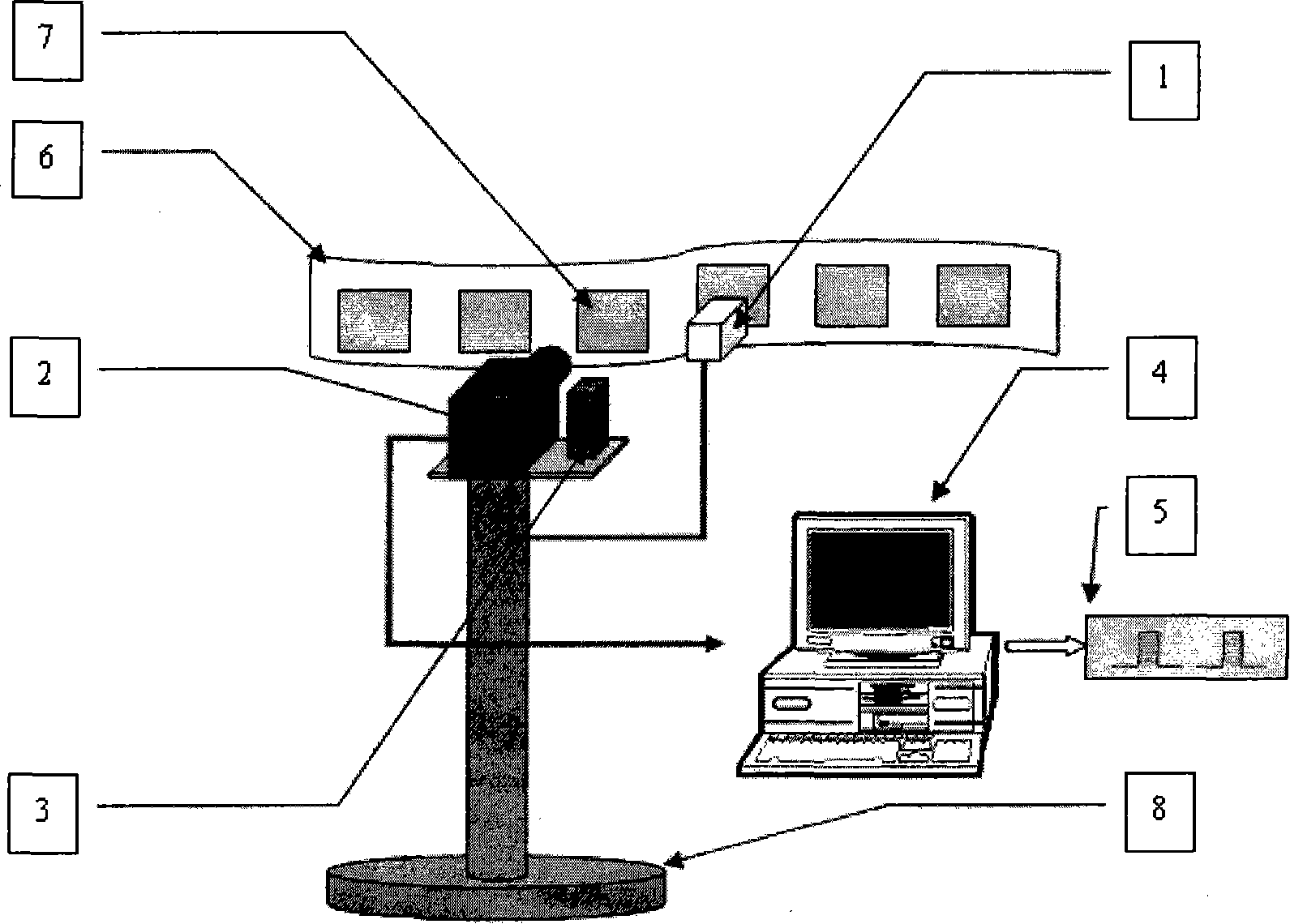

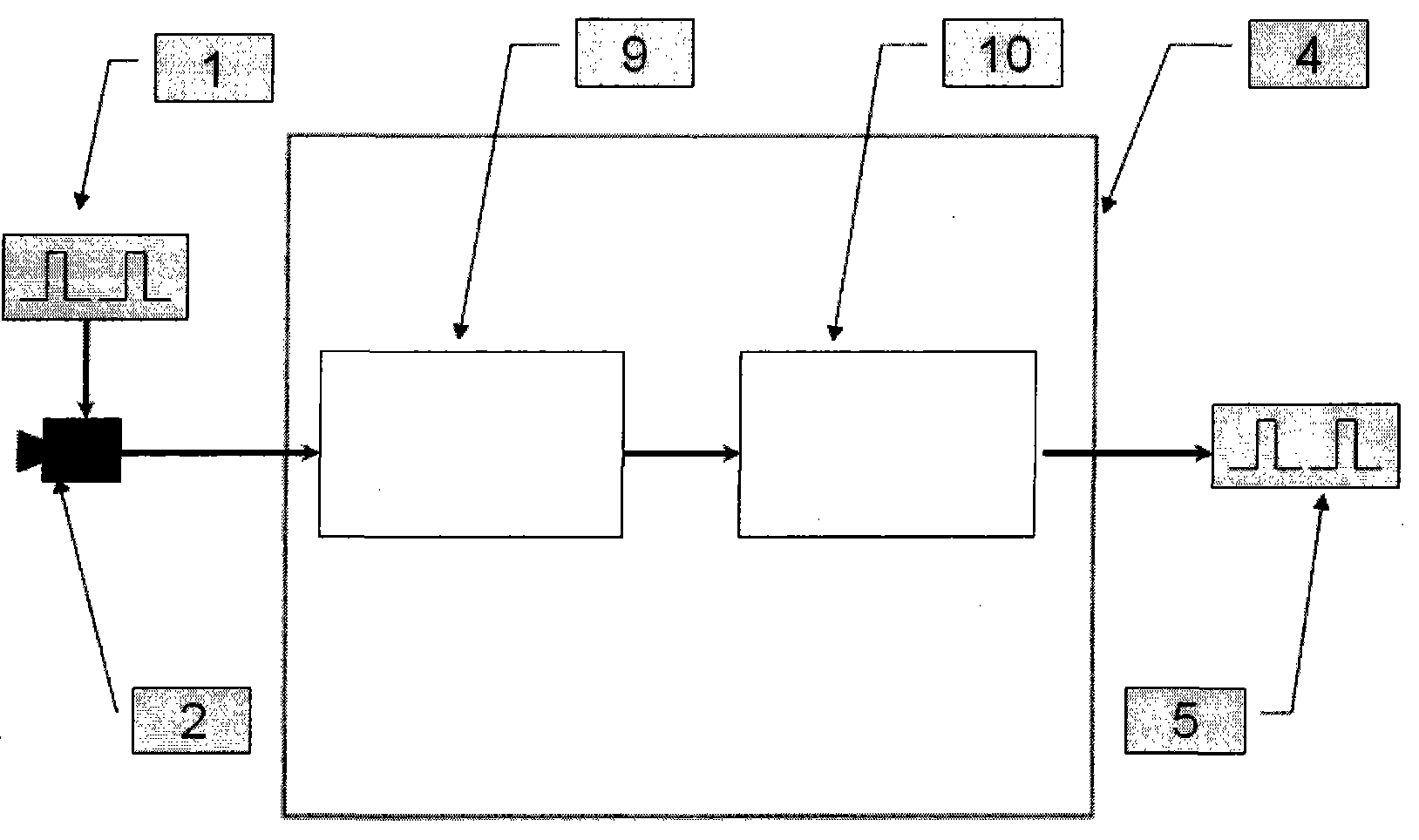

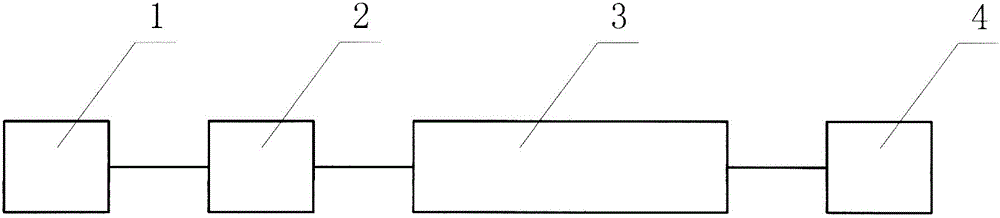

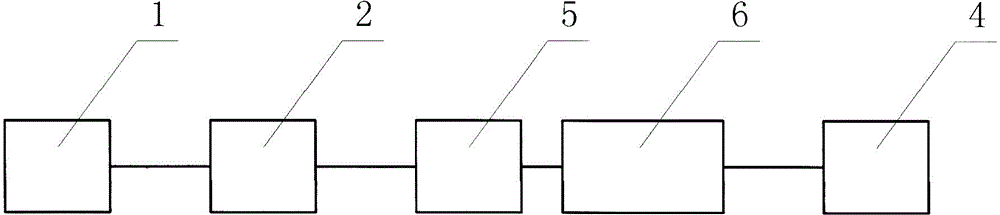

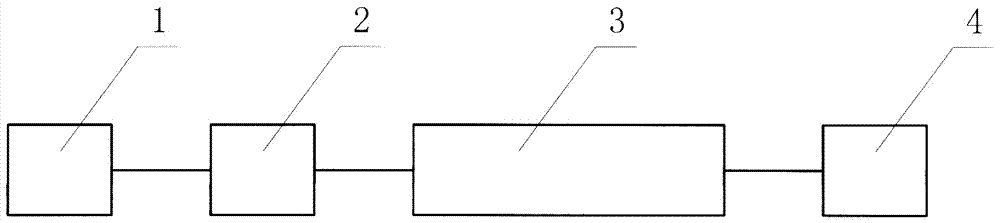

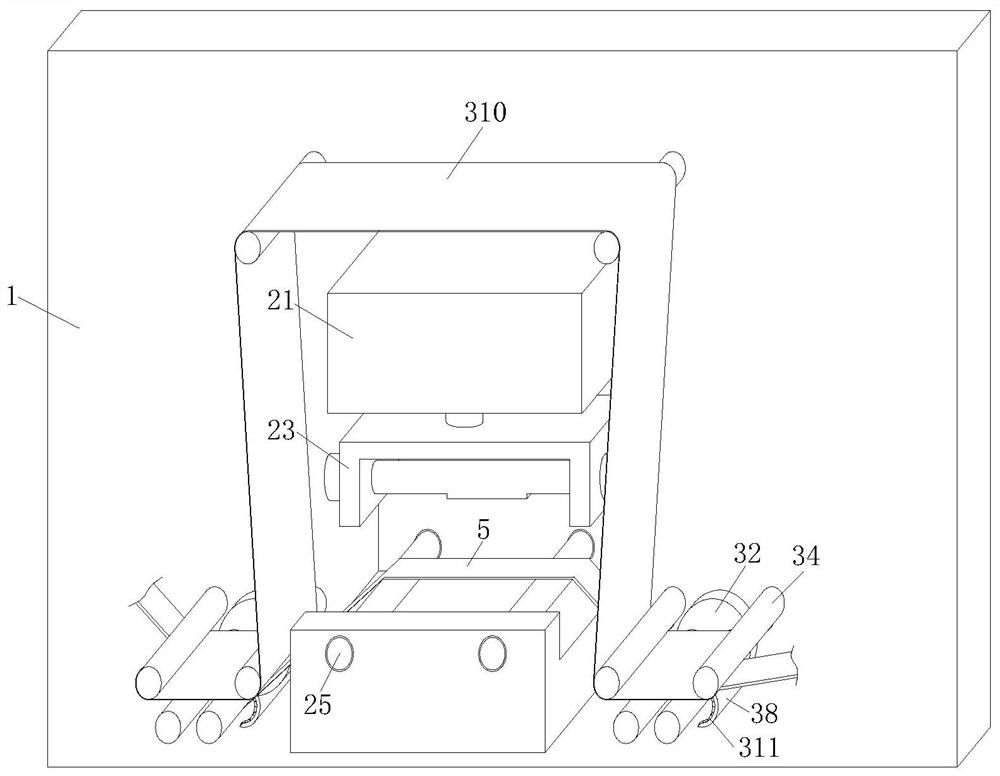

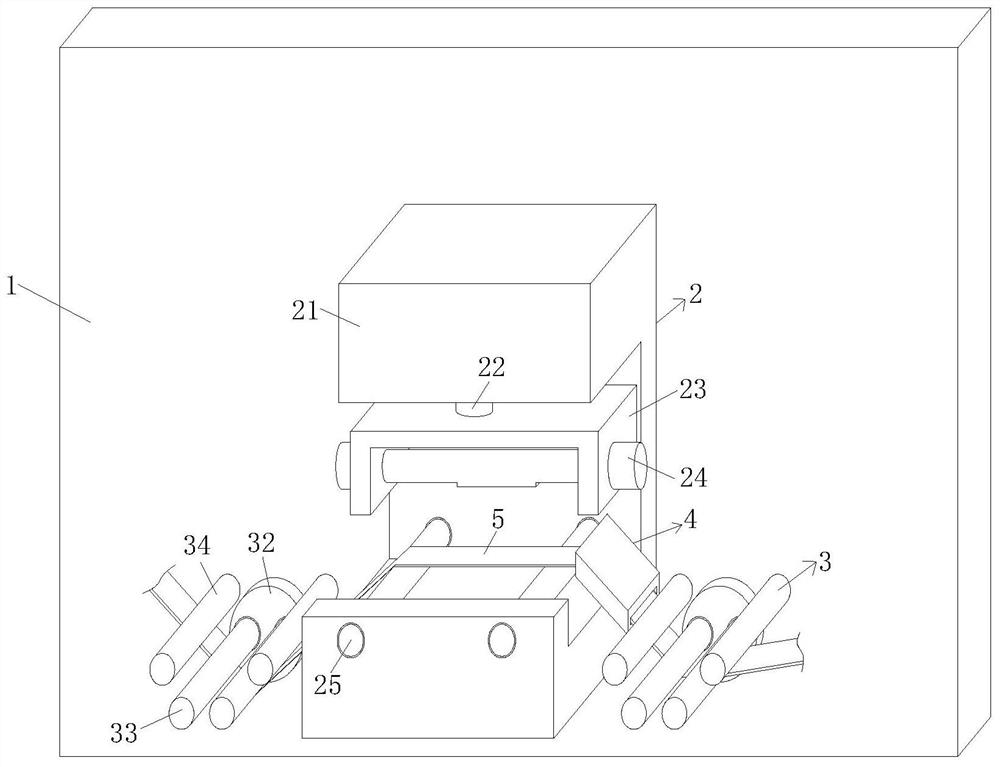

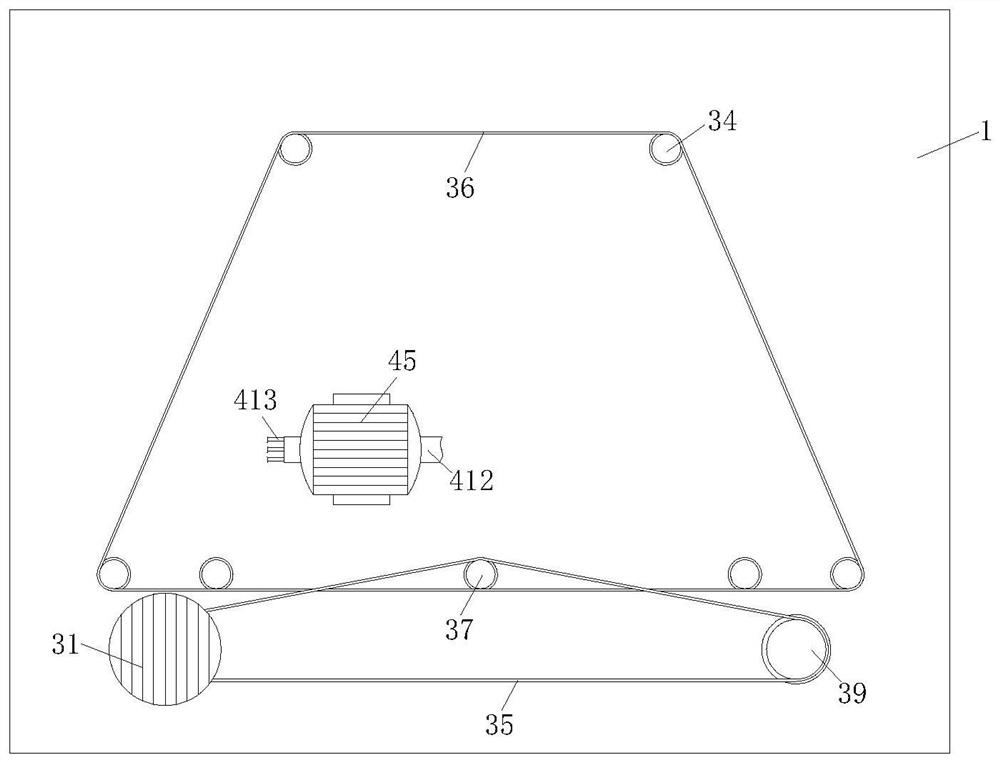

Medicine bottle label information online detection system in powder injection production based on mechanical vision

ActiveCN101566582BAvoid quality problemsQuality assuranceOptically investigating flaws/contaminationSortingMachine visionImaging processing

The invention provides a medicine bottle label online detection system in medical powder injection production based on mechanical vision, which comprises a photoelectric trigger device (1), an image sensing device (2), an LED rectangular light source device (3), an image processing and analyzing device (4) and an output control device (5). The system can effectively solve the quality problem in medicine bottle label during production, finds out unqualified medicine bottle labels in time, eliminates the unqualified medicine bottle labels, can carry out instant non-stop detection during high-speed production without affecting continuous production and favorably guarantees the quality of medicine. The invention has simple structure and is suitable for being applied to industrial production.

Owner:SHANGHAI NEW ASIA PHARMA

Automatic blister machine

ActiveCN110605846BEfficient removalReduce negative effects on physical healthGas treatmentDispersed particle separationActivated carbonExhaust fumes

The invention discloses an automatic plastic suction machine, which relates to the field of plastic suction equipment. The technical points are: an automatic plastic-absorbing machine, including a plastic-absorbing machine body, a suction hood is arranged on one side of the plastic-absorbing machine body, and a suction pipe is connected to the side of the suction hood far away from the plastic-absorbing machine body. The side of the exhaust gas treatment box away from the suction hood is provided with a waste gas treatment box, and the end of the waste gas treatment box away from the suction pipe is provided with a suction fan; the top and bottom of the waste gas treatment box are respectively equipped with a main winding roller and a secondary winding roller. Activated carbon cloth is wound around the winding roller, and the other end of the activated carbon cloth is fixedly connected with the auxiliary winding roller. One end of the rewinding roller and the secondary rewinding roller is respectively provided with a main driver and a secondary driver to drive them to rotate, and a protective cover is arranged around the main rewinding roller and the secondary rewinding roller. The invention has the advantages of removing organic waste gas and reducing pollution.

