Multi-head character die

A font and multi-head technology, applied in the field of printing equipment on the surface of circular workpieces, can solve problems such as troubles and affecting production efficiency, and achieve the effect of improving production efficiency and fast conversion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

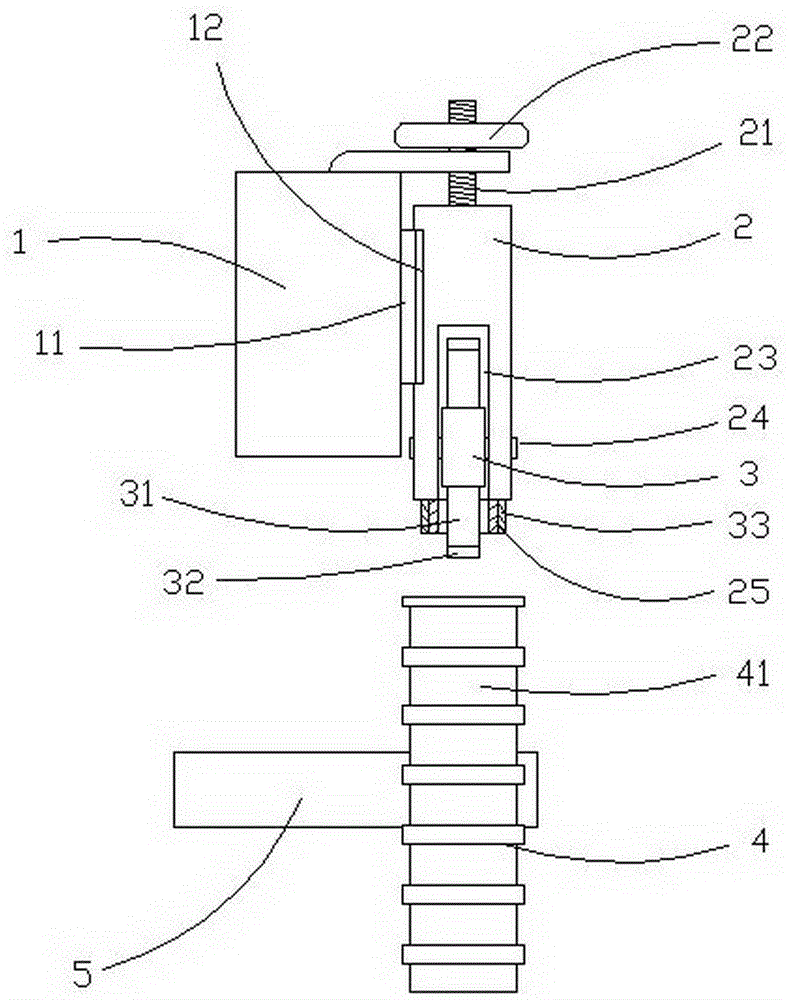

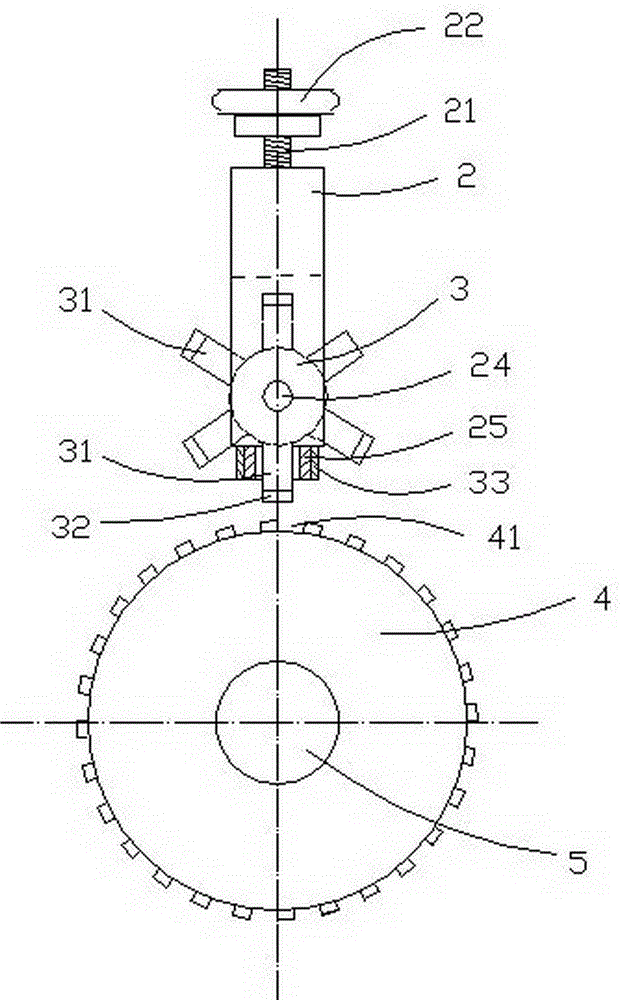

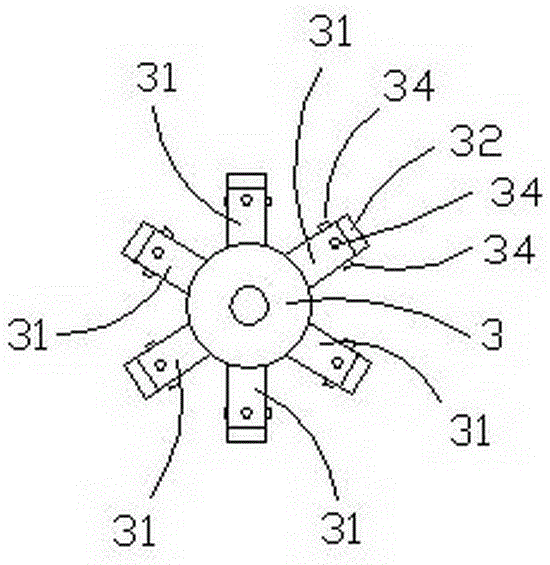

[0012] Such as figure 1 , 2 As shown, a multi-head font includes a support 1, a pillar 2, and a die head 3. The support 1 is provided with a longitudinal seat plate 11, and the pillar 2 is fixed in the guide rail of the seat plate 11 by means of a pressure plate 12 and bolts on the support 1. The top of the pillar 2 is connected to the screw 21, the screw 21 is connected to the handwheel 22, the handwheel 22 adjusts the pillar 2 to move up and down along the guide rail, the lower end of the pillar 2 is an open groove 23, and the die head 3 is rotatably embedded in the open groove 23 by the shaft pin 24 Inside, the lower end of the pillar 2 is a threaded connection part 25, and the locker 33 is screwed with the threaded connection part 25, so that the die head 3 and the pillar 2 are axially fixed to realize the font control work of this unit. The pillar 2 is suspended above the rolling plate 4 for distributing workpieces, and the font 32 of the font control 31 corresponds to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com