Continuous type mixing station stock bin with online sampling device and sampling method

A sampling device and silo technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of potential safety hazards, segregation of mixed materials, difficulty in obtaining representative samples, etc., to save manpower and material resources, representative Good, simple and fast sampling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

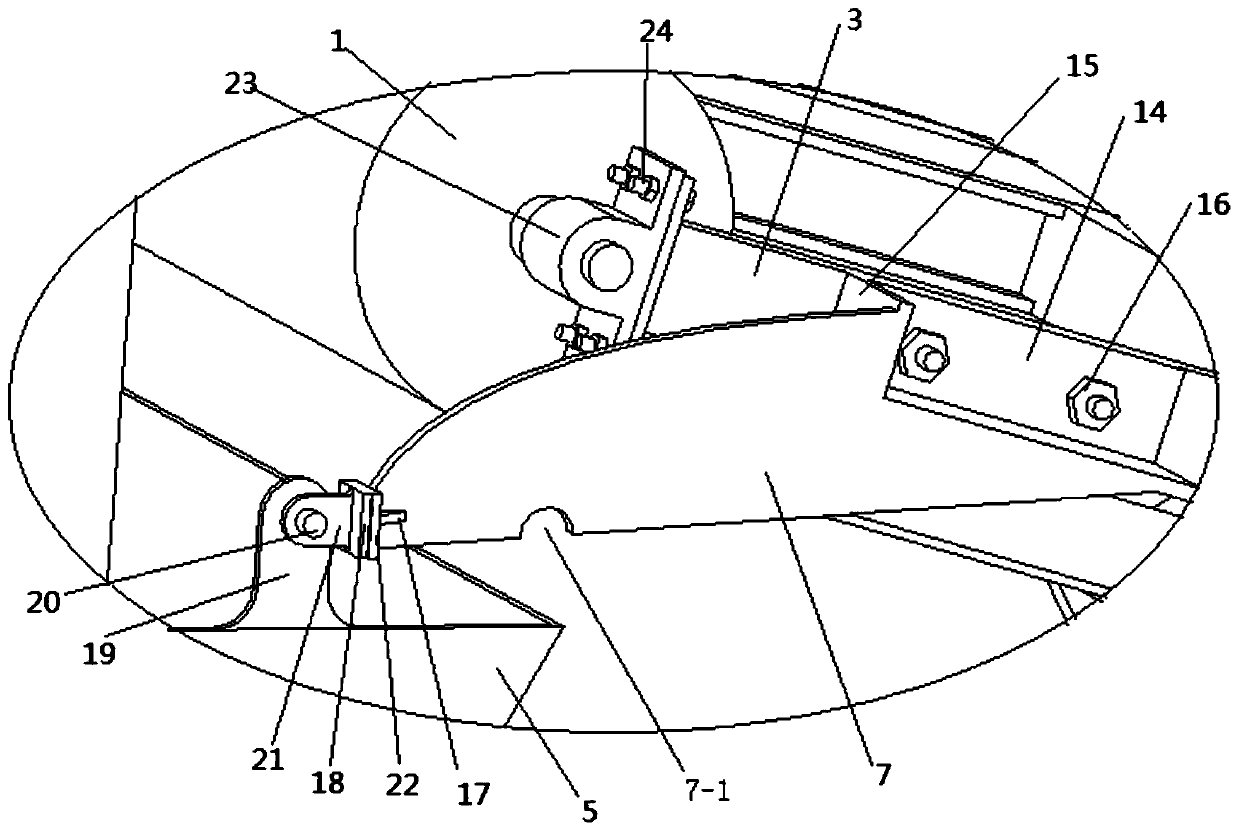

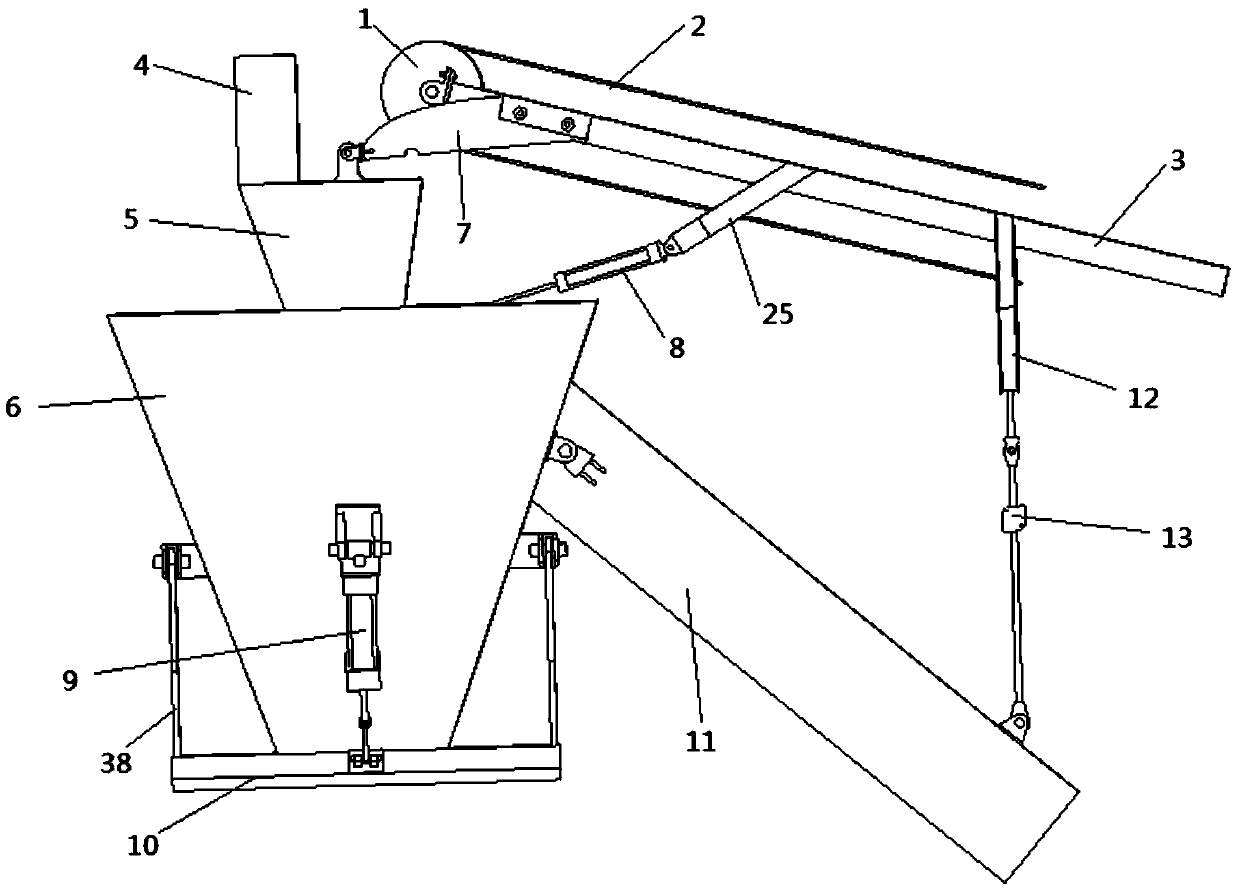