Owner:苏州耀鑫新型包装材料有限公司

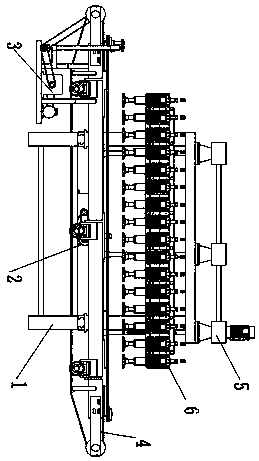

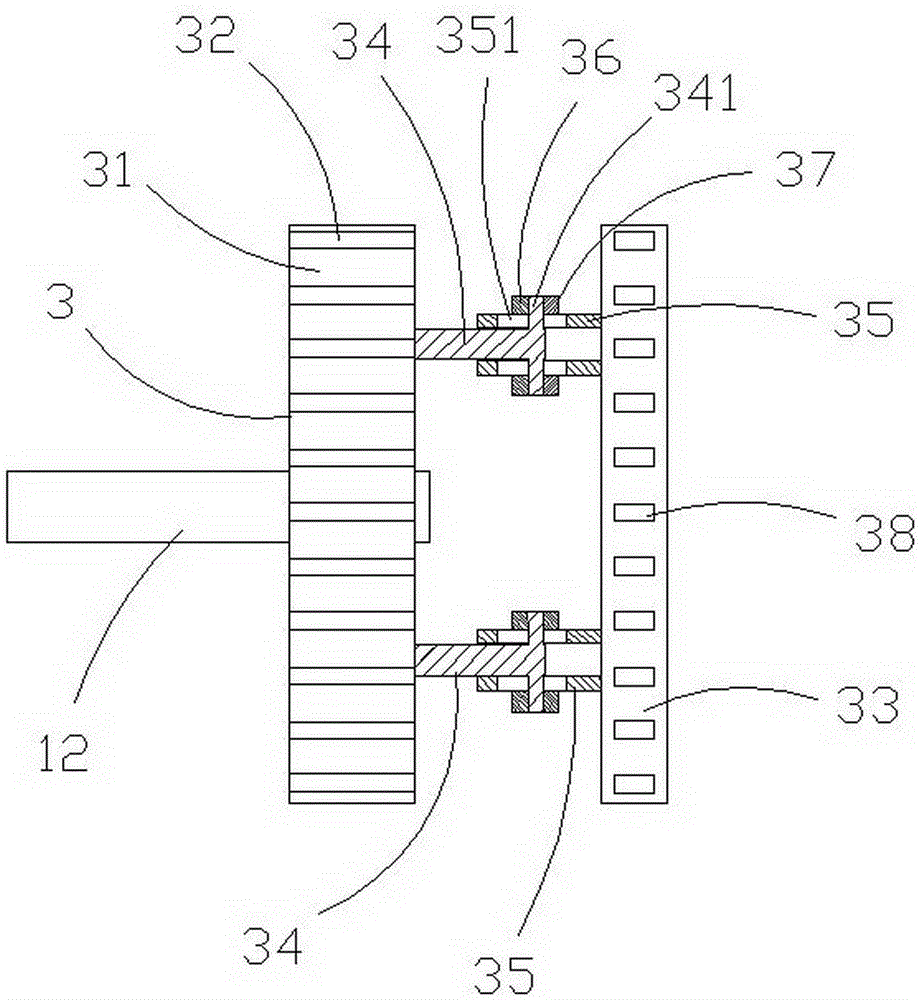

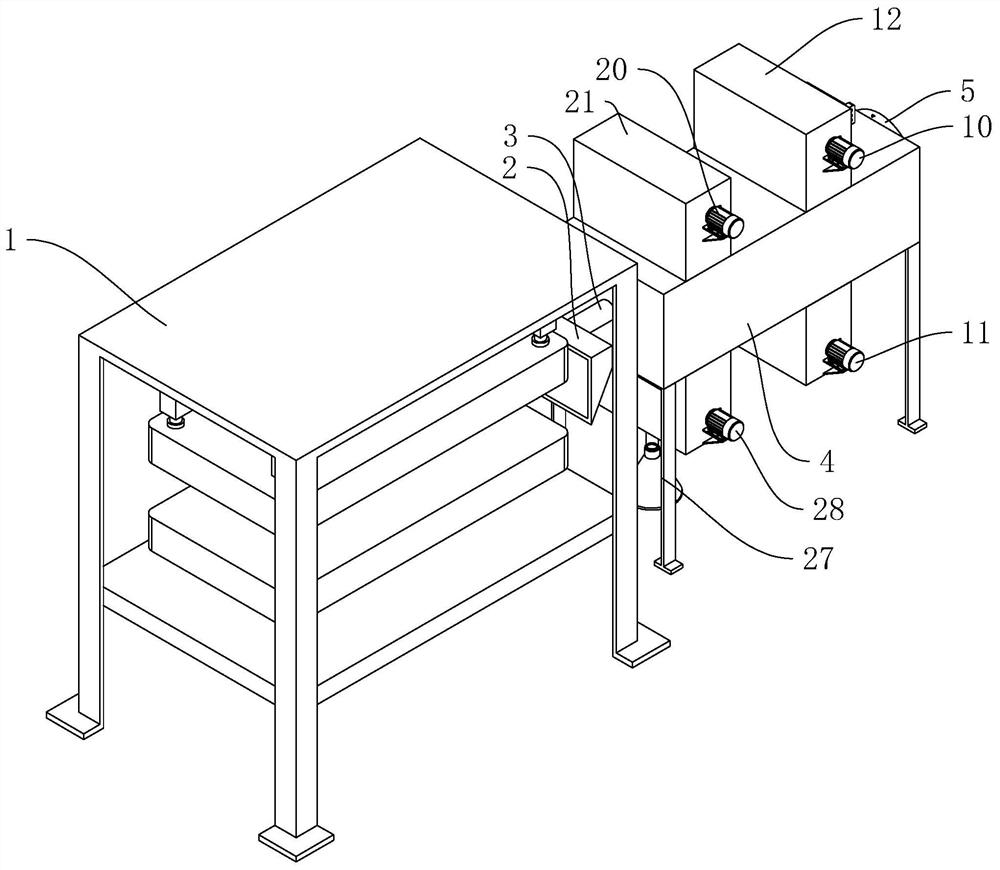

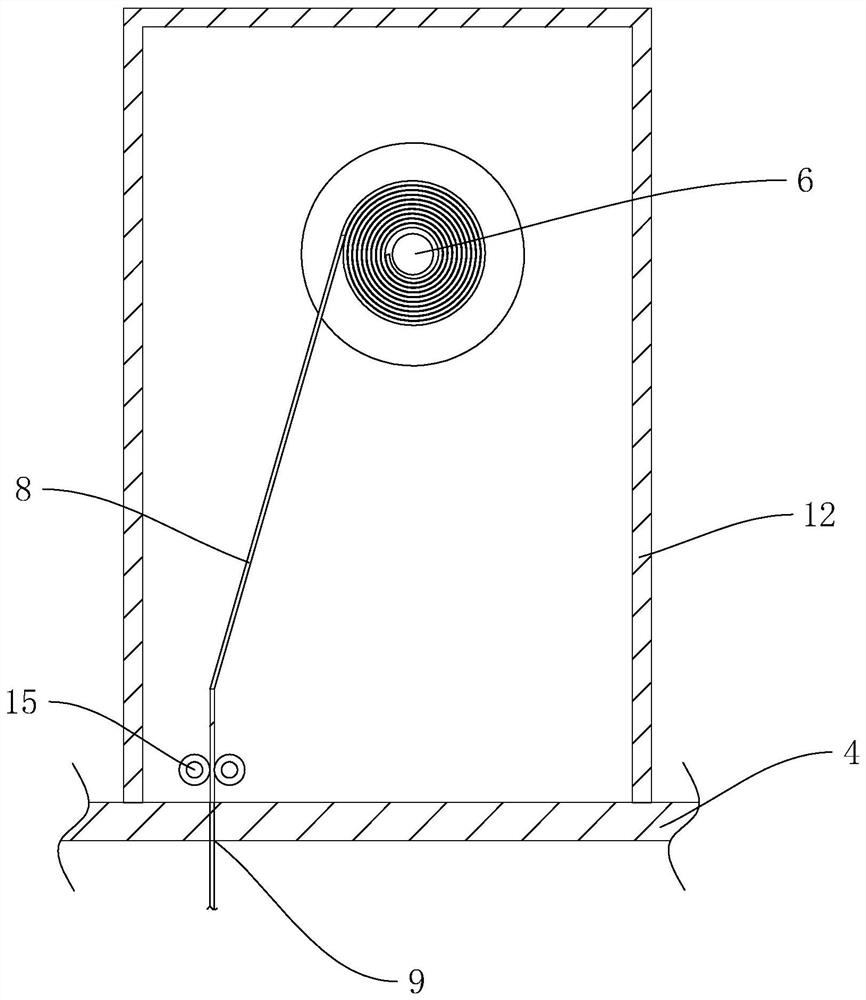

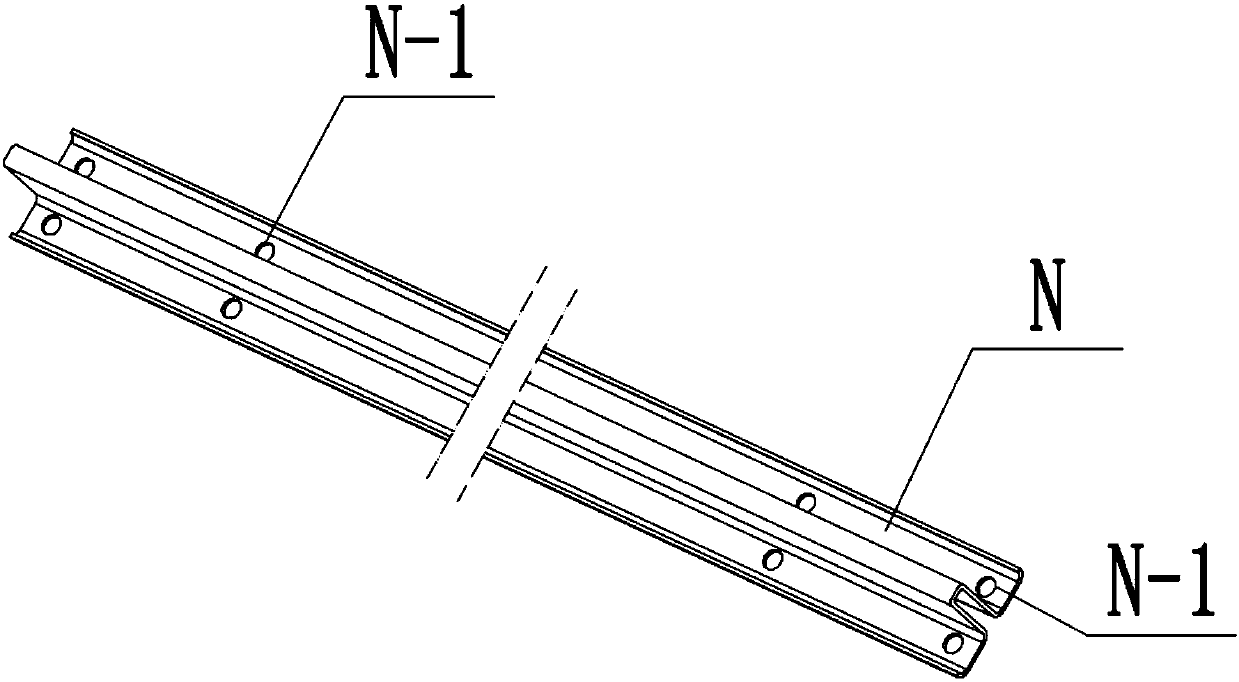

Sizing machine pasting table modular structure

InactiveCN103316808BDoes not affect continuous productionRealize offline roll changeLiquid surface applicatorsCoatingsPulp and paper industryModular structure

