Annealing technique of cast polycrystalline silicon

An annealing process, polysilicon technology, applied in the direction of polycrystalline material growth, crystal growth, post-processing details, etc., can solve the problems of no mass production practicability, no obvious advantages in cost control, no obvious contribution to product quality, etc., to achieve enhanced Effect of annealing, reduction of annealing temperature and time, effect of thermal stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

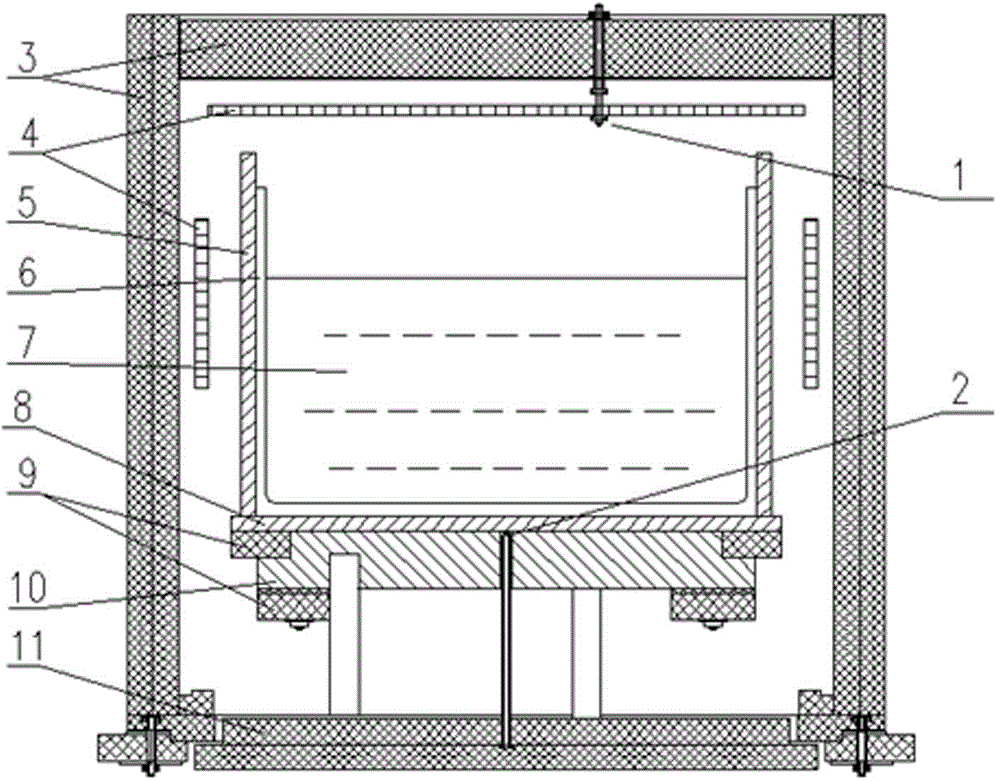

Image

Examples

Embodiment 1

[0022] The embodiment of the present invention provides an annealing process for polysilicon ingots. The annealing process uses a G5 type ingot furnace to cast polysilicon ingots. A G5 quartz crucible is selected, and the charge weight is 500Kg. Ingot process, the annealing process is performed after the crystal growth process is completed. In the first step of the annealing stage, set the temperature control mode, and use 90 minutes to reduce the temperature in the crucible from 1410 ° C to 1250 ° C, and at the same time move the heat insulation cage from the position of 20 cm to the position of 8 cm. After the first step of annealing is completed, the temperature inside the crucible reaches 1250°C, and the temperature at the bottom of the crucible reaches 1000°C. In the second step of the annealing stage, set the temperature control mode, and use 20 minutes to reduce the temperature in the crucible from 1250°C to 1200°C, and at the same time move the heat insulation cage fro...

Embodiment 2

[0025] The embodiment of the present invention provides an annealing process for polysilicon ingots. The annealing process uses a G5 type ingot furnace for high-efficiency polysilicon ingots. A G5 quartz crucible is selected, and the charge weight is 600Kg. Ingot casting process, the annealing process is performed after the crystal growth process is completed. In the annealing step, set the temperature control mode, use 180 minutes to reduce the temperature in the crucible from 1390 °C to 920 °C, and set the moving speed of the heat insulation cage to 6 cm / h. At the end of the annealing, the temperature inside the crucible reaches 920°C, the temperature at the bottom of the crucible reaches 900°C, and the cooling procedure is entered.

[0026] After calculation and verification, the running time of polycrystalline silicon ingots is shortened by 3 hours compared with the normal process, and the electricity cost is saved by 300Kw h. The obtained polycrystalline silicon ingots pa...

Embodiment 3

[0028] The embodiment of the present invention provides an annealing process for polysilicon ingots. The annealing process uses a G6 type ingot furnace for similar monocrystalline silicon ingots. A G6 quartz crucible is selected, and the charge weight is 800Kg, which is sent into the ingot furnace and vacuumized. Finally, the ingot casting process is run, and the annealing process is performed after the crystal growth program is completed. In the first step of the annealing stage, set the temperature control mode, and use 90 minutes to reduce the temperature in the crucible from 1400°C to 1200°C, and at the same time move the heat insulation bottom plate from the 24cm position to the 2cm position. In the second step of the annealing stage, set the power control mode, use 120 minutes to reduce the temperature from 1200 ° C to 950 ° C, and at the same time move the heat insulation cage from the position of 2 cm to the position of 10 cm. After the second step of annealing is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com