Electric heating film, electric heating plate and corresponding manufacturing methods

A manufacturing method and electrothermal film technology, applied in the direction of electrothermal devices, ohmic resistance heating, electrical components, etc., can solve the problems of long warm-up time, low electrothermal conversion efficiency, short service life, etc., and achieve high electrothermal conversion efficiency, that is, heat capacity Small, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

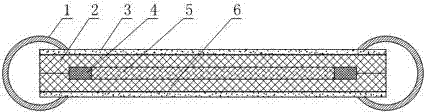

[0026] An electrothermal film, comprising a base material 6 for carrying and insulation, and a heat-generating coating applied on the base material 6, the heat-generating coating comprises an adhesive and a carbon heat-generating material, and the carbon heat-generating material is Carbon powder with a mesh number between 5000 and 10000 meshes, the carbon powder is made by mixing carbon black powder and graphite powder, and the mass ratio of the carbon black powder and graphite powder is between 1:1 to 1:4 between.

[0027] In this embodiment, the heating material is carbon-based and preferably a mixture of carbon black and graphite. The reason is that the resistance of carbon black usually has a positive temperature coefficient, and the surface graphite usually has a negative temperature coefficient below 700°C. Mixing in a ratio of 1:1 to 1:4 can keep the temperature coefficient of the heating film of the carbon heating material with different powers within an appropriate ra...

Embodiment 2

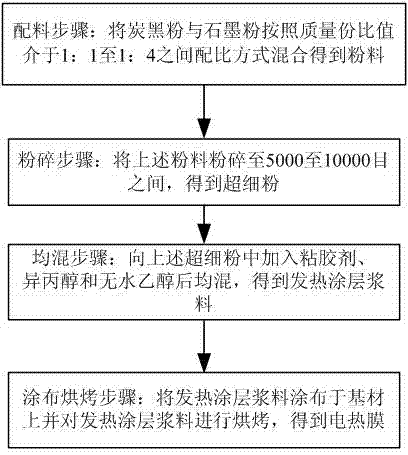

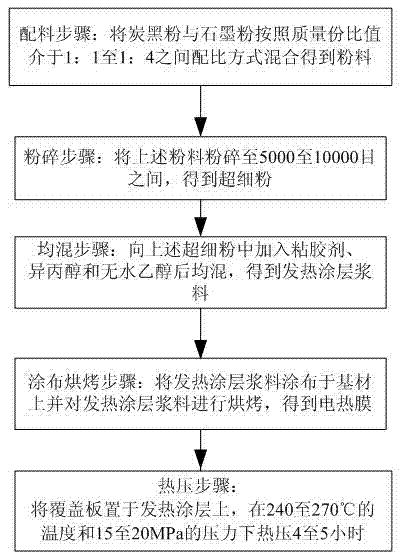

[0030] This embodiment provides a manufacturing method for the electrothermal film described in Embodiment 1, such as figure 2 As shown, the manufacturing method includes the following steps performed in sequence:

[0031] A, batching step: mix carbon black powder and graphite powder according to the ratio of mass parts between 1:1 and 1:4 to obtain powder;

[0032] B, pulverizing step: above-mentioned powder material is pulverized to between 5,000 to 10,000 meshes to obtain ultrafine powder;

[0033] C, uniform mixing step: after adding viscose to above-mentioned ultrafine powder, uniform mixing obtains heating coating slurry;

[0034] D. Coating and baking step: coating the heating coating slurry on the substrate 6 and baking the heating coating slurry to obtain the electric heating film 5 .

[0035] As a preferred measure of the manufacturing method, in step C, it also includes adding isopropyl alcohol and anhydrous ethanol to the ultrafine powder and mixing them uniform...

Embodiment 3

[0038] This embodiment is further limited on the basis of Embodiment 1. As a further preferred limitation on the components of the electrothermal film, the heat-generating coating further includes fillers and stabilizers. The fillers, stabilizers, adhesives, and carbon heat-generating materials Mix uniformly, the filler is one or more of talc powder, titanium dioxide powder, silica powder, muscovite powder, sericite powder, ore powder; the adhesive agent is inorganic adhesive agent, organic adhesive agent , one or more of organic silicon adhesive and organic fluorine adhesive; the stabilizer is one or more of heat stabilizer, antioxidant, coupling agent and cross-linking agent.

[0039] The adhesive is a silicone adhesive, and the mass ratio of the adhesive to the carbon heating material is between 1:2 and 1:3; the filler is talcum powder, and the mass ratio of the filler to the carbon heating material is between 1:2 and 1:3; The ratio is not greater than 10; the stabilizer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com