The invention relates to a pulp sizing machine paste table modular structure comprising a paste table side wall (3), wherein the paste table side wall (3) has a Haff-type structure; a pulp controlling roller (1) and a pulp sizing roller (2) are installed on the paste table side wall (3) by virtue of bearings and expansion sleeves; a sliding block (4) is fixedly installed at the lower end face of the paste table side wall (3); a fixed slideway seat (5) is installed on the inner side of a fixed wall 6; the paste table side wall (3) as well as the pulp controlling roller (1) and the pulp sizing roller (2) installed on the paste table side wall (3) form an integral type paste table module; the paste table module is in sliding fit with a guide rail of the fixed slideway seat (5) by virtue of the sliding block (4). Maintenance, assembly and washing are convenient and efficient.

Owner:湖南益晟机械科技有限公司

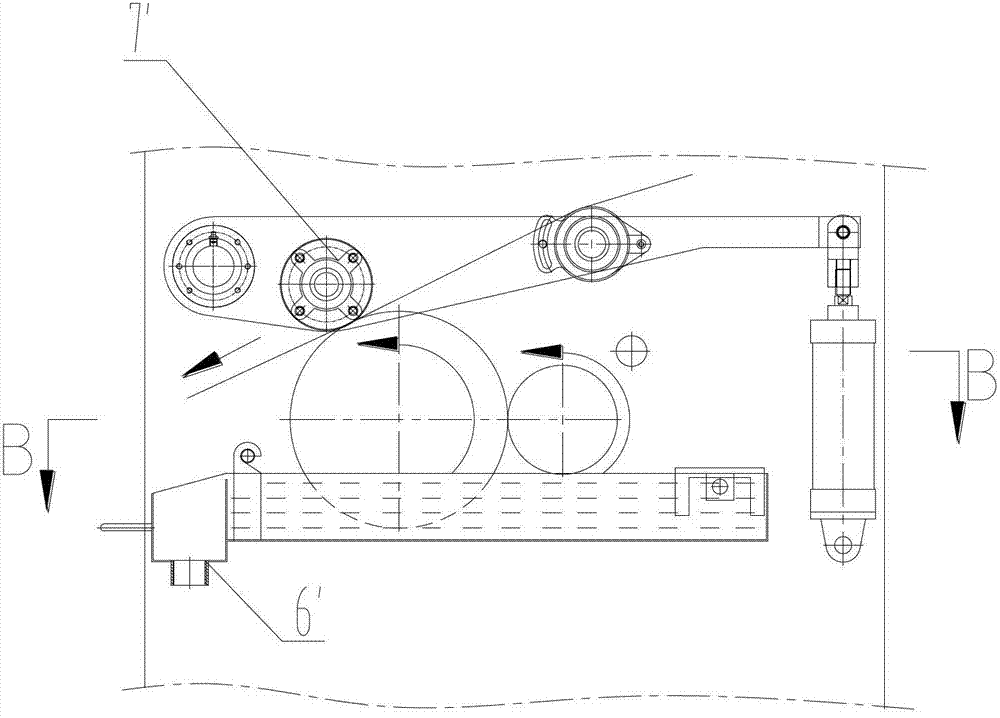

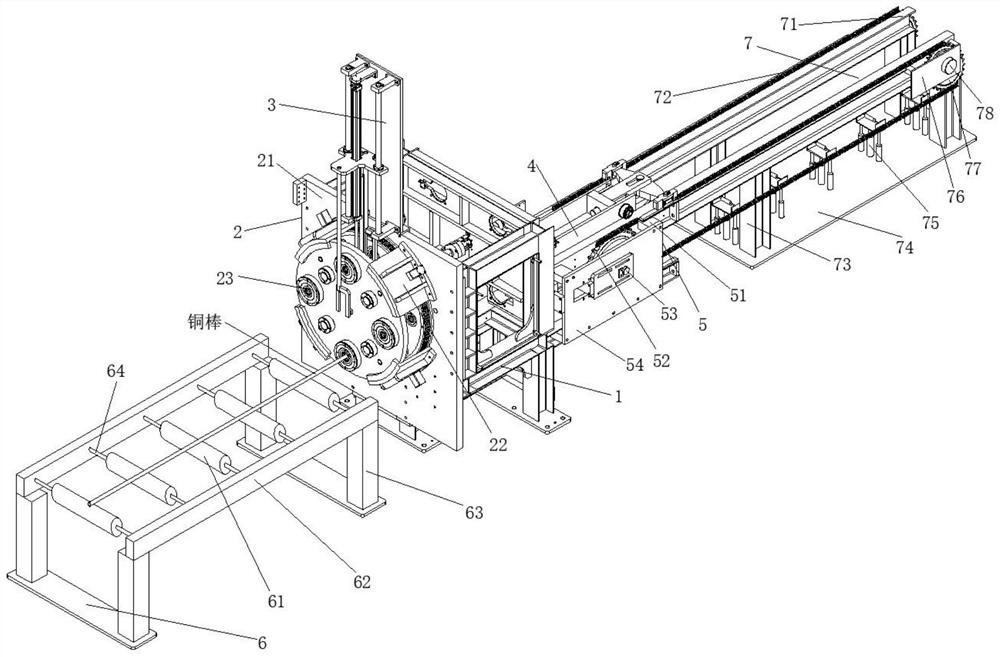

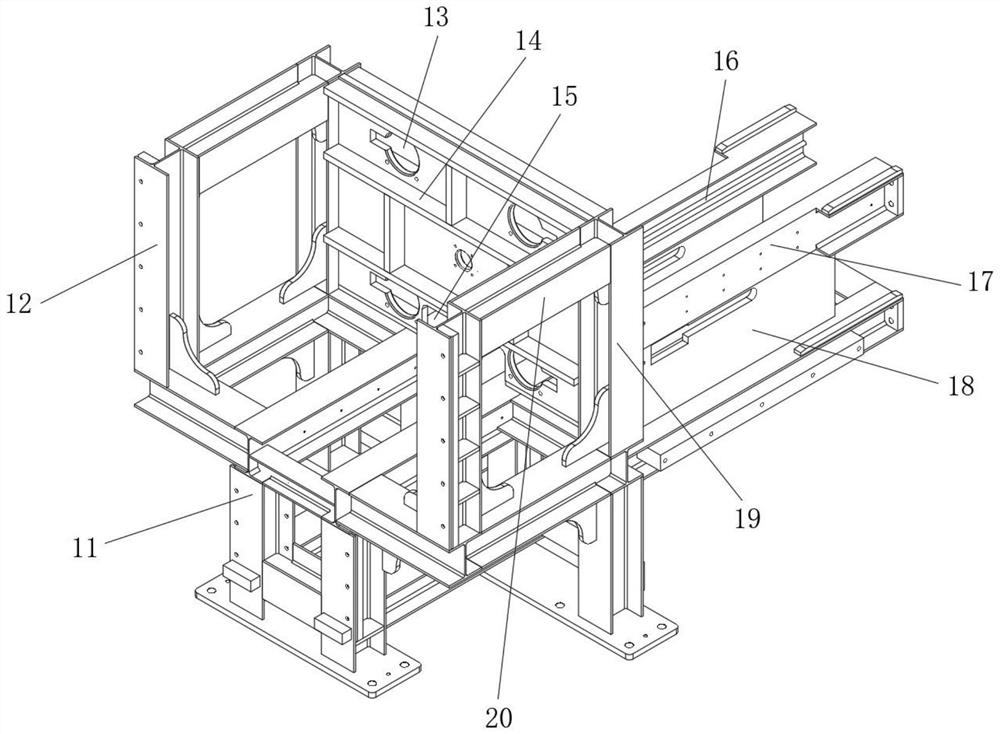

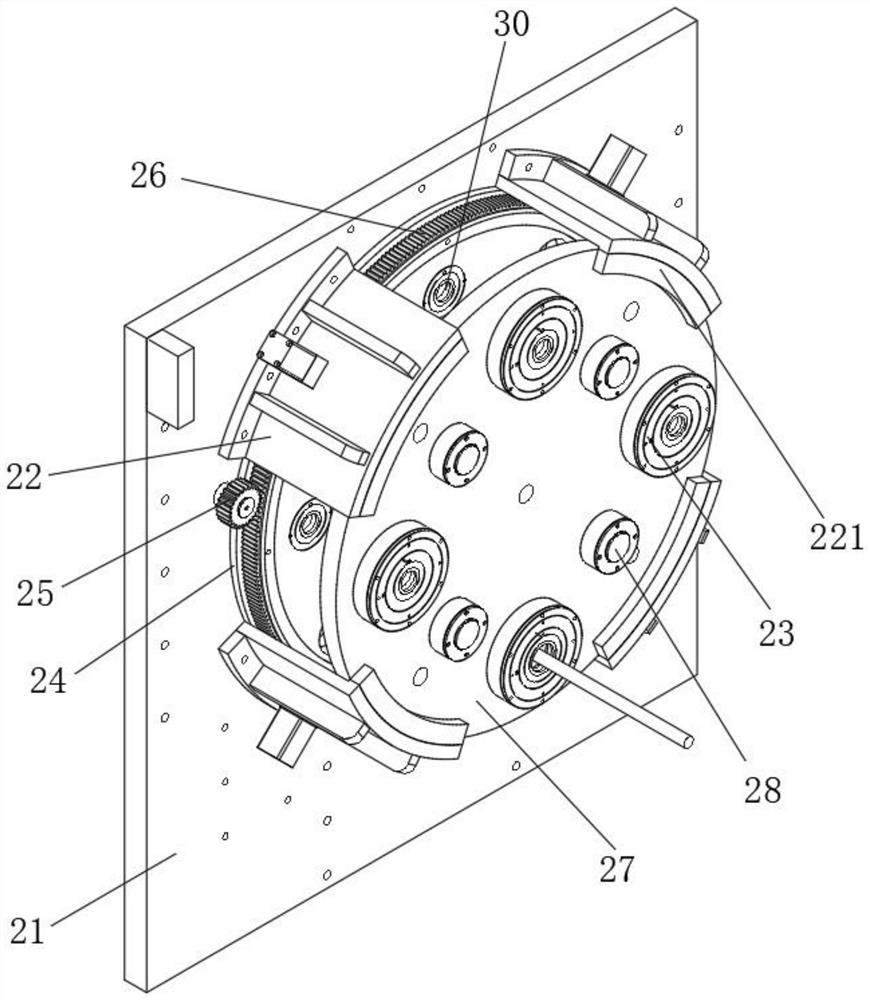

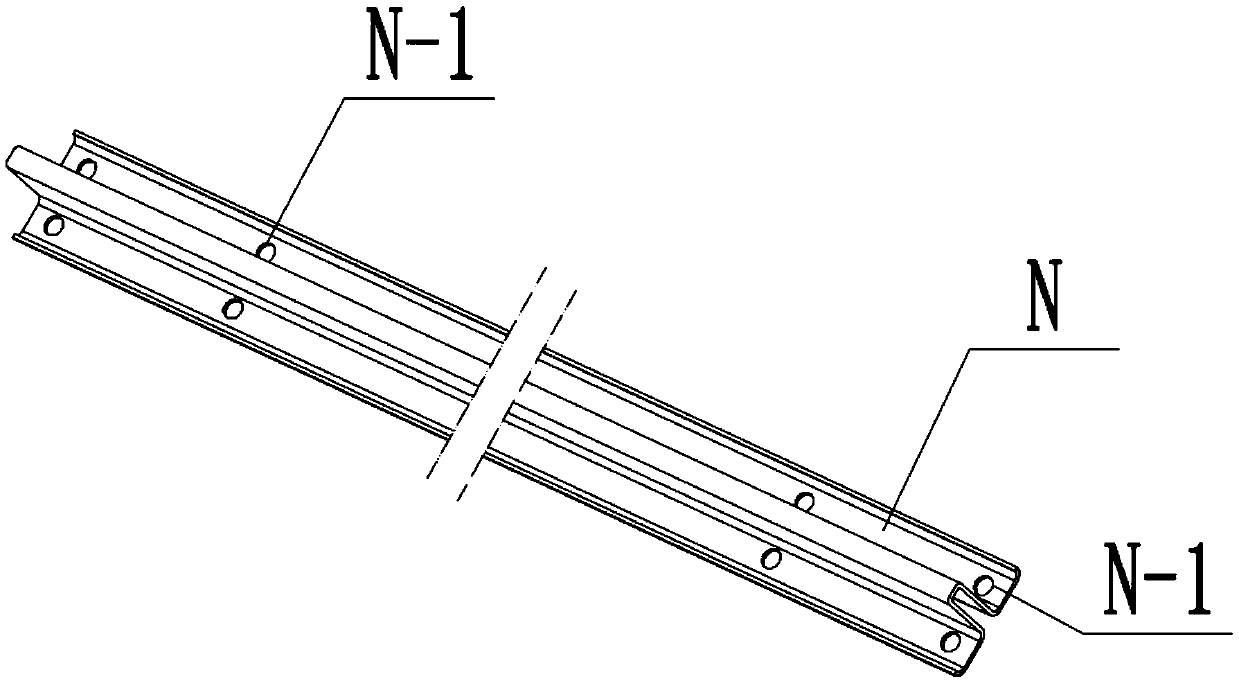

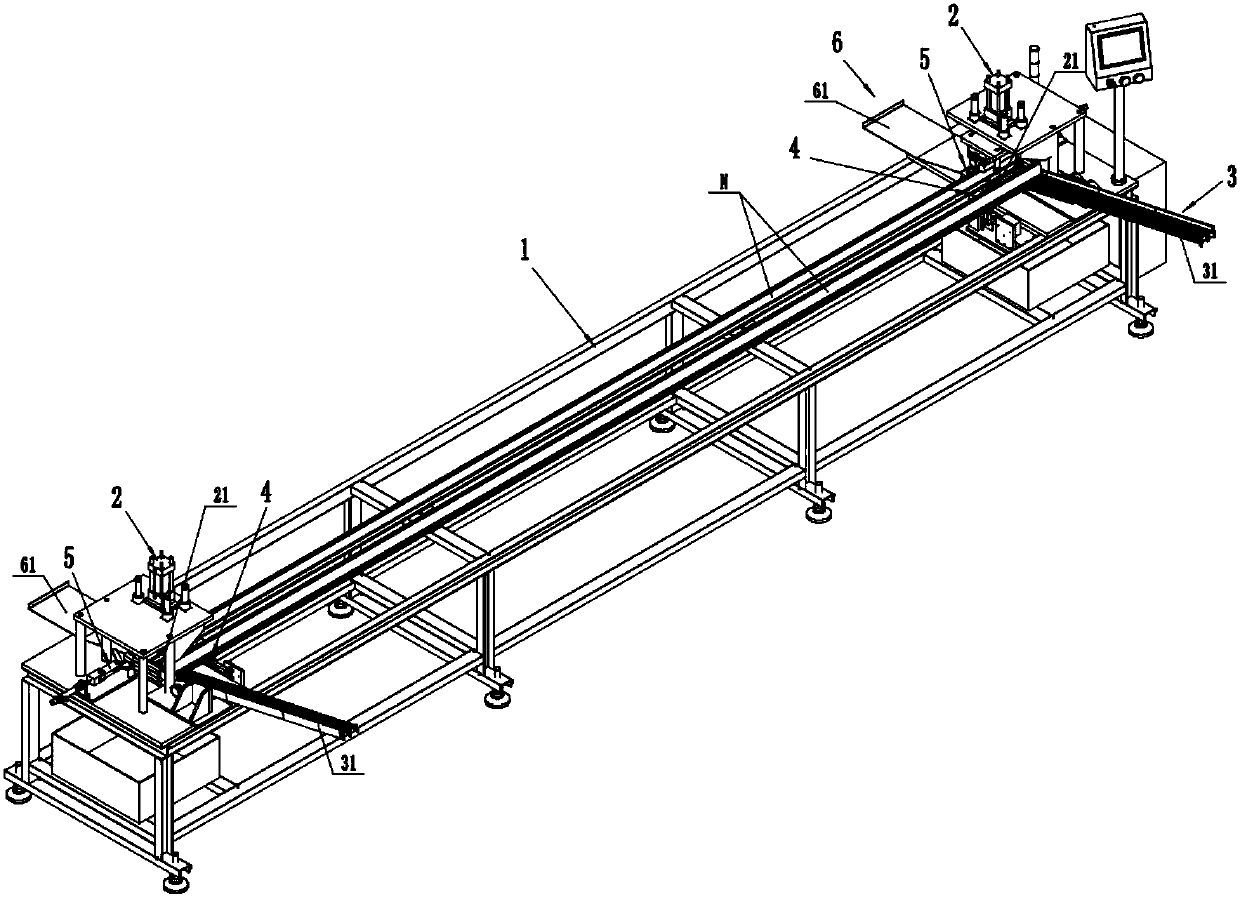

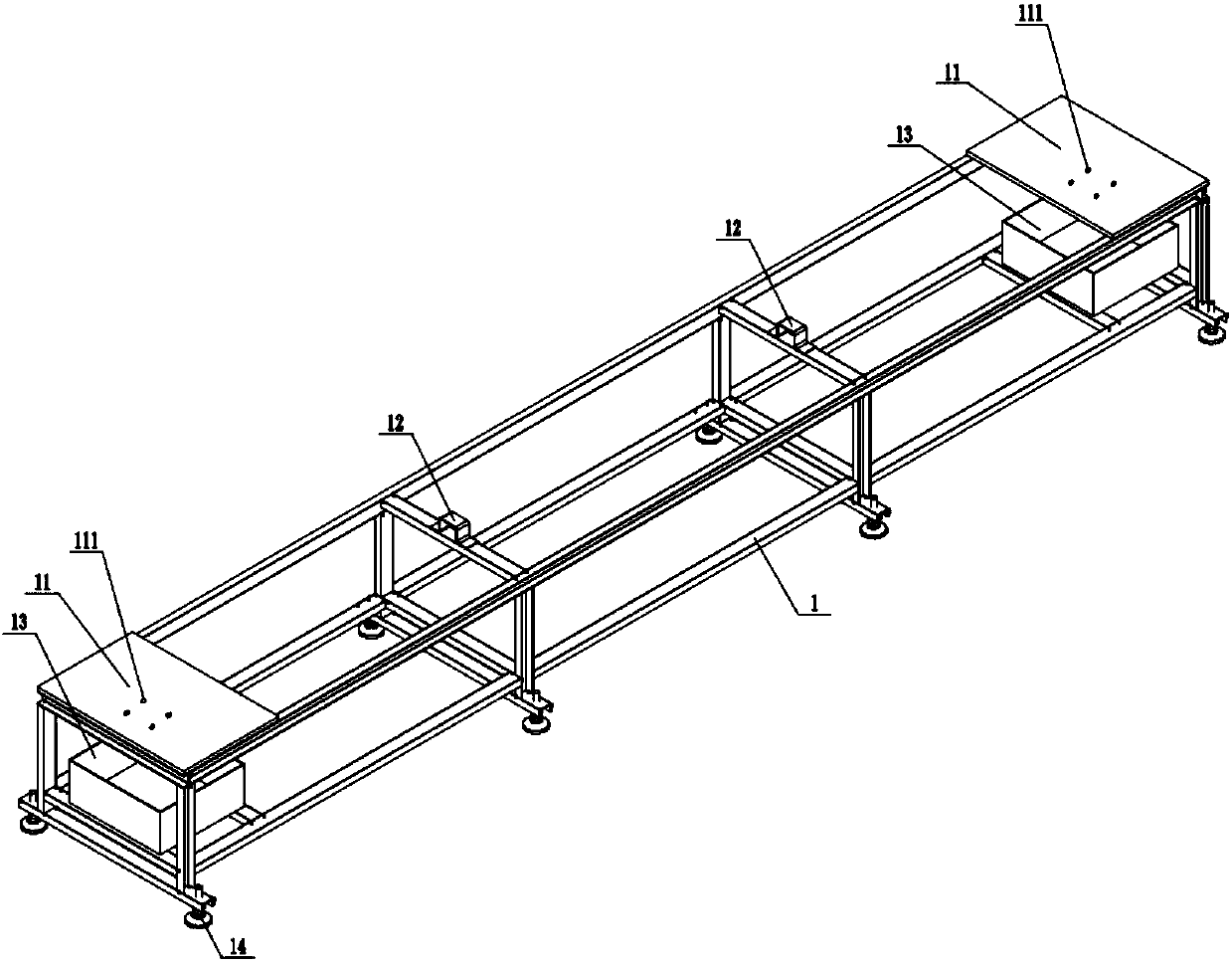

