Laser annealing device and method

A technology of laser annealing and laser irradiation, which is used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven temperature distribution and annealing effect on the surface of silicon wafers, ensure the uniformity of annealing temperature, and improve the annealing effect. Uniformity, yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

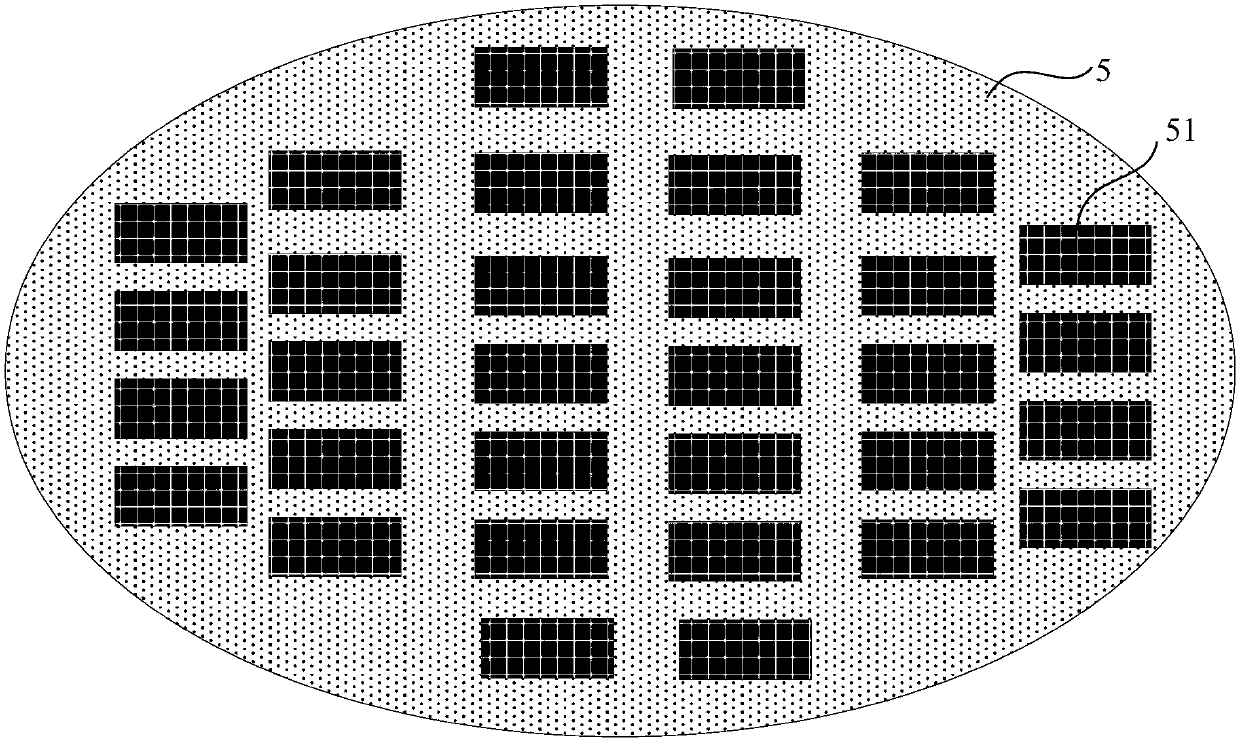

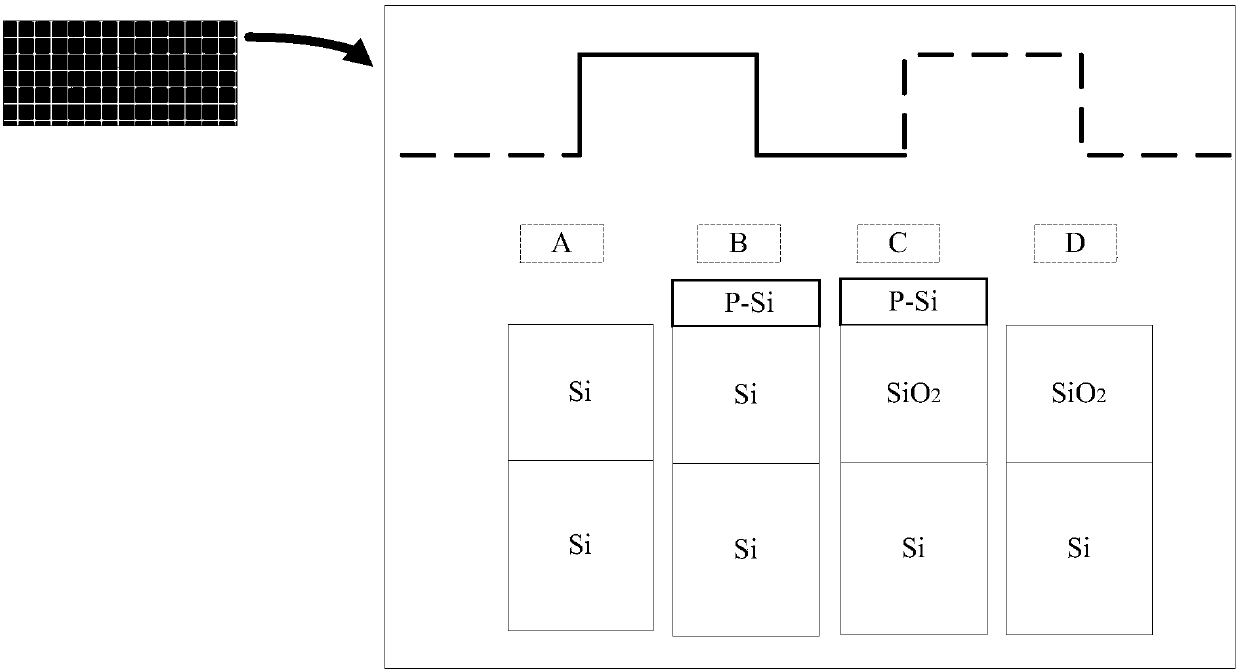

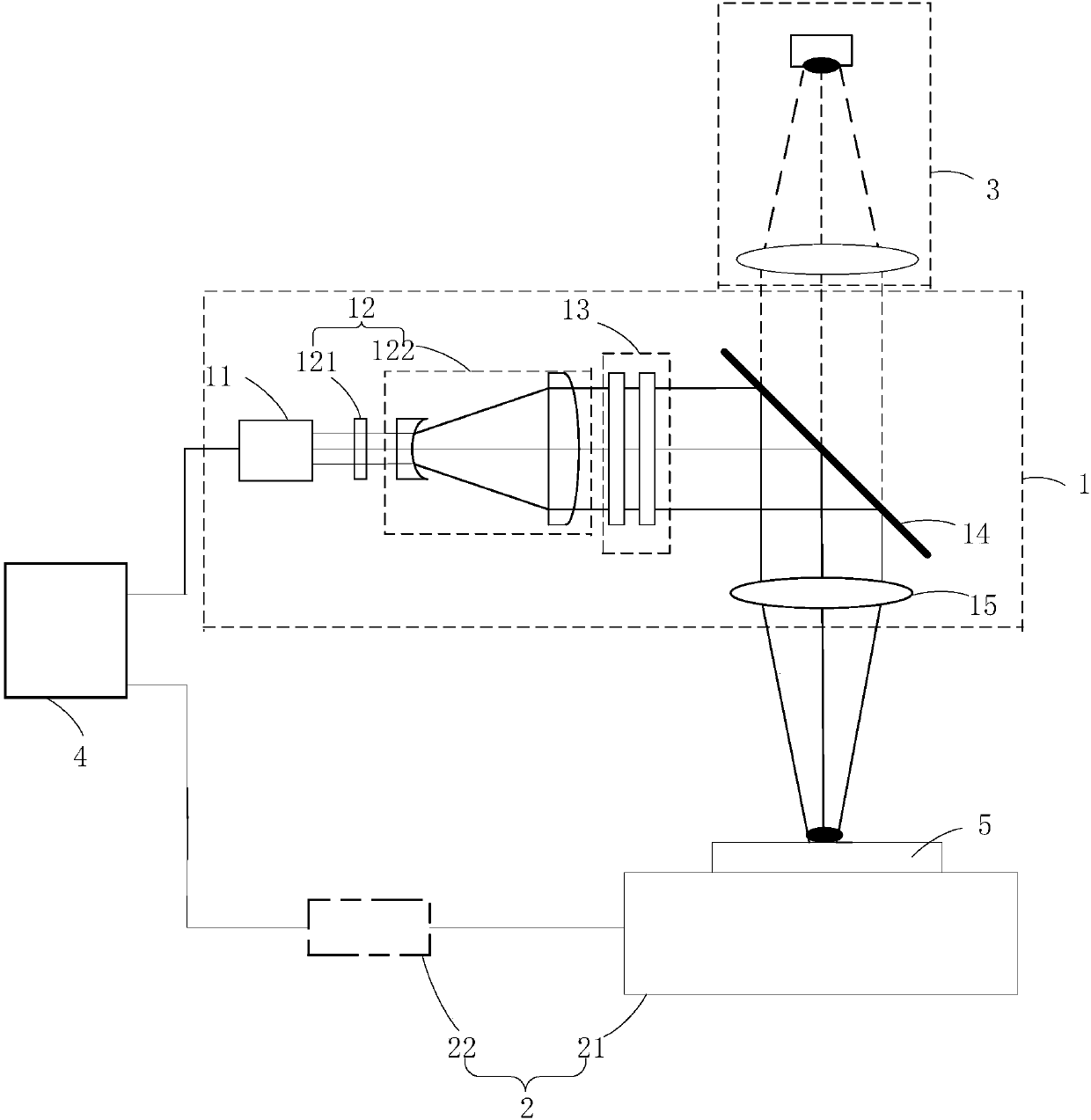

[0052] Such as image 3 As shown, the present invention provides a laser annealing device, including a laser irradiation system 1, a slide system 2, and a reflected light detection system 3 arranged sequentially along the optical path, as well as the laser irradiation system 1, the slide system 2, and the reflected light detection system. The host 4 connected to the detection system 3; the laser irradiation system 1 includes a laser light source 11, a beam adjustment component 12, a light intensity distribution forming component 13, a beam splitting component 14 and a focusing component 15 arranged sequentially along the optical path;

[0053] The laser light emitted by the laser light source 11 sequentially passes through the beam adjustment component 12, the light intensity distribution forming component 13, the beam splitting component 14 and the focusing component 15, and then projects onto the silicon wafer 5 of the slide system 2, and the reflected beam sequentially Afte...

Embodiment 2

[0069] The difference from Embodiment 1 is that in this embodiment, the light intensity distribution forming assembly 13 includes a turntable 131 and a number of transmittance compensation plates or a number of mask plates (that is, mask plates with A specific transmission pattern, so that the light beam irradiated on the mask passes through the mask plate according to the specific transmission pattern to form a corresponding light intensity distribution). Specifically, the transmittance compensation plate or mask plate is customized according to the surface topography of the actual annealed silicon wafer 5, that is, the surface of the silicon wafer 5 is irradiated with a uniform laser beam, and the energy of the reflected beam detected by the reflected light detection system 3 Distributed calculation of the reflectance of the surface of the silicon wafer 5, thereby obtaining the absorptivity of the surface of the silicon wafer 5, and calculating the light intensity distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com