Manufacturing device and manufacturing method of ball mill steel ball

A technology for manufacturing equipment and manufacturing methods, applied in manufacturing tools, heat treatment equipment, metal processing equipment, etc., can solve problems such as large temperature differences, poor product performance consistency, and difficulty in achieving complete temperature uniformity. The effect of improving the performance of steel balls, eliminating lattice defects and internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

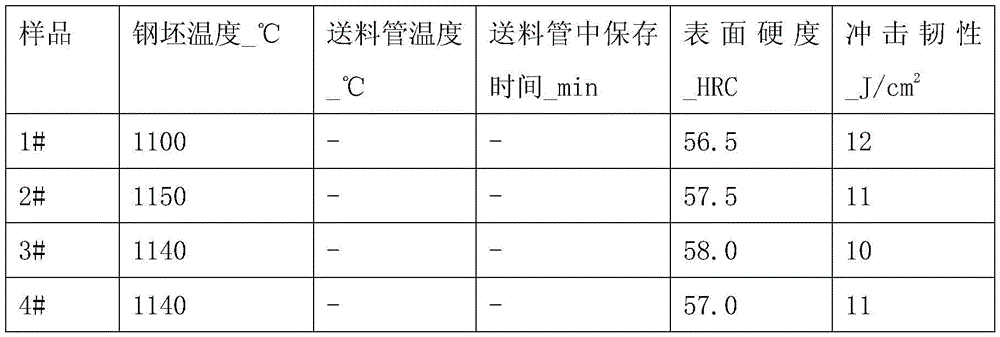

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

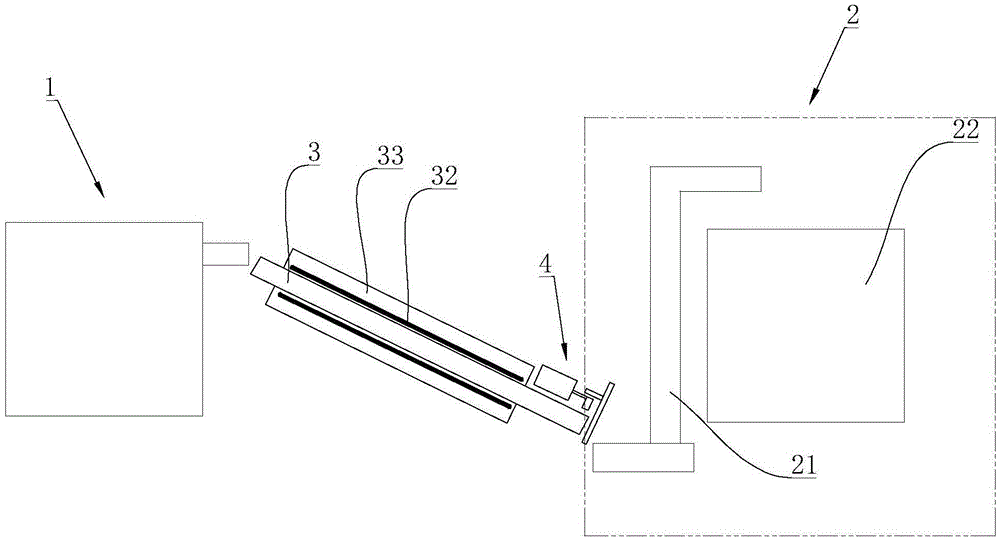

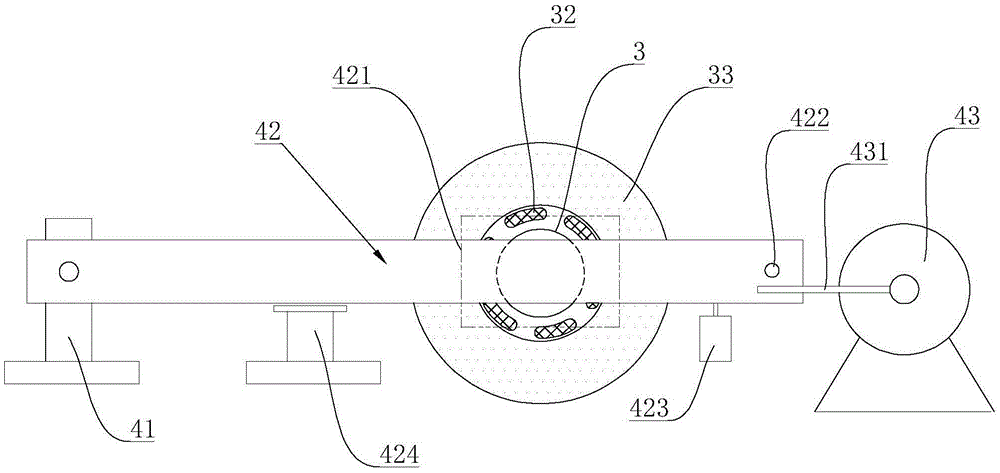

[0031] The ball mill steel ball manufacturing equipment includes a forging machine 1 and a quenching device 2, and also includes a feeding pipe 3. The inside and / or outside of the feeding pipe 3 is provided with an insulating layer 33, and the inlet of the feeding pipe 3 is connected to the outlet of the forging machine 1. At the feed end, the outlet of the feed pipe 3 is connected to the feed end of the quenching device 2 , and the inlet of the feed pipe 3 is higher than the outlet of the feed pipe 3 .

[0032] Steel ball manufacturing equipment of the present invention replaces the V-shaped groove of traditional equipment with feed pipe 3, as figure 1 As shown, the feeding pipe 3 is located between the forging machine 1 and the quenching device 2, and the high-temperature steel balls sent out by the forging machine 1 can roll down from the inside of the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com