Hydrogen annealing furnace for bright heat treatment production line

A production line and annealing furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., to achieve the effects of high annealing efficiency, simple structure, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

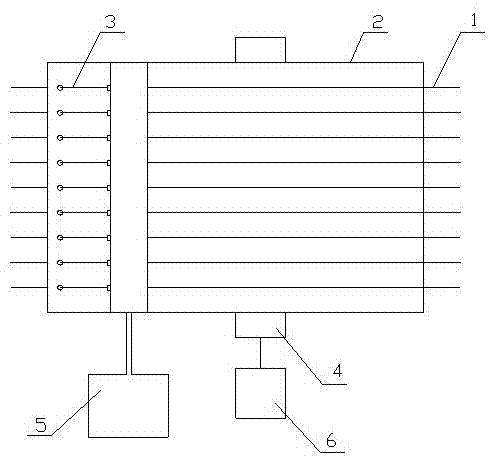

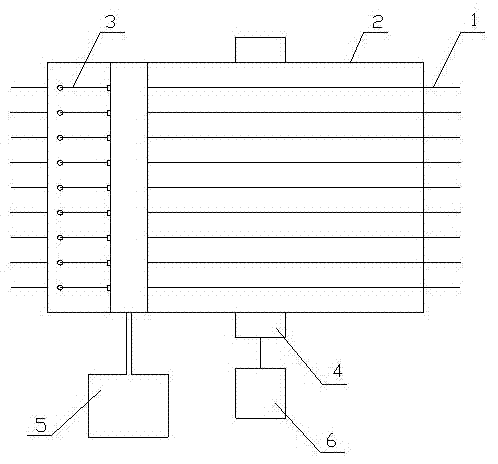

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Example figure 1 As shown, the present embodiment provides a hydrogen annealing furnace for a bright heat treatment production line, including a furnace body, nine channel pipes, nine air pipes, resistance wires, gas sources and power supplies; the furnace body is strip-shaped, and the length is eight meters. Or other lengths can be selected according to annealing requirements. The outer wall of the furnace body is provided with an insulating layer. The gas source is a mixed gas of three parts hydrogen and one part nitrogen, or a gas without oxygen. The pressure of the gas source is greater than normal pressure. The channel tube is made of oxygen-free seamless stainless steel tube. Nine channel tubes run through the furnace body in parallel. One end of each gas tube is connected to the radial conduction of the corresponding channel tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com