Conveying walking device for annealing processing of semiconductor electronic device

A technology of electronic devices and walking devices, which is applied in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., can solve the problems of intermittent material transportation, energy waste, and affecting the efficiency of semiconductor annealing treatment, etc. Effect of annealing treatment, reduced energy consumption, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

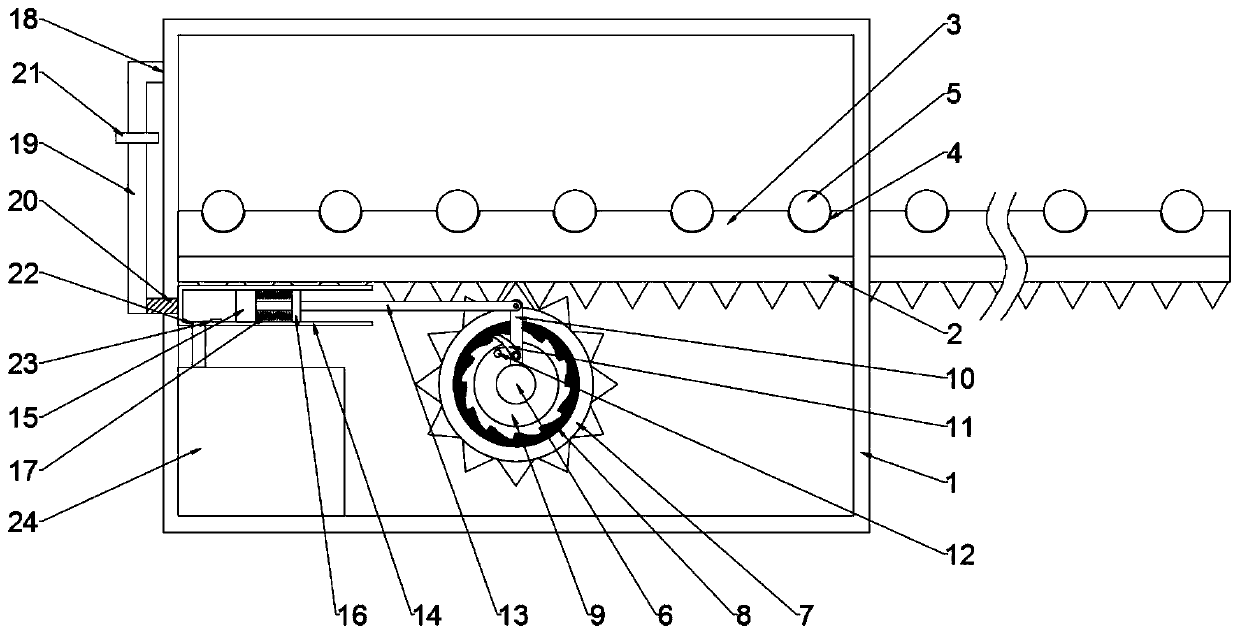

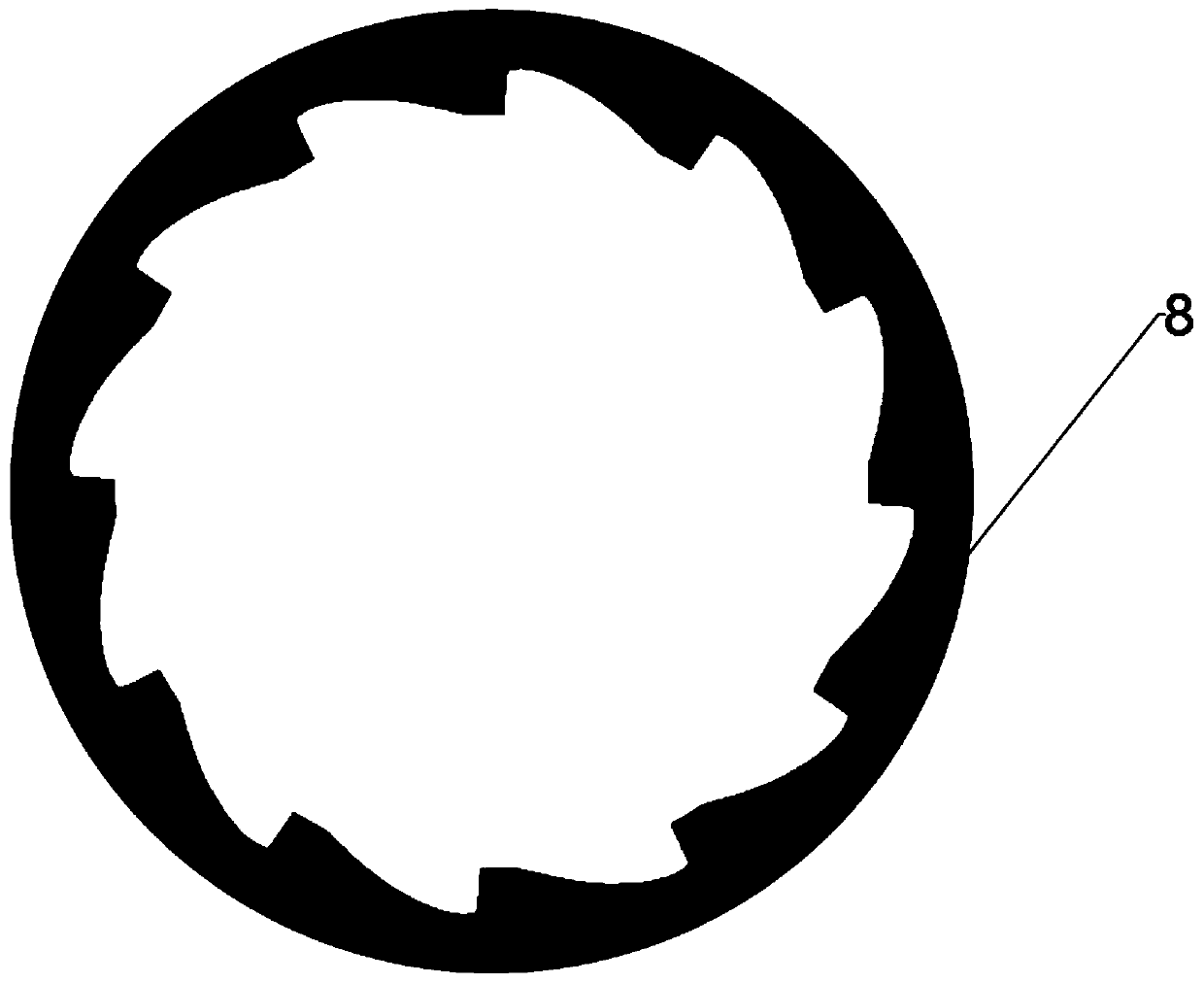

Embodiment 1

[0036] see Figure 1-2 , a kind of conveying and walking device for the annealing processing of semiconductor electronic devices, comprising a furnace body shell 1, an annealing mechanism is arranged inside the furnace body shell 1, support plates are fixed on the inner walls of the front and rear sides of the furnace body shell 1, and the support plates are slidably connected There is a tooth plate 2, a semiconductor tube placement groove 3 is fixed on the tooth plate 2, a plurality of teeth are integrally formed on the lower surface of the tooth plate 2, and a plurality of semicircular grooves 4 are placed on the semiconductor tube placement groove 3, the furnace The inner walls of the front and rear sides of the body shell 1 are plugged with a rotating shaft 6, the rotating shaft 6 is horizontally arranged and perpendicular to the tooth plate 2, and the outer wall of the rotating shaft 6 is located below the teeth and is connected with an external gear 7 for rotation. Engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com