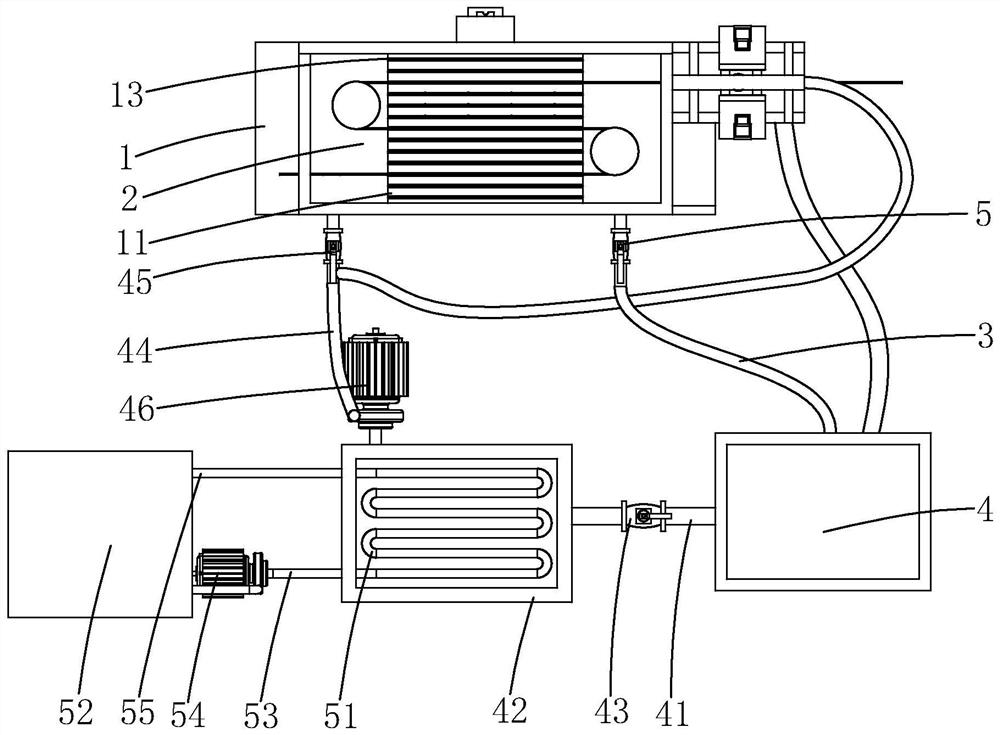

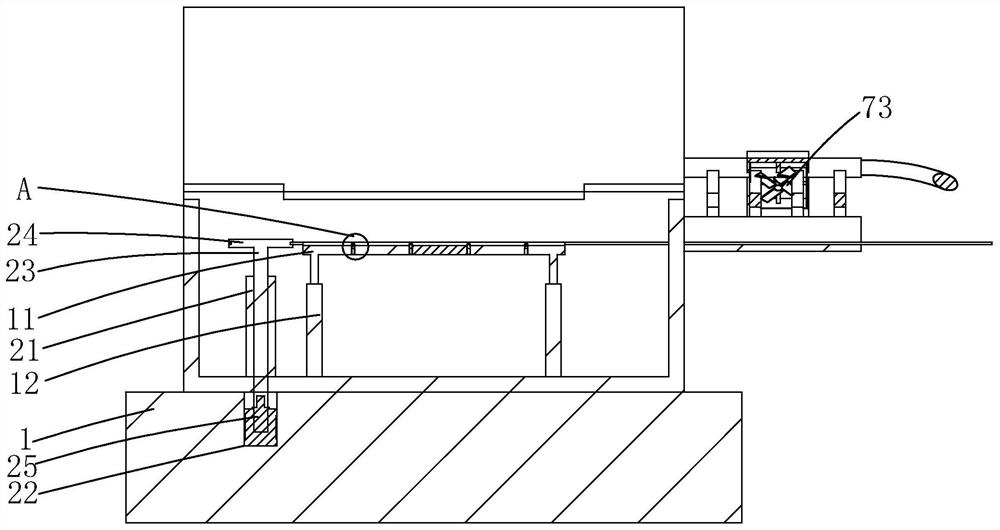

A double-chain multi-mode peeling device for copper rods

ActiveCN113523442BEasy to operateDoes not affect continuous productionMetal working apparatusChain linkDouble chain

The patent of the present invention discloses a double-chain multi-mode peeling device for copper rods, which includes a bracket on which a peeling mechanism and a pulling rod trolley are arranged in sequence. For the rod clamping mechanism, a transmission mechanism is symmetrically arranged on the front and rear sides of the bracket located on both sides of the pulling rod trolley. A conveying mechanism is placed next to one side of the bracket of the trolley, and the conveying mechanism is connected with the transmission mechanism through a chain drive. The patent of the invention can continuously produce and save raw materials, and at the same time, the peeling mold can be replaced at any time according to the needs, so that the productivity is improved, and the adaptability is stronger.

Owner:浙江硕实机械有限公司

A kind of potassium nitrate anti-caking agent and its preparation and use method

ActiveCN106116806BGood anti-caking performanceNo clumpingNitrate fertilisersFertilizer mixturesPotassium nitrateFoaming agent

The invention relates to a potassium nitrate anti-blocking agent and preparation and application methods thereof. The anti-blocking agent is prepared from, by mass, 25%-55% of water, 15%-25% of crystal control agent, 15%-30% of dispersing agent, 0.5%-15% of wrapping agent, 0.5%-10% of emulgator and 2%-15% of diluents. The invention relates to the preparation method of the anti-blocking agent. The preparation method comprises the steps that sequential blending is carried out; stirring is carried out till even dispersing is achieved. During use, the anti-blocking agent is evenly smeared to the surfaces of potassium nitrate crystals after being atomized, and finally the anti-blocking agent and the potassium nitrate crystals are dried together. The anti-blocking agent and the preparation and application methods thereof have the advantages that anti-blocking performance is good, cost is low, the preparation method is simple, use is convenient, and normal production of potassium nitrate is not influenced, and good application prospects are achieved.

