Automatic blister machine

A blister machine, automatic technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as affecting health, organic waste odor, air quality decline, etc., to reduce negative effects, reduce pollution, The effect of reducing the frequency of manual replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

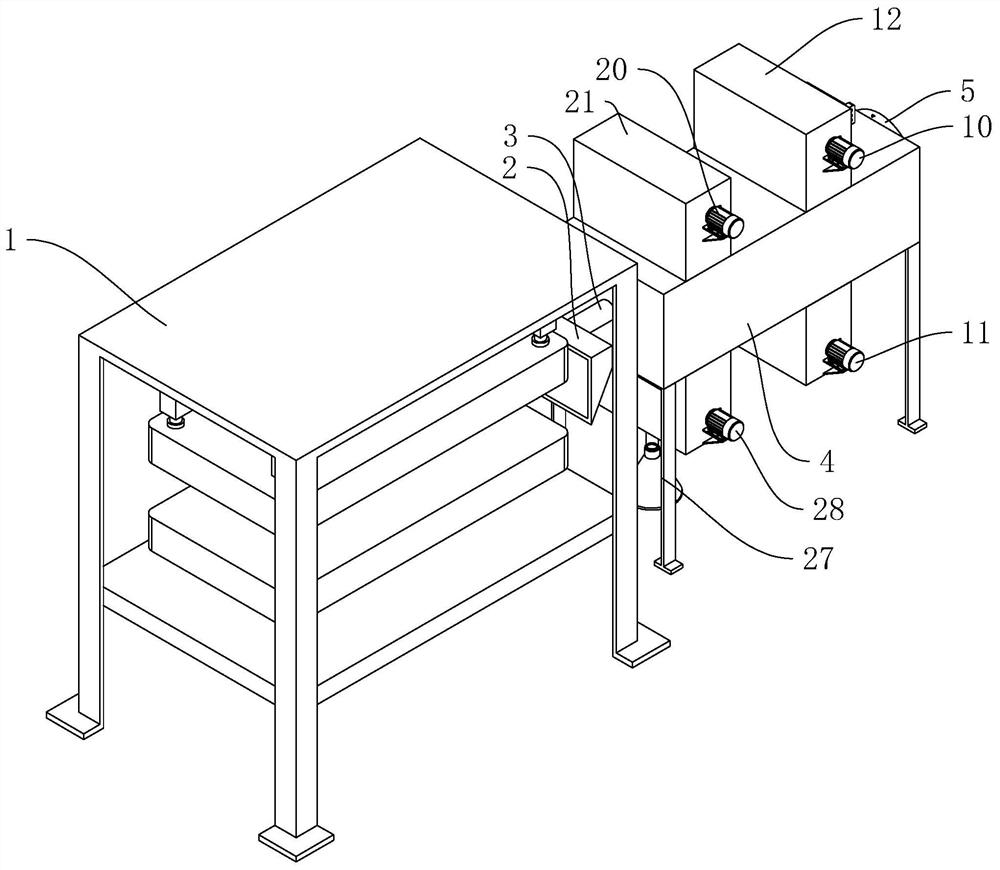

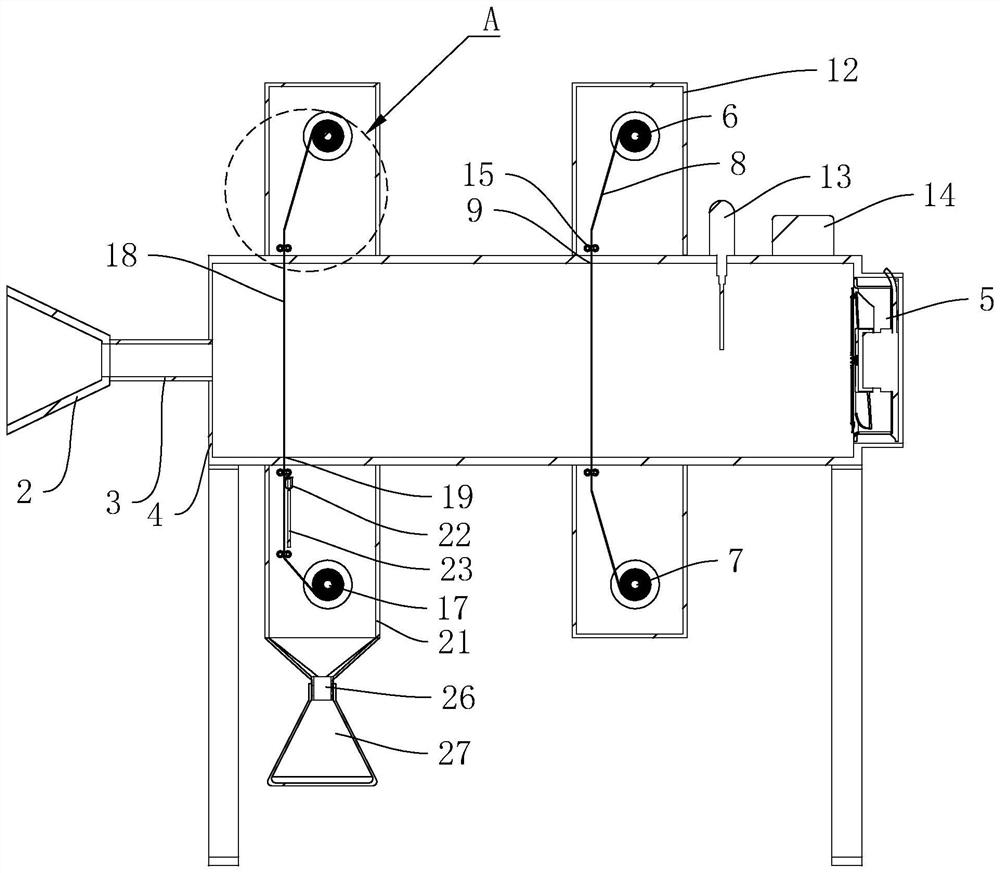

[0036] refer to figure 1 and figure 2 , is an automatic plastic suction machine disclosed in the present invention, comprising a plastic suction machine body 1, a suction hood 2 is arranged on one side of the plastic suction machine body 1, and a suction hood 2 is connected