Complete sets for continuous synthesis of phenyl chlorosilane

A technology of phenylchlorosilane and complete sets of equipment, which is applied in the field of complete sets of equipment for the continuous synthesis of phenylchlorosilane, can solve the problems of a single temperature zone of the reaction device, etc., and achieve long service life, high synthesis efficiency and short synthesis route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

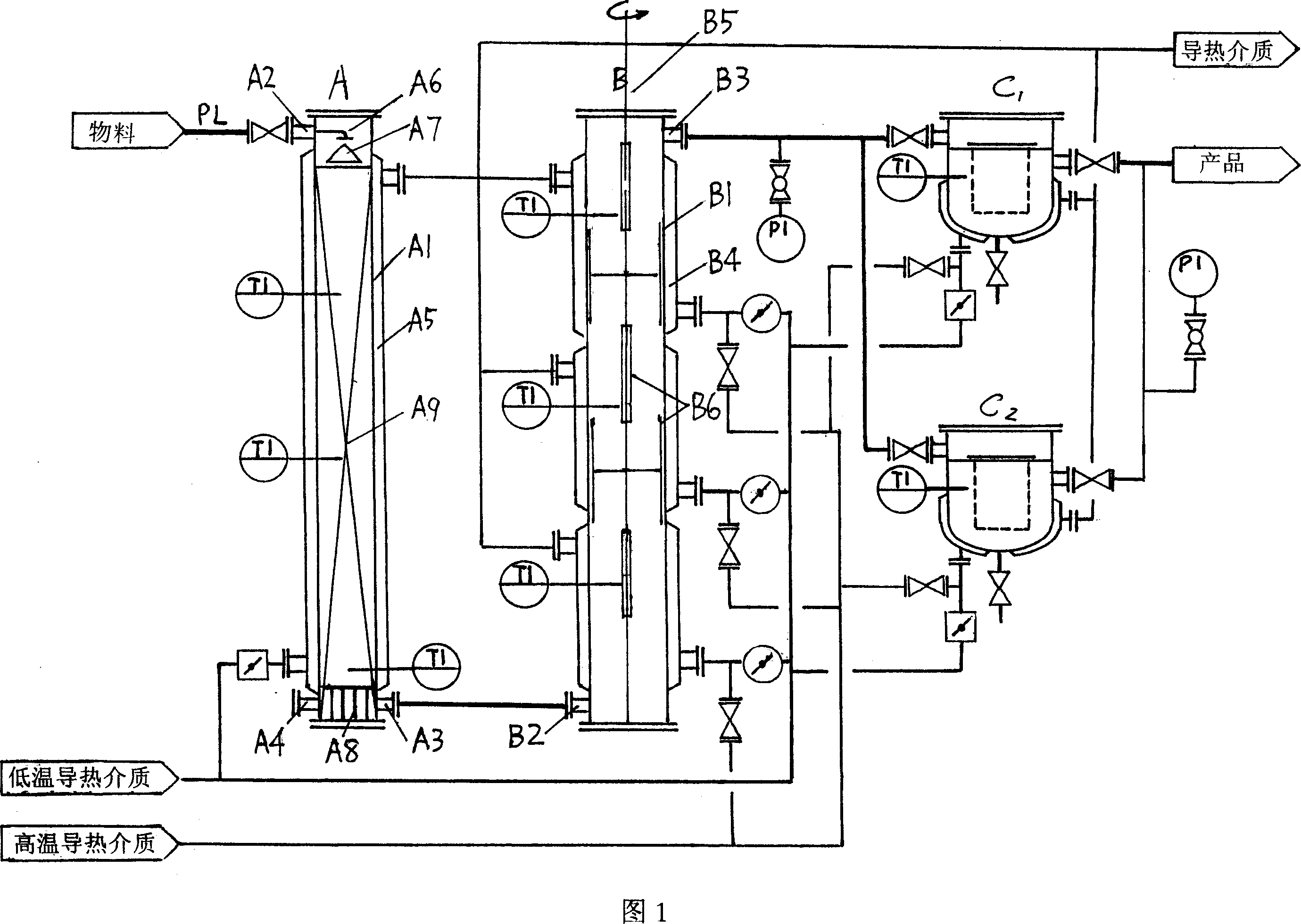

[0036] Example. See Fig. 1, the complete set of chemical equipment for the continuous method synthesis of phenylchlorosilane of the present invention is composed of an acid-resistant preheating device A, a tubular reaction device B and a filter purification device C connected in series; the outlet A3 of the acid-resistant preheating device is connected to the pipe The lower inlet B2 of the reaction device is connected, and the upper outlet B3 of the reaction device is connected in parallel with the filter and purification device C—two multi-basket pipeline filters C1 and C2. The jackets of the three devices are all in communication with the low thermal conductivity medium source (molten salt) at 190-200° C. according to the prior art.

[0037] The material of the main equipment is required to be stable to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com