Owner:KINGENTA ECOLOGICAL ENG GRP

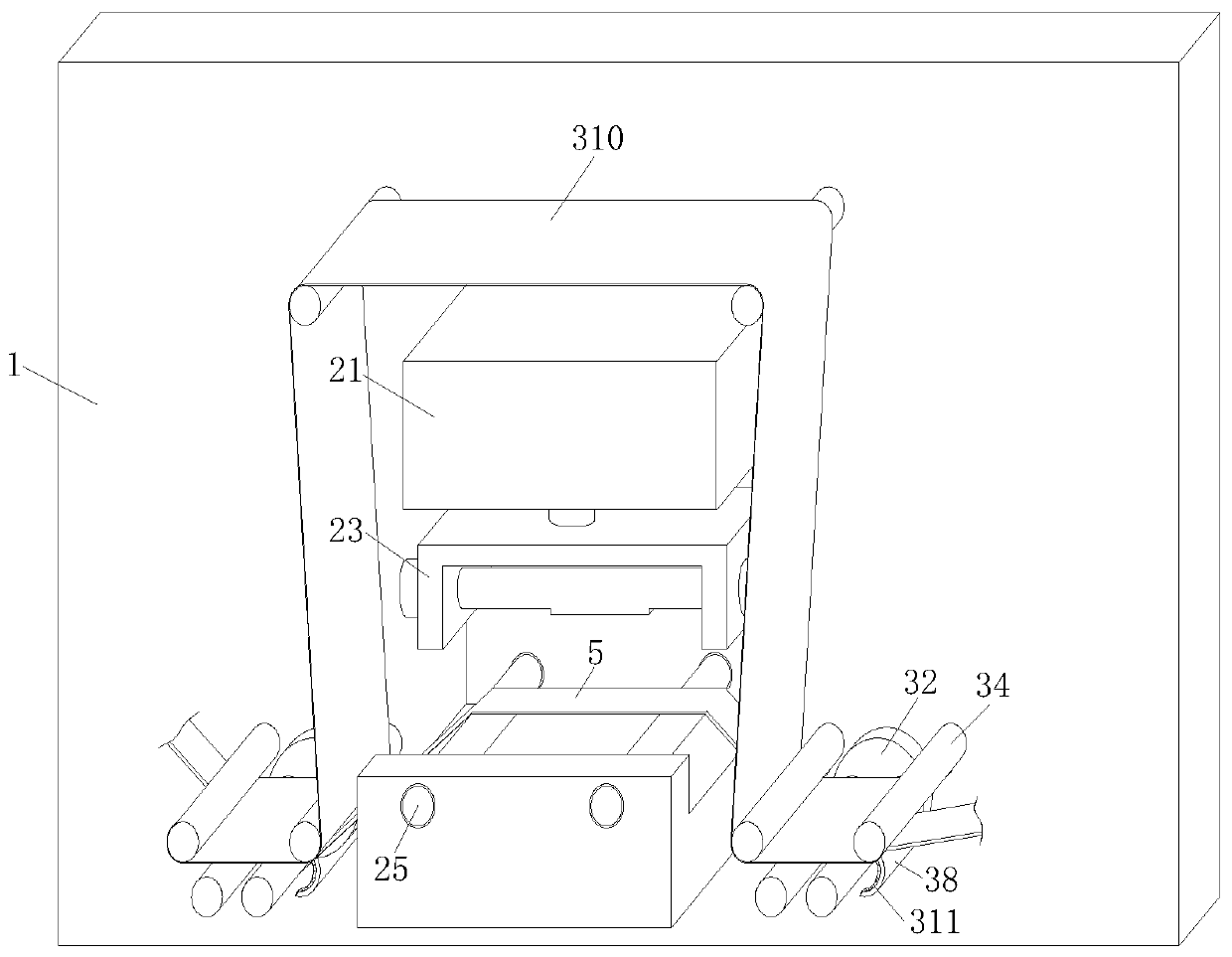

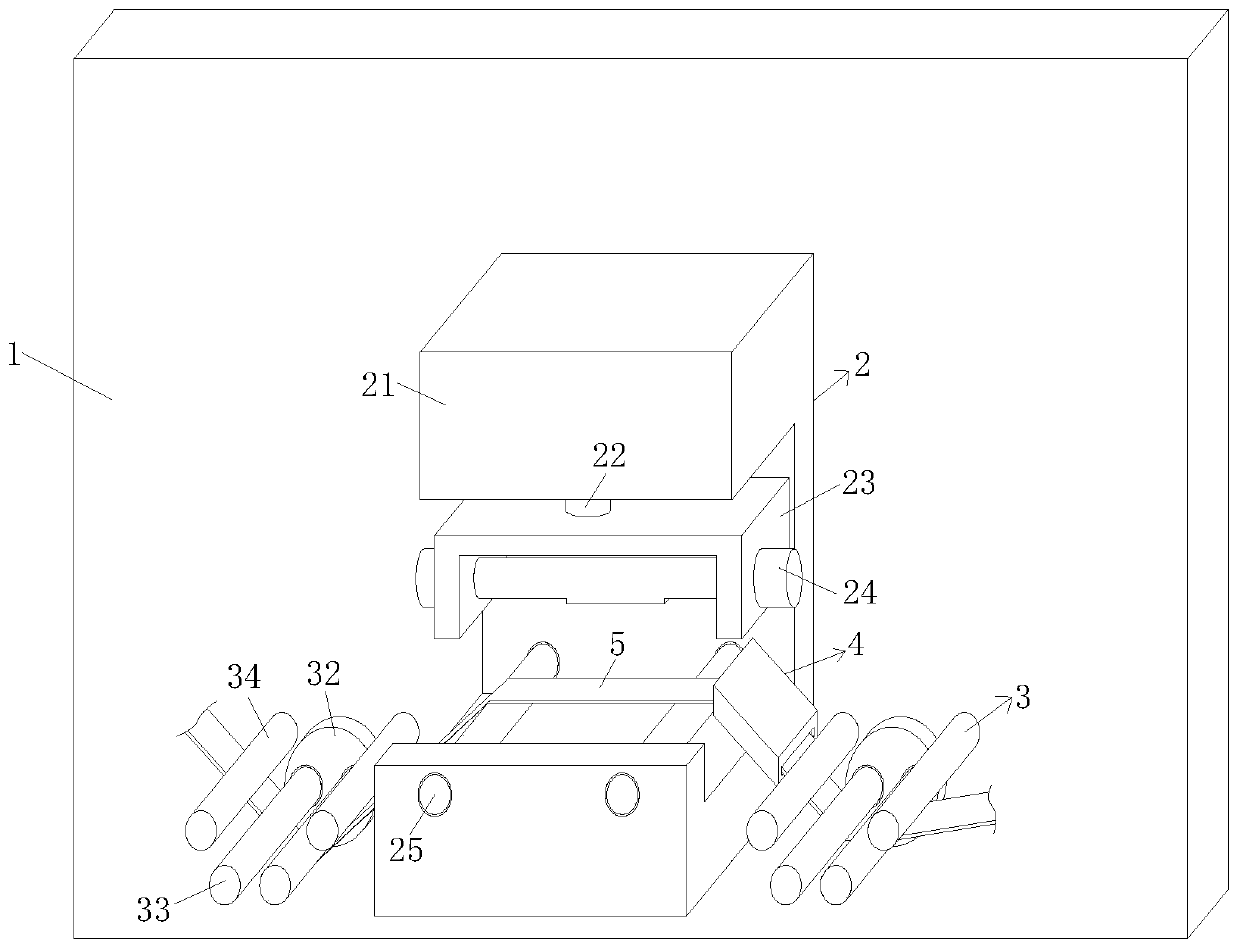

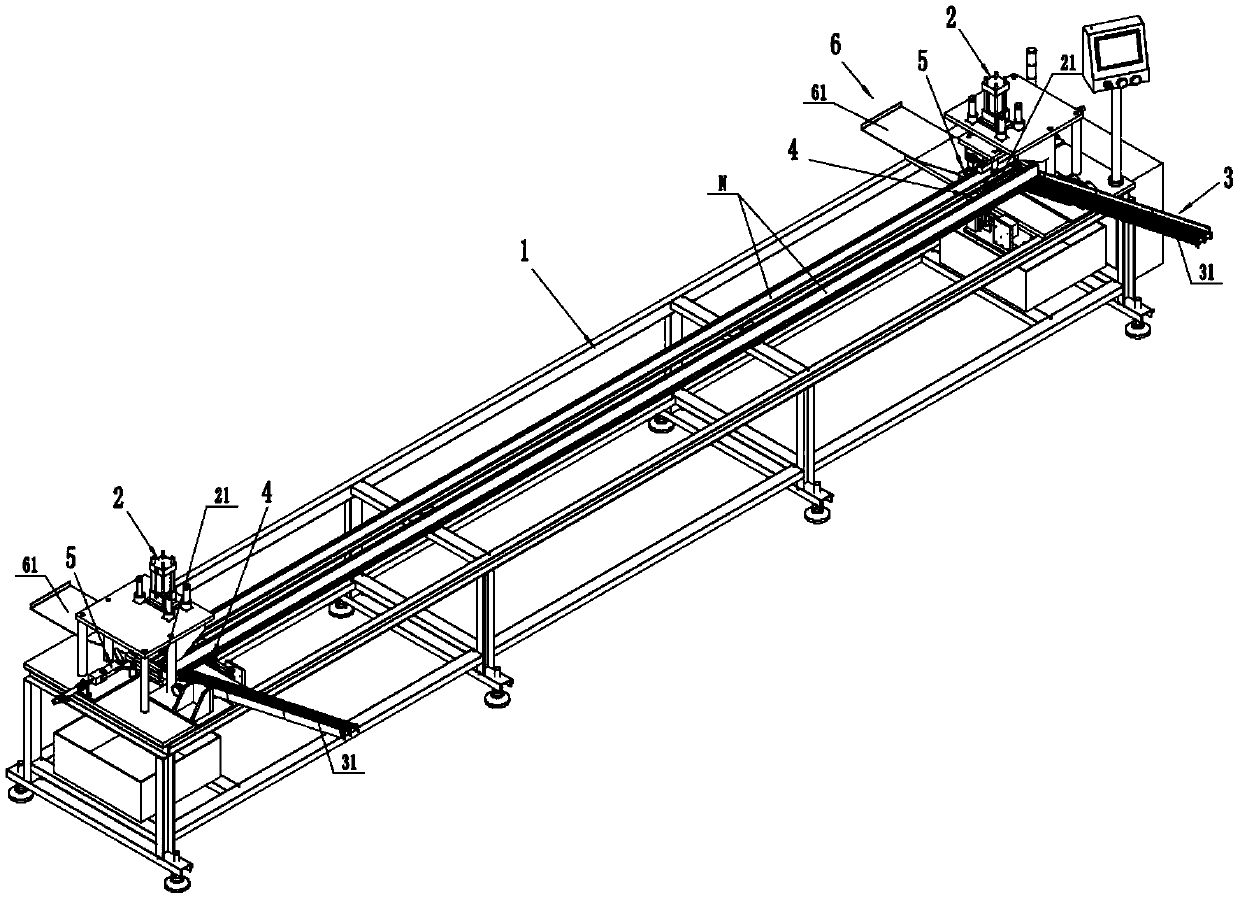

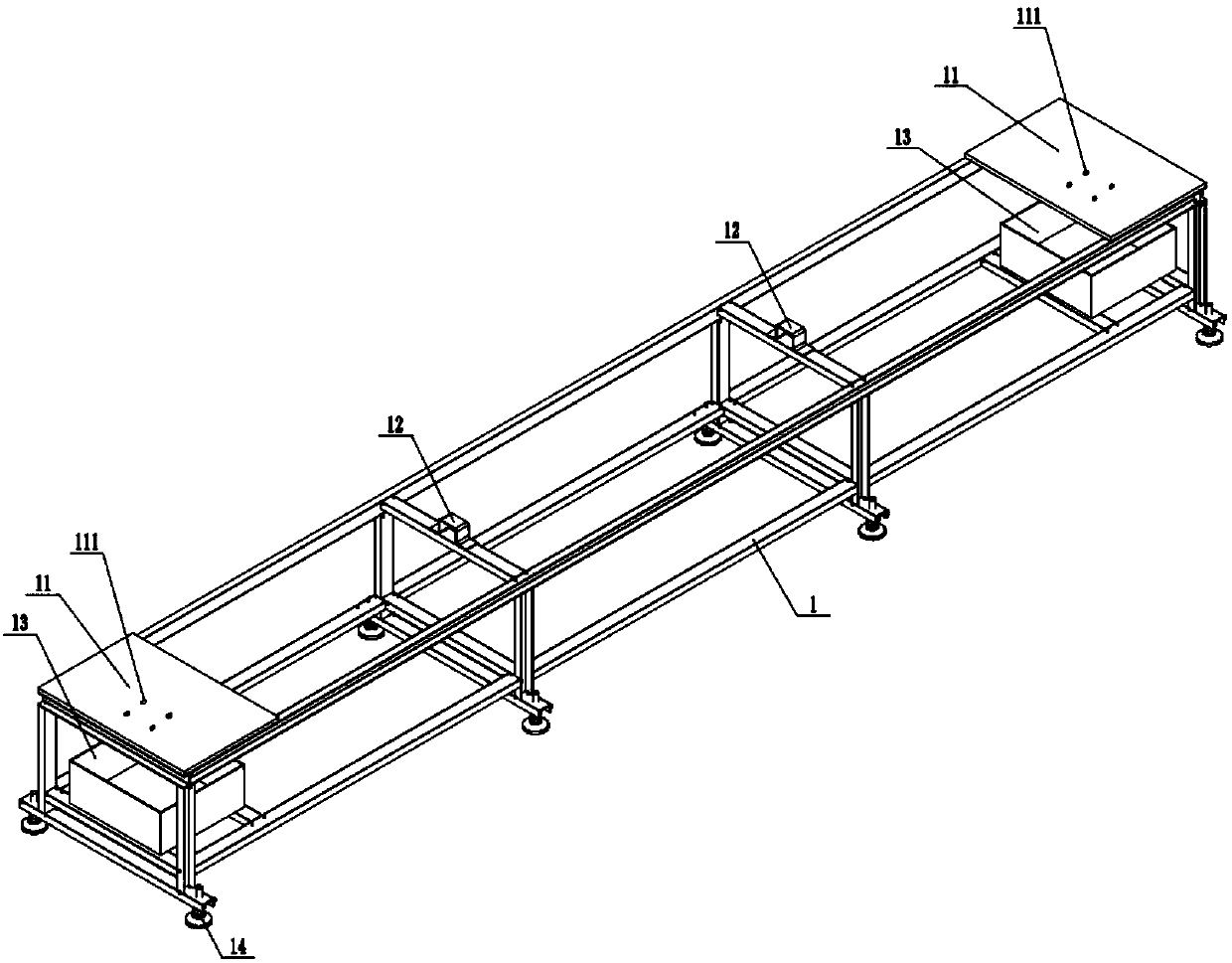

Synchronous punching equipment at both ends of a few-shaped steel beam

ActiveCN107737834BEasy to produceReduce labor intensityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses n-shaped steel beam two-end synchronous punching equipment. The n-shaped steel beam two-end synchronous punching equipment comprises a machine frame, two punching mechanisms, amaterial placing frame, a material passing control mechanism, a material blocking control mechanism and a material receiving frame; the two punching mechanisms are arranged on the two sides of the machine frame in the length direction correspondingly; the material placing frame and the material receiving frame are positioned on the two sides of the machine frame in the width direction correspondingly; the material placing frame is provided with an inclined discharging support; the material passing control mechanism is used for performing blocking and passing control on an n-shaped steel beamat the lowest position of the inclined discharging support; the two ends of the n-shaped steel beam slide on the workbenches of the two punching mechanism correspondingly after the material passing control mechanism allows to pass; the material blocking control mechanism is used for performing positioning blocking during processing of the n-shaped steel beam on the machine frame and performing passing control after processing; and the material receiving frame is provided with a material receiving support. The n-shaped steel beam two-end synchronous punching equipment can perform punching processing on the two ends of the n-shaped steel beam simultaneously, can perform secondary positioning processing without turning 180 degrees and can realize automatic continuous production.

Owner:芜湖恒驰钢构有限公司

Waste rock discharging and sorting comprehensive treatment method for underground lump coal

Owner:SHENYANG TIAN AN TECH CO LTD

Inoculation, nursing and primordium inducing factory system of Pleurotus eryngii

ActiveCN104303844AInfrequent accessFast growthCultivating equipmentsMushroom cultivationDiseaseZoology

An inoculation, nursing and primordium inducing factory system of Pleurotus eryngii employs phases of distributing, bagging, sterilizing, cooling, inoculating, mycelium culturing, primordium generating (primordium inducing) and mushroom raising. The system is characterized in that the mycelium culturing phase includes primary mycelium culturing and secondary mycelium culturing, the inoculating phase and the primary mycelium culturing are performed in a primary culturing shop, the secondary mycelium culturing and the primordium generating (primordium inducing) are performed in a secondary culturing shop, and after primordium generating, transit to a fruiting shop is performed for mushroom raising. The system has the advantages that inoculating success rate is high, mushroom dead and rot caused by mushroom distortion and diseases occurring due to a large temperature difference can be avoided, growth speed of Pleurotus eryngii is increased, whole-course continuous factory production is achieved, yield is increased, product quality is improved, raising time is shortened, sterilizing time is shortened, and operating cost is lowered.

Owner:SHANXI KINGSHINE FERTILIZER

Secondary air nozzle of rotary kiln

ActiveCN101368737BEasy to installAvoid damageRotary drum furnacesMaintainance of heating chambersCombustionThermal insulation

The invention discloses a rotary kiln secondary air nozzle which comprises a nozzle air channel fixed on the kiln crust of the rotary kiln and communicated with the external air channel of the rotary kiln; a heat insulation retaining component is arranged in the nozzle air channel; the heat insulation retaining component is positioned on one end of the nozzle air channel, which is connected with the external air channel of the rotary kiln. The rotary kiln secondary air nozzle has the advantages of insulating part of the irradiation heat inside the rotary kiln and preventing the fuel in the high temperature combustion state from flowing into the external air channel of the rotary kiln.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A kind of method for inoculating Pleurotus eryngii to inoculate, cultivate and promote buds

