Fast heat treatment method for controlling magnetic property of double-roller thin-strip casting non-oriented silicon steel

A twin-roll thin strip continuous casting and rapid heat treatment technology, applied in the field of metallurgy, can solve the problems of less research on control methods, affecting the magnetic properties of non-oriented silicon steel, etc., to achieve the easy realization of rapid heat treatment technology, obvious magnetic properties of products, and rapid heat treatment. technically simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

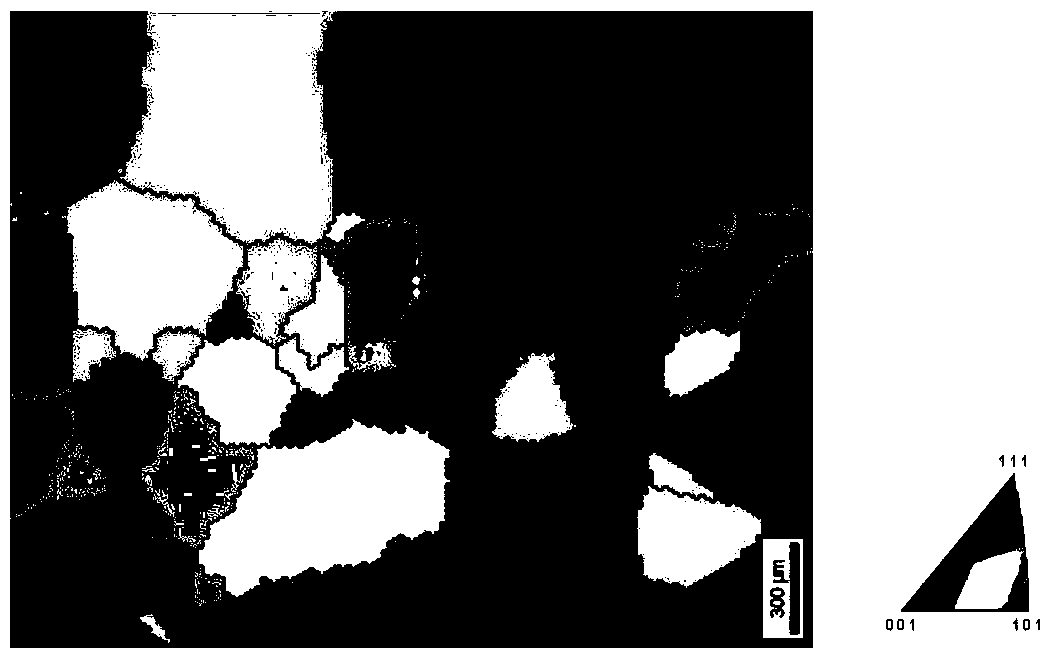

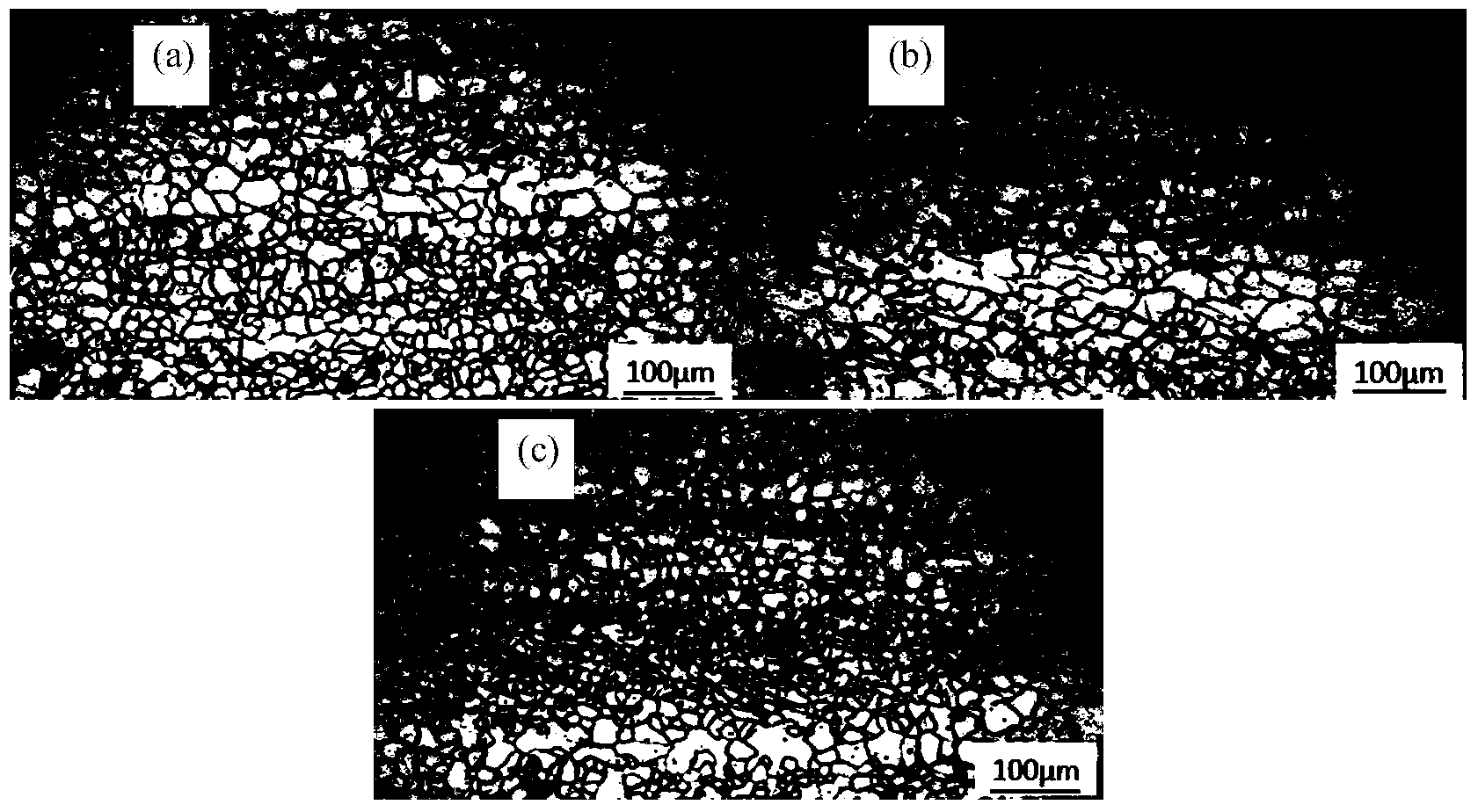

[0023] 1. Non-oriented silicon steel is prepared according to the mass percentage of chemical composition: C: 0.0032%, Si: 1.39%, Mn: 0.20%, Al: 0.32%, O: 0.0043%, S: 0.004%, N: 0.0072%, and the rest is Fe and unavoidable impurities; the non-oriented silicon steel is smelted into molten steel, the pouring temperature is controlled at 1560±2°C, and the molten steel is poured into the molten pool of the twin-roll strip continuous casting machine through the tundish, and the molten pool is formed by the rotating steel roll Composed of side sealing plates, the molten steel solidifies and forms rapidly after contacting the crystallized roll surface of the steel roll, and a cast strip with a thickness of 2.5±0.3mm is obtained. The cast strip structure is single-phase ferrite, which is uneven along the thickness direction. The surface layer is a larger columnar crystal with an average grain size of about 360 μm, such as figure 1 shown;

[0024] 2. Air-cool the cast strip to 699±1°C ...

Embodiment 2

