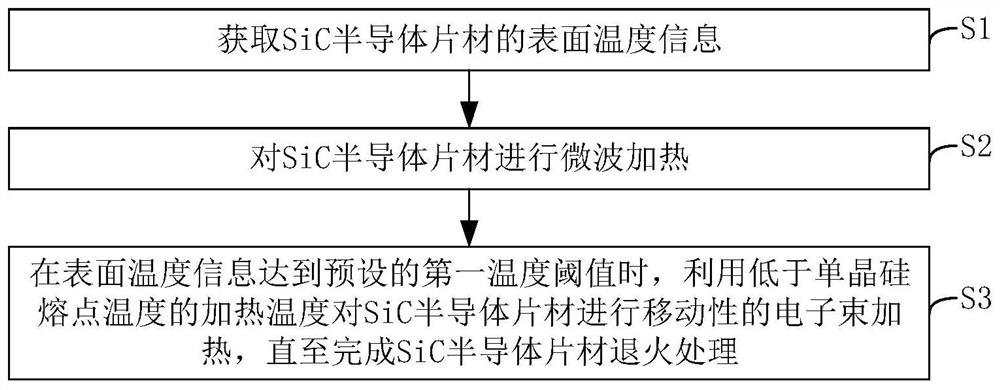

Semiconductor annealing method, annealing device and annealing system

An annealing device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, crystal growth, etc., can solve problems such as damage and reduction of surface elements or protective layers, improve annealing treatment efficiency, and reduce annealing treatment temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

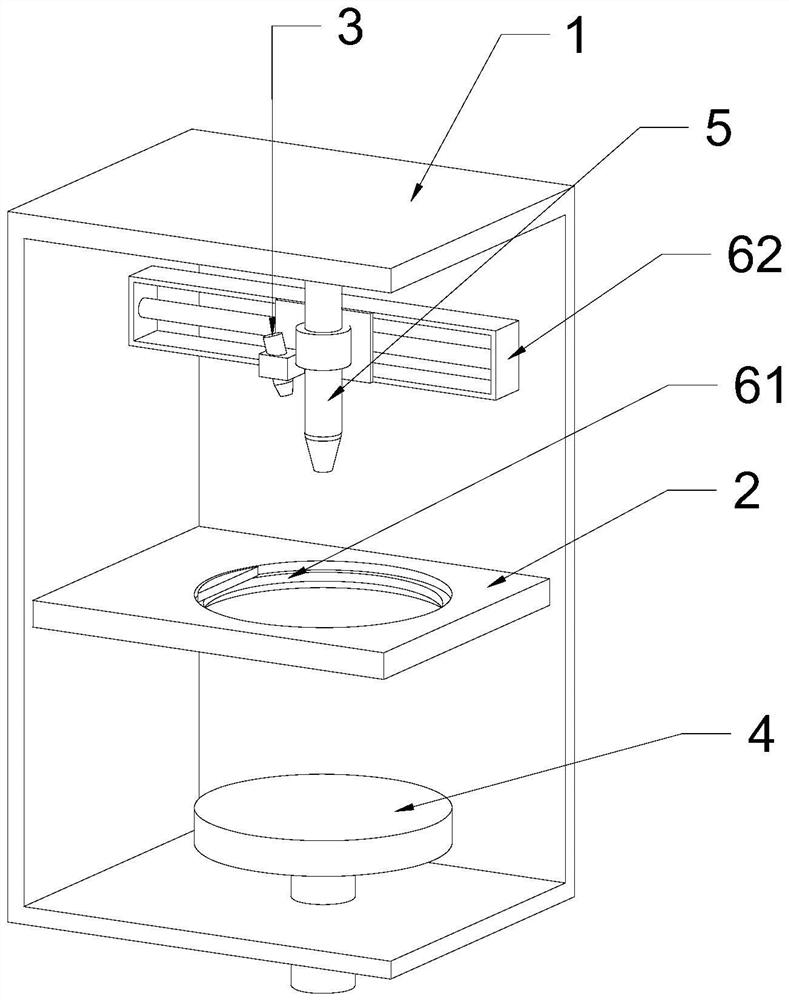

[0136] In order to more clearly illustrate the embodiments of the present application, Image 6 The semiconductor annealing apparatus shown anneals the SiC semiconductor sheet (hereinafter referred to as SiC sheet) produced by ion implantation of SiC, and the process is as follows:

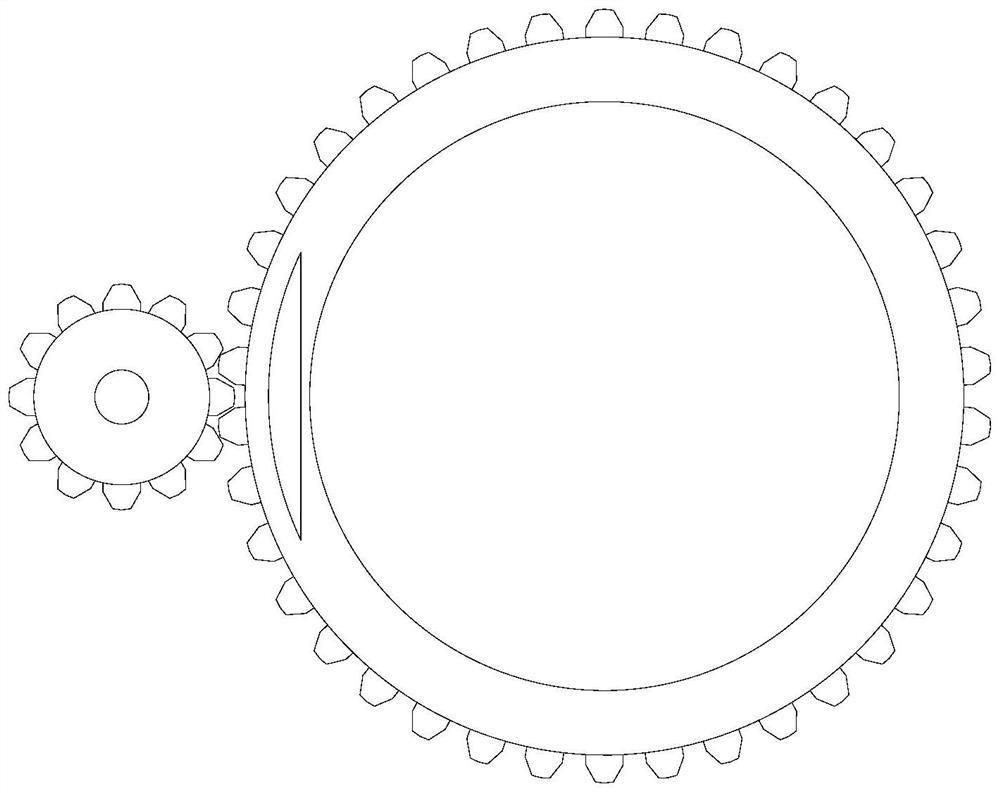

[0137] After both the loading chamber 7 and the annealing chamber 1 are filled with protective gas, the SiC chip is moved to the supporting mechanism 2 by the loading and unloading manipulator 8, and the controller 9 controls the first rotating component 61 and the microwave heating mechanism 4 to start, so that the SiC chip is activated Continue to rotate, and use the microwave heating mechanism 4 to microwave the SiC sheet. The microwave frequency of the microwave heating mechanism 4 is 2.45 GHz. The ion implantation type, ion implantation degree and thickness of the SiC sheet will affect the efficiency of microwave heating.

[0138] During the microwave heating process, the surface temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com