Modified starch product mixing and stirring system

A technology of mixing and stirring and modifying starch, which is applied in the direction of mixers, mixer accessories, dissolution, etc., to achieve the effect of ensuring product quality and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

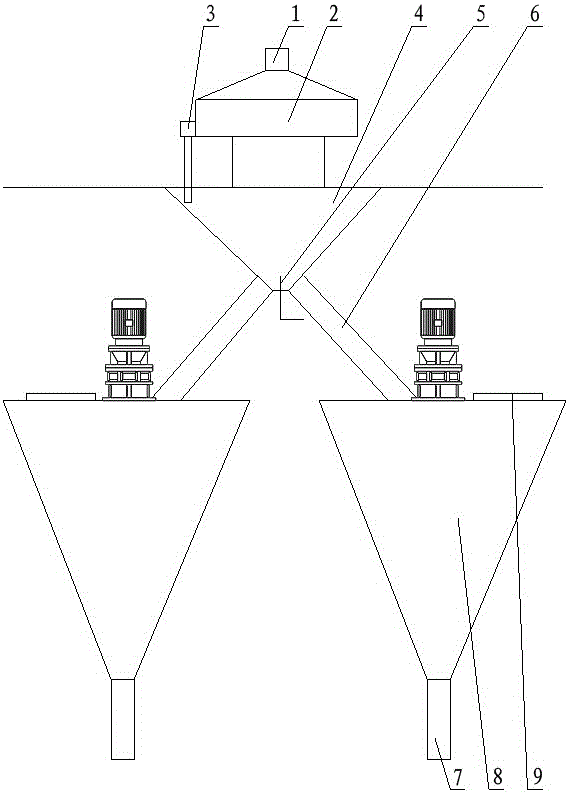

[0014] figure 1 It is a schematic diagram of the structure of the present invention when two-way shunting, such as figure 1 As shown, the modified starch product mixing and stirring system includes a collecting hopper 4, a diverter switch 5, a two-way diverting pipeline 6 and two conical agitators 8, wherein the diverging pipeline 6 is connected to the lower end of the collecting hopper 4, and leads to the respective The opening and closing of the corresponding conical agitator 8 and the two-way shunt pipe 6 is controlled by the shunt switch 5 at the lower end of the collecting hopper 4 . The top of the two conical agitators 8 is provided with a feed inlet 9 and the bottom is provided with a discharge outlet 7 . The two conical agitators 8 have the same suspension height, and the brands and models are the same.

[0015] When in use, the modified starch from the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com