Drawing forming device and method of rotary part

A technology of rotary body and parts, applied in the field of deep drawing forming method and device of rotary body parts, can solve the problems of high qualified rate of metal thin-walled rotary body parts, prone to cracking and wrinkling, etc., so as to avoid local wrinkling, The effect of ensuring forming quality and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment of the present invention provides a method and device for deep-drawing and forming of rotary parts, which solves the technical problems in the prior art that the metal thin-walled rotary parts are prone to defects such as cracking, wrinkling, and scratches during the deep-drawing process. , Realize the one-time deep drawing forming of metal thin-walled rotary parts, and the qualified rate of formed metal thin-walled rotary parts is high.

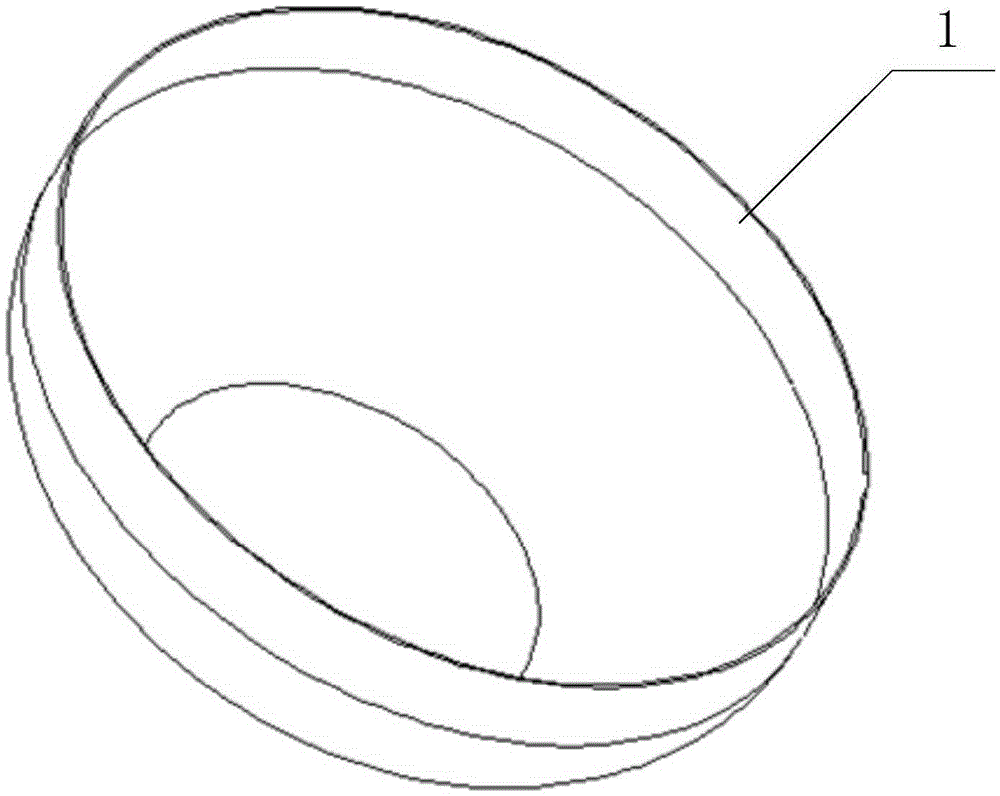

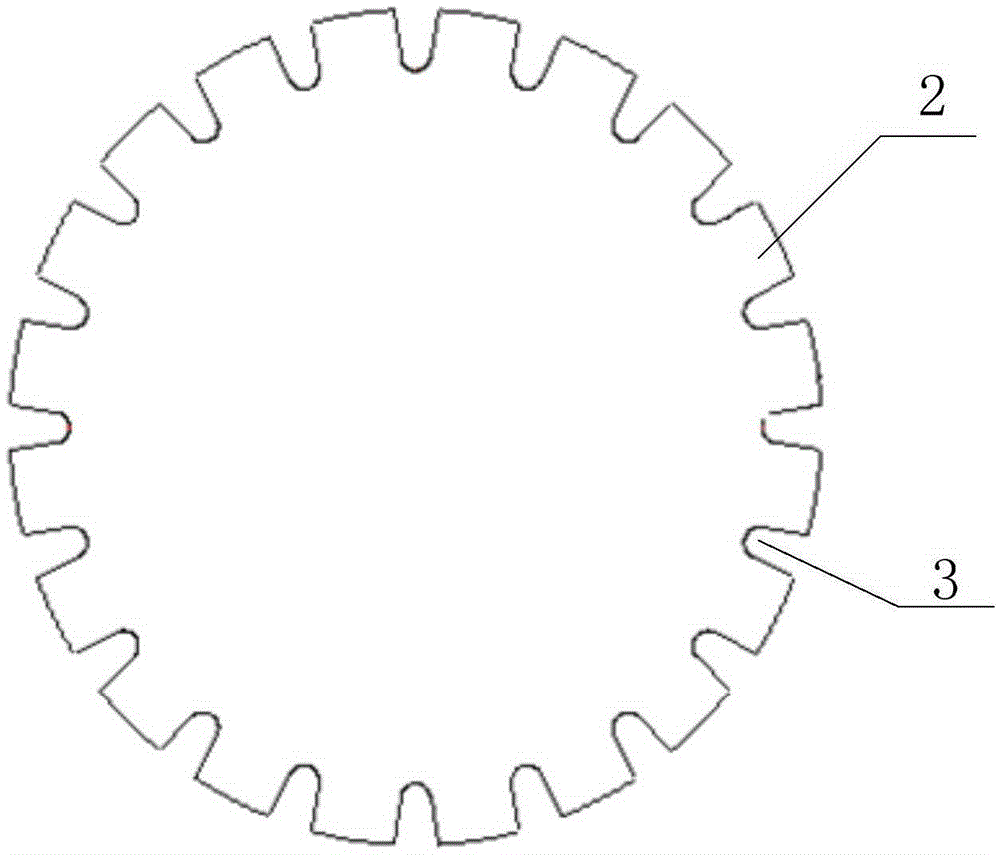

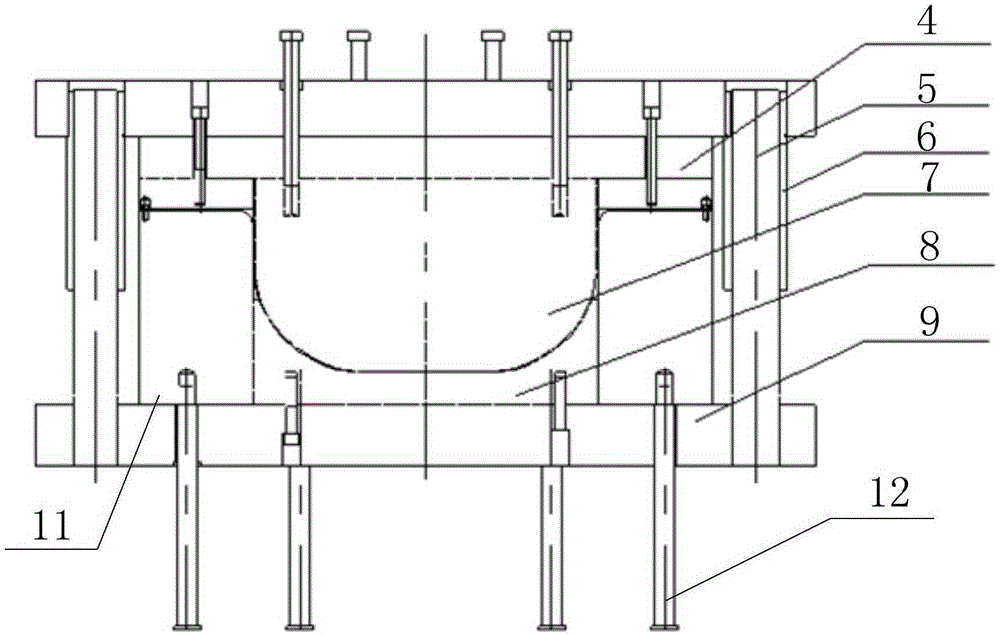

[0031] see Figure 1 ~ Figure 4 , the embodiment of the present invention provides a rotary part deep drawing device, the device is used to process the blank 2 into a rotary part 1, and the thinnest wall thickness of the processed rotary part 1 is required to be greater than 0.8mm. The deep-drawing device for rotary parts provided by the embodiment of the present invention includes: an upper combination die 4, a punch 7, a die 8, a die frame 11, a lower die 9, a guide post 5, a guide sleeve 6, a ejector rod 12 and an ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com