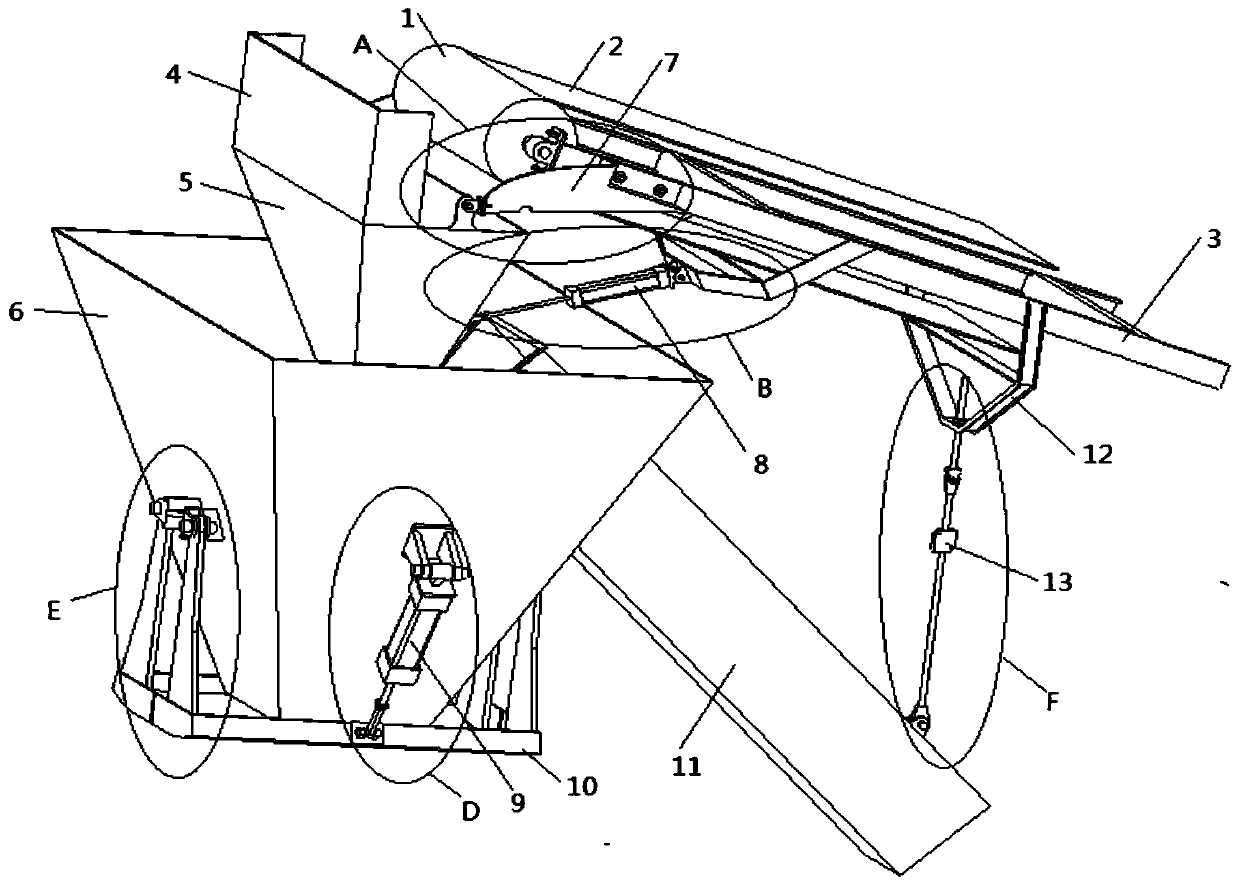

[0052] Such as figure 1 , figure 2 and Figure 8 As shown, the continuous mixing station silo configured with an online sampling device in this embodiment includes a hopper 5 above the finished product silo 6 and a material guide pipe 11 that passes through the side wall of the finished product silo 6 and is placed obliquely. The hopper 5 Hinged with hanging beam 7, said hanging beam 7 is installed on both sides of the end (discharging end) of conveyor belt frame 3, two hanging beams 7 are connected with conveyor belt frame 3 by bolts, said conveyor belt frame 3 is equipped with drag bucket cylinder 8 , the extension rod 32 of the drag bucket cylinder 8 is connected to the guide hopper 5 through a hinge, the finished product warehouse 6 is installed directly below the guide hopper 5, and the material door 10 and the sliding door cylinder 9 are installed on both sides of the finished product warehouse 6 , the extension rod 47 of the sliding door cylinder 9 is hinged with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com