Vertical roll grinder grinding disc material layer stabilizing device and vertical roll grinder

A vertical roller mill with stable material layer technology, applied in grain processing, etc., can solve the problems of ineffective use, not suitable for promotion, high degree of wear, etc., and achieve the effects of simple structure, stable production, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the details are as follows:

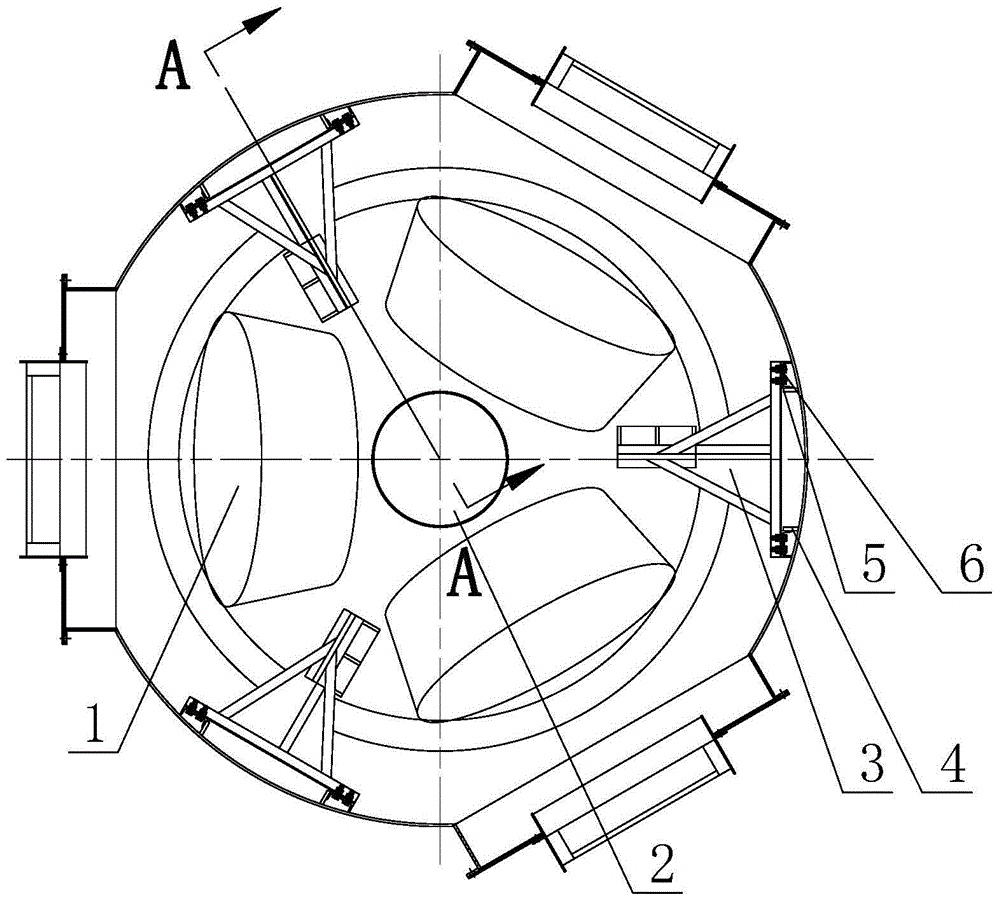

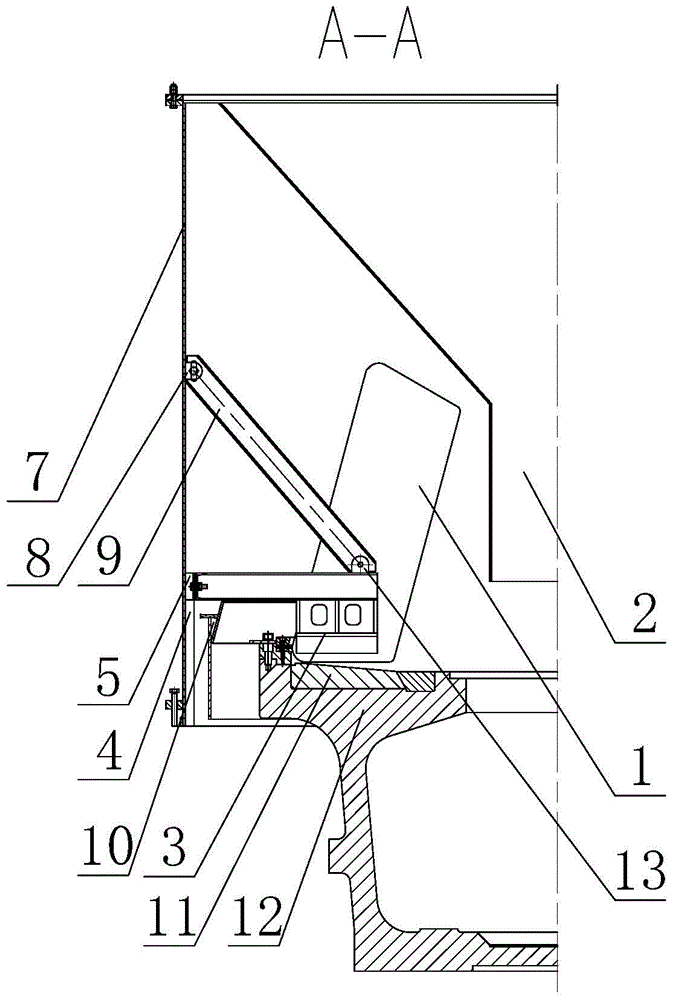

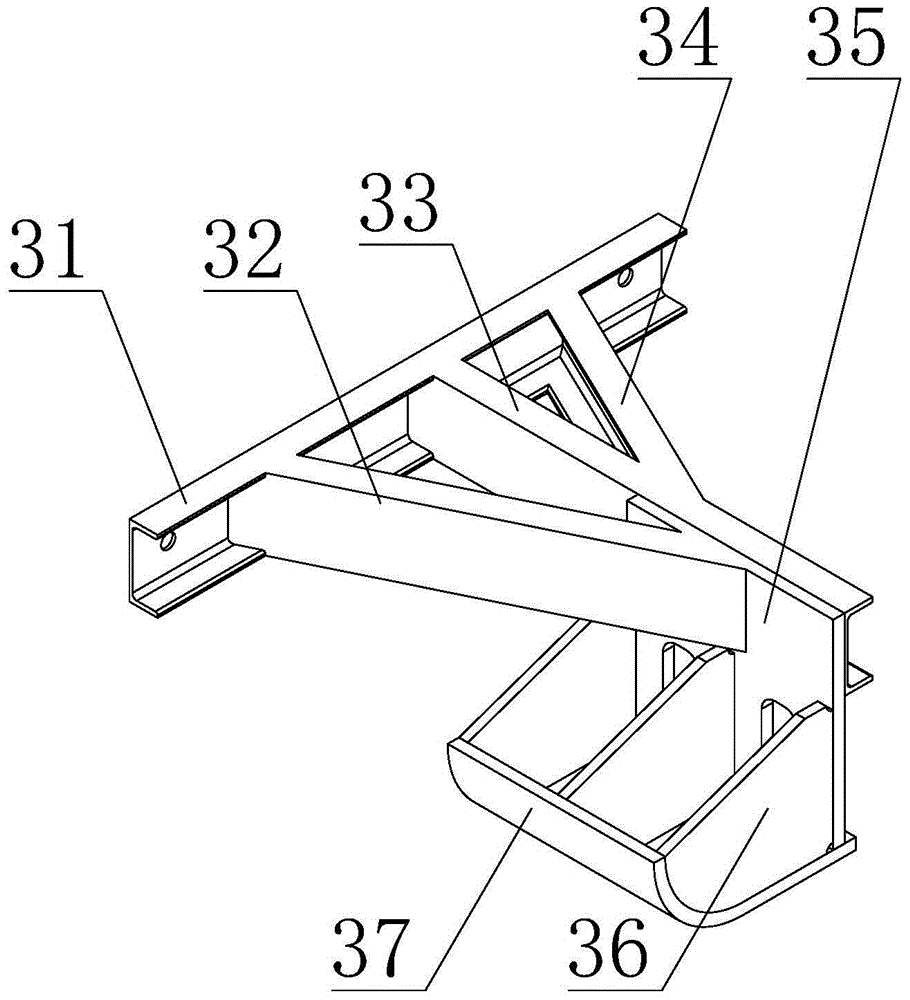

[0020] like figure 1 As shown, a vertical roller mill comprises a grinding disc 12, a middle casing 7, a grinding roller 1, a central feeding chute 2 and a vertical roller mill grinding disc material layer stabilizing device, and a grinding disc liner 11 is installed on the grinding disc. The material bed stabilization device of the type roller mill includes a support plate 4 welded on the middle shell, and the support plate 4 is arranged along the axis direction of the middle shell 7 and is arranged on the inner side of the middle shell 7 . The supporting plate 4 is welded with a connecting channel armor 5 with long holes, which is also parallel to the axial direction of the middle shell 7, and the inner side of the connecting channel armor 5 is provided with a reinforcing plate 6 to impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com