to a side away from the plastic suction machine body 1 The suction pipe 3 is connected to a waste gas treatment box 4 on the side far away from the suction hood 2 , and a suction fan 5 is provided on the end of the waste gas treatment box 4 away from the suction pipe 3 .

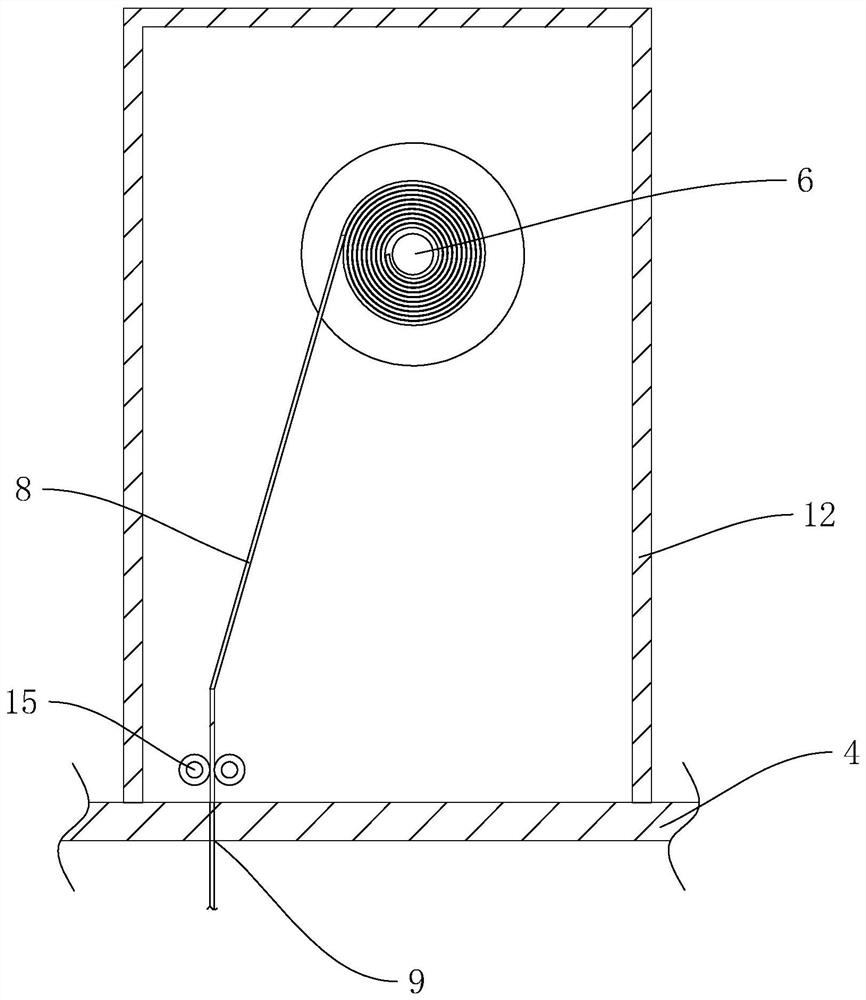

[0037] refer to figure 2 and image 3 , in order to purify the organic waste gas, the top and bottom of the exhaust gas treatment box 4 are respectively provided with a main winding roll 6 and a secondary winding roll 7, and a protective cover 12 is arranged around the main winding roll 6 and the secondary winding rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com