Method for eliminating stress and damage in producing monolithic photoelectric integrated receiver

A technology of optical receiver and photoelectric integration, applied in the field of optoelectronics, to achieve the effect of easy operation, not easy to stain, and improved annealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

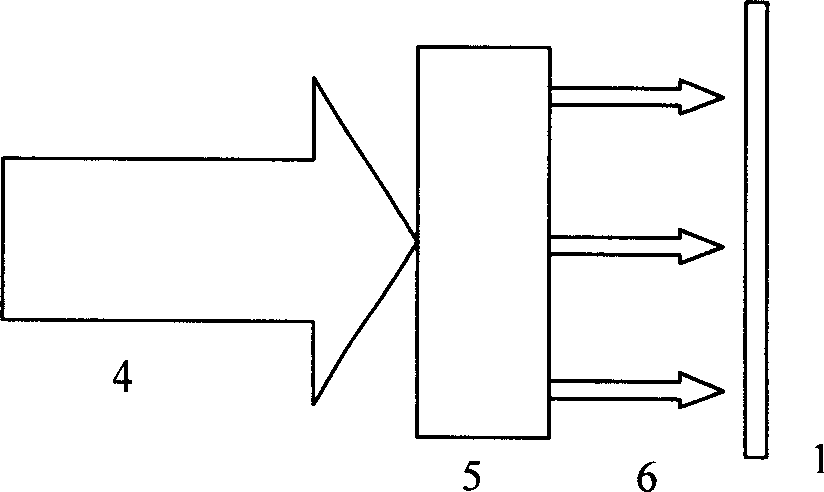

[0035] According to the annealing method provided by the present invention, a laser local annealing device (as attached Figure 4 shown), it is made up of a laser 7, a reflector 8, a lens 9, a substrate 10, a three-dimensional adjustment platform 11, a temperature measuring device 12, and a window 13 for transmitting laser light; the substrate 10 that has undergone ion implantation process is placed in On the three-dimensional adjustment table 11, the laser light emitted by the laser 7 is reflected by the mirror 8, and then focused by the lens 9 and irradiated on the substrate 10 for annealing to eliminate stress and damage after ion implantation. Adjusting the three-dimensional adjusting stage 11 through the window 13 for transmitting laser light can make the laser beam align with a certain photodiode area on the substrate. The annealing temperature can be measured by the temperature measuring device 12, and can be adjusted by adjusting the power of the incident laser beam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com