Preparation method of transparent conductive thin film with grating structure

A technology of transparent conductive film and grating structure, applied to the conductive layer on the insulating carrier, ion implantation plating, coating, etc., can solve the problems of long preparation time period, uneven product shape and size, complicated operation process, etc. , to achieve the effects of reducing environmental pollution and personal safety hazards, short sample preparation time, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

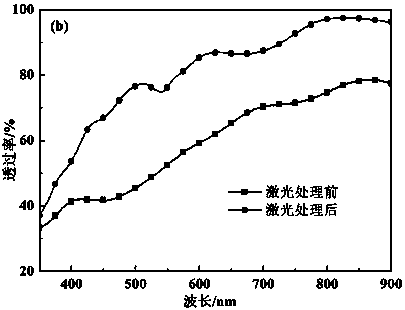

[0018] Preparation of Ag / FTO transparent conductive film: directly use commercially available FTO glass (thickness 750 nm, average transmittance 80%, sheet resistance 8.5 Ω / sq) as the substrate, use the method of cleaning the glass substrate, wash and dry, and then use The Ag layer was sputtered by a high-vacuum DC magnetron sputtering device (the purity of the Ag target is 99.99%), the sputtering current was 60 mA, the sputtering time was 3 seconds, and the sputtering gas was argon, and metal Ag was deposited on the FTO glass substrate On the film, obtain the Ag / FTO transparent conductive film for subsequent use.

[0019] The Ag / FTO transparent conductive film grating structure is to scan the Ag / FTO transparent conductive film with a nanosecond laser with a pulse width of 1-2 ns, a wavelength of 532 nm, and a repetition rate of 1 kHz. The method is as follows: adjust the position of the sample stage so that the surface of the Ag / FTO transparent conductive film is located 2.5 ...

Embodiment 2

[0021] Preparation of Pt / FTO transparent conductive film: directly use commercially available FTO glass (thickness about 750 nm, average transmittance 80%, sheet resistance 8.5 Ω / sq) as the substrate, use the method of cleaning the glass substrate, after cleaning and drying, and then The Pt layer was sputtered by a high-vacuum DC magnetron sputtering apparatus (the purity of the Pt target was 99.99%), the sputtering current was 60 mA, the sputtering time was 4 seconds, and the sputtering gas was argon. Deposit the metal Pt layer on the FTO glass base film.

[0022] The Pt / FTO transparent conductive film grating structure is to scan the Pt / FTO transparent conductive film with a nanosecond laser with a pulse width of 1-2 ns, a wavelength of 532 nm, and a repetition rate of 1 KHz. The method is as follows: adjust the position of the sample stage so that the surface of the Pt / FTO transparent conductive film is located 2.5 mm behind the laser focus; control the laser energy density...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com