Destressing method and device for amorphous alloy transformer iron core

A technology of transformer iron core and amorphous alloy, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. loss, good annealing effect, low no-load loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

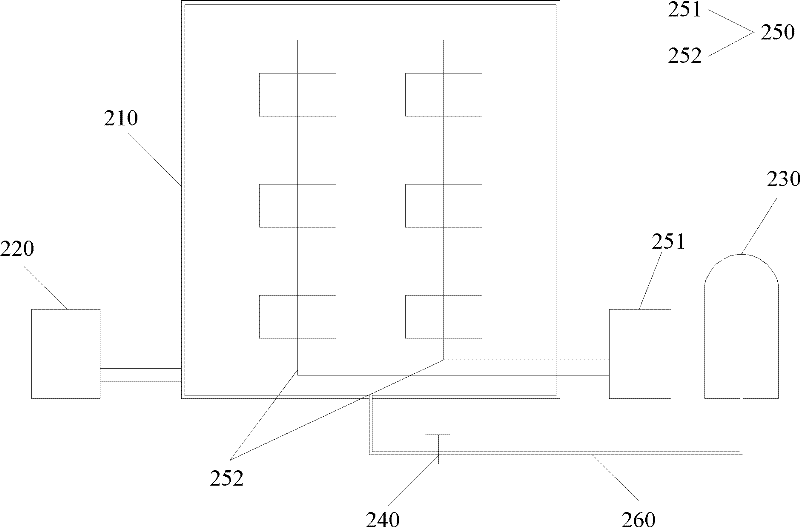

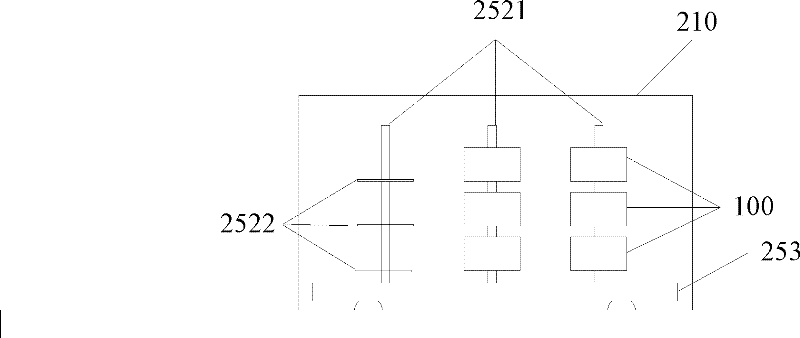

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, exemplary embodiments are given below together with accompanying drawings and described in detail as follows.

[0034] The invention fully considers the negative impact of vacuum treatment on the stress relief treatment of the amorphous iron core and the expense of equipment costs. pressure to prevent air from entering and oxidizing the iron core; meanwhile, the present invention fully considers that the amorphous alloy material is sensitive to temperature and time during annealing, and controls the heat preservation temperature of the iron core in a narrower temperature and time range below the Curie temperature In order to achieve the best annealing effect, the amorphous core maintains the advantage of low no-load loss.

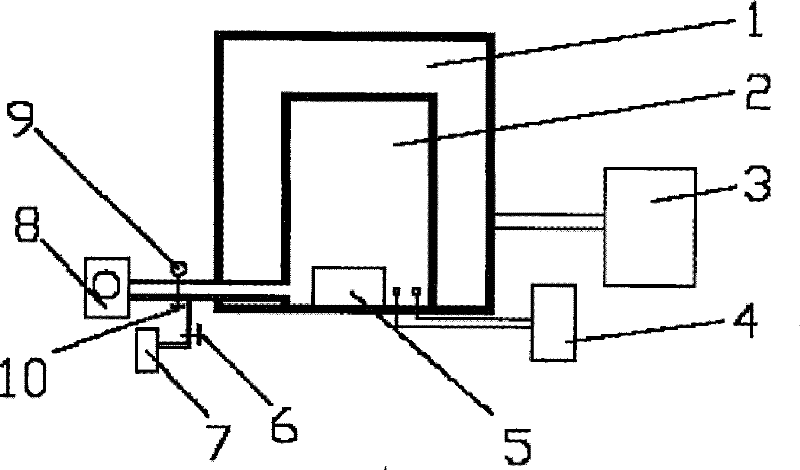

[0035] For details, please refer to figure 2 , which is a structural schematic diagram of an amorphous alloy transformer core stress relief d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com