An inoculation, nursing and primordium inducing factory system of Pleurotus eryngii employs phases of distributing, bagging, sterilizing, cooling, inoculating, mycelium culturing, primordium generating (primordium inducing) and mushroom raising. The system is characterized in that the mycelium culturing phase includes primary mycelium culturing and secondary mycelium culturing, the inoculating phase and the primary mycelium culturing are performed in a primary culturing shop, the secondary mycelium culturing and the primordium generating (primordium inducing) are performed in a secondary culturing shop, and after primordium generating, transit to a fruiting shop is performed for mushroom raising. The system has the advantages that inoculating success rate is high, mushroom dead and rot caused by mushroom distortion and diseases occurring due to a large temperature difference can be avoided, growth speed of Pleurotus eryngii is increased, whole-course continuous factory production is achieved, yield is increased, product quality is improved, raising time is shortened, sterilizing time is shortened, and operating cost is lowered.

Owner:SHANXI KINGSHINE FERTILIZER

N-shaped steel beam two-end synchronous punching equipment

ActiveCN107737834AEasy to produceReduce labor intensityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses n-shaped steel beam two-end synchronous punching equipment. The n-shaped steel beam two-end synchronous punching equipment comprises a machine frame, two punching mechanisms, amaterial placing frame, a material passing control mechanism, a material blocking control mechanism and a material receiving frame; the two punching mechanisms are arranged on the two sides of the machine frame in the length direction correspondingly; the material placing frame and the material receiving frame are positioned on the two sides of the machine frame in the width direction correspondingly; the material placing frame is provided with an inclined discharging support; the material passing control mechanism is used for performing blocking and passing control on an n-shaped steel beamat the lowest position of the inclined discharging support; the two ends of the n-shaped steel beam slide on the workbenches of the two punching mechanism correspondingly after the material passing control mechanism allows to pass; the material blocking control mechanism is used for performing positioning blocking during processing of the n-shaped steel beam on the machine frame and performing passing control after processing; and the material receiving frame is provided with a material receiving support. The n-shaped steel beam two-end synchronous punching equipment can perform punching processing on the two ends of the n-shaped steel beam simultaneously, can perform secondary positioning processing without turning 180 degrees and can realize automatic continuous production.

Owner:芜湖恒驰钢构有限公司

A kind of production equipment and process of fire-resistant power cord

ActiveCN111516242BEasy dischargeImprove efficiencyDomestic articlesCoatingsWater storageThermodynamics

The invention relates to the technical field of production of fire-resistant power cord equipment, in particular to a fire-resistant power cord production equipment. It includes: an inlet, a forming section, an extruding section, an outlet and a stretching device. A cooling pool containing water is hinged on the bearing surface of the support table, one of the opposite sides of the cooling pool is provided with a water outlet hose, and one side of the support table is provided with a water storage hose connected with the water outlet hose The circumference of the water outlet hose is provided with an electric switch valve. When the water in the water tank needs to be replaced, the invention can facilitate the water to be discharged from the water tank, and it is not necessary for staff to take water manually, which improves the efficiency and saves manpower and material resources.

Owner:深圳市奋进达通讯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com