Automobile part machining device and using method thereof

A technology of auto parts and processing equipment, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems that the annealing furnace cannot guarantee the uniformity of the temperature of the working chamber, affect the effect of annealing, and uneven heating, etc., so as to improve the annealing effect , less heat loss, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

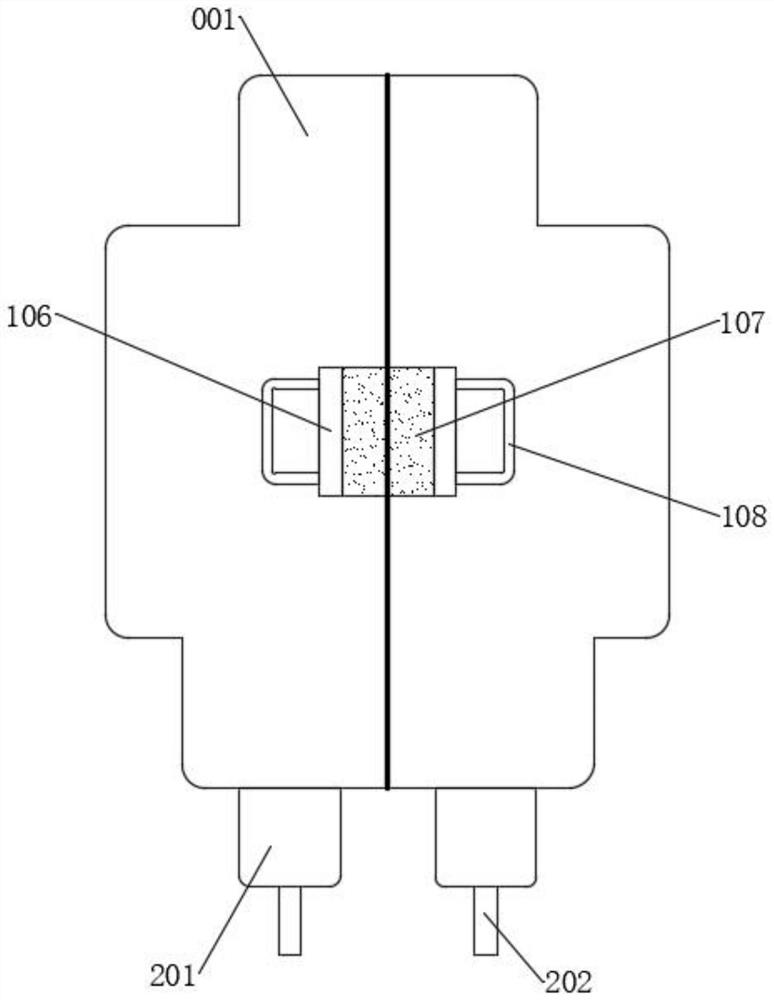

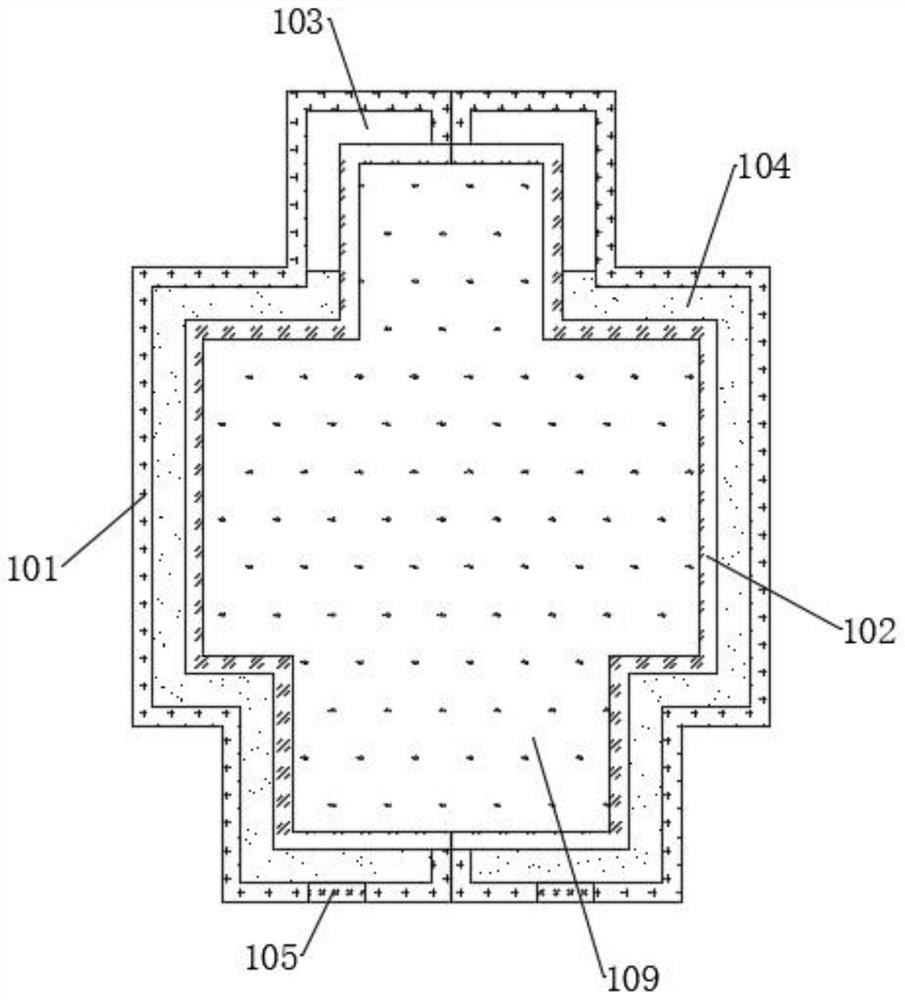

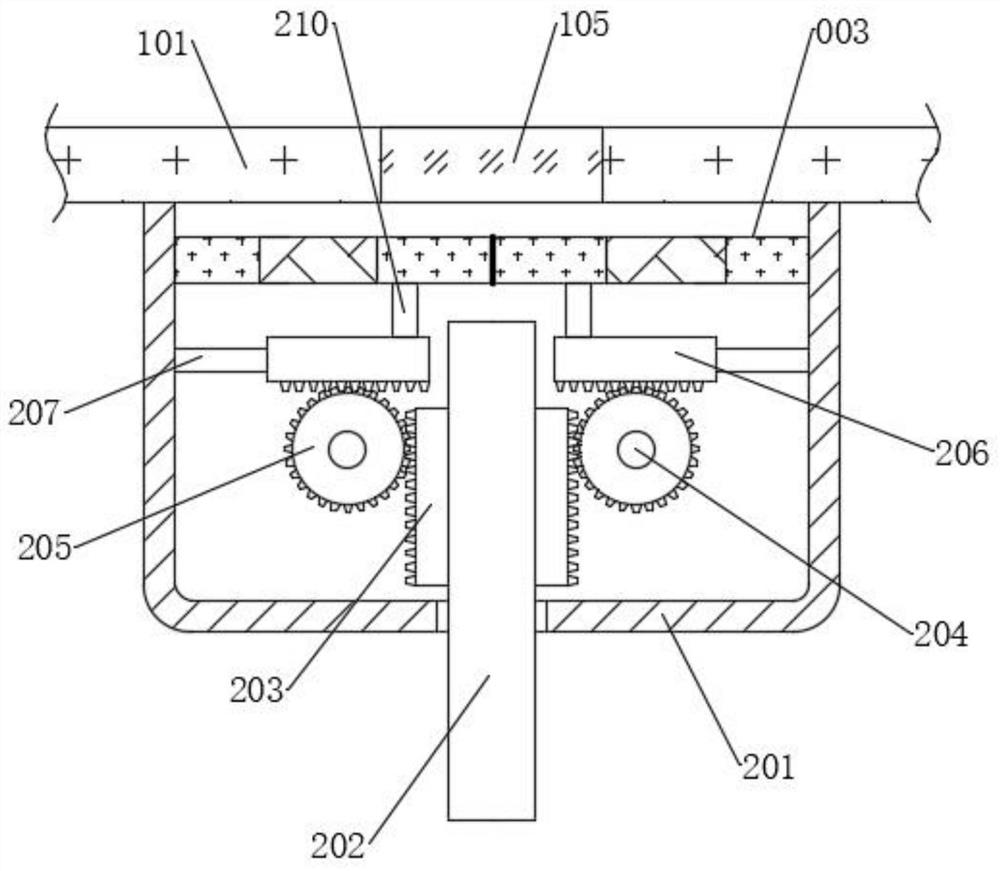

[0041] see Figure 1-7 , an automobile parts processing device, comprising two semi-heating bodies 001, the semi-heating body 001 is formed by sealing and combining a body shell 101 and a body lining 102 with matching shapes, and the body shell 101 is heat-insulated material, the body lining 102 is made of thermally conductive material, a half-cavity is arranged in the half-heater body 001, and the whole cavity composed of the half-cavities of the two half-heater bodies 001 is compatible with the automobile parts to be annealed Matching, so that after the auto parts to be annealed are put into the semi-heating body 001, the body lining 102 can be closely attached to the auto parts, so that the auto parts are heated evenly, and the gap between the body shell 101 and the body lining 102 A sealed uniform groove 103 is arranged between them, and the uniform groove 103 is filled with a rheological heating body 104. The bottom end of the body shell 101 is inlaid with a heat conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com