Multi-head automatic printing machine

A printer and automatic technology, applied in printing, stamping, etc., can solve problems such as slow processing speed, inconvenient adjustment, structural defects, etc., and achieve the effects of fast conversion speed, convenient operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

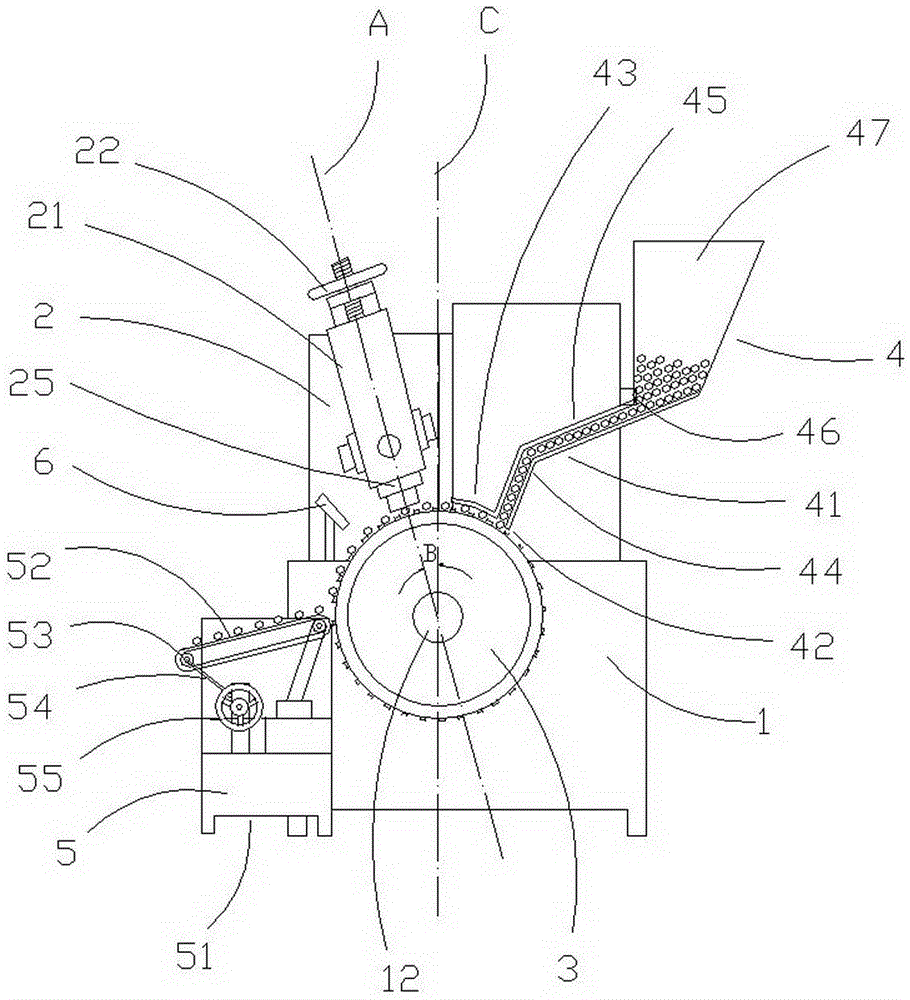

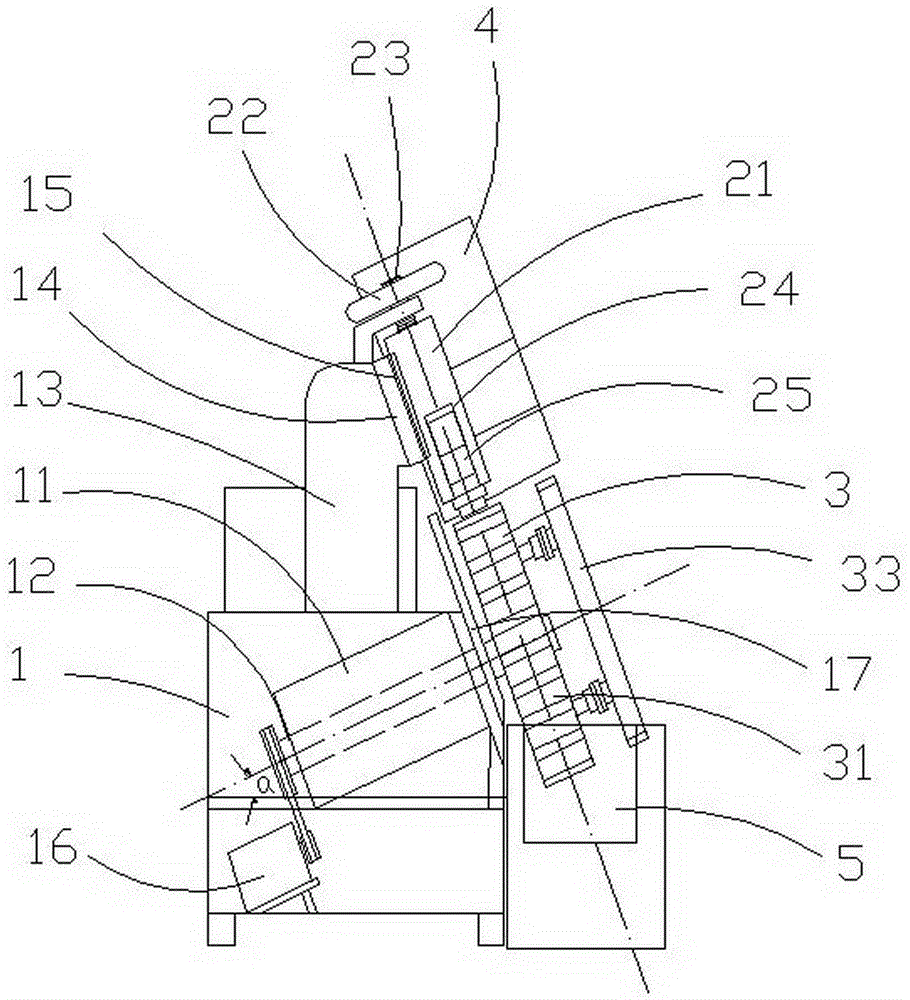

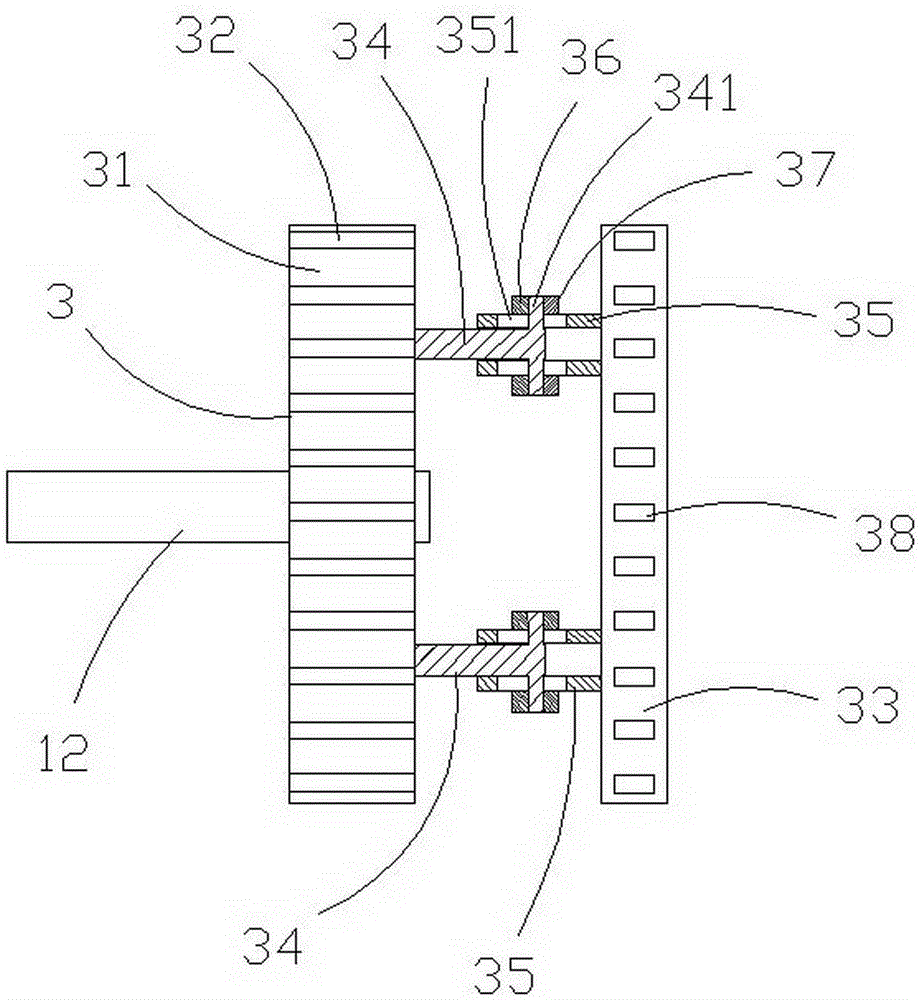

[0021] like figure 1 , 2 , 3, shown in 6, a kind of multi-head automatic printer, comprises frame 1, printing mechanism 2, feeding turntable 3, input mechanism 4, output mechanism 5, frame 1 side fixed spindle box 11, and spindle box 11 is obliquely equipped with Form the main shaft 12 of 30 ° angle α with the plane of the fuselage, and the main shaft 12 is driven by the variable speed motor 16 to rotate. The feed turntable 3 is connected to the main shaft 12 to form an inclined shape. A baffle plate 17 that can axially adjust the printing part of the circular workpiece is arranged between the headstock 11 and the feed turntable 3 . The outer side of the feed turntable 3 is connected to a support ring 33 . When the circular workpiece enters the rolling groove 31 of the feeding turntable 3, one end of the circular workpiece automatically slides to the baffle plate 17, so that the printing part of the circular workpiece is uniformly positioned. According to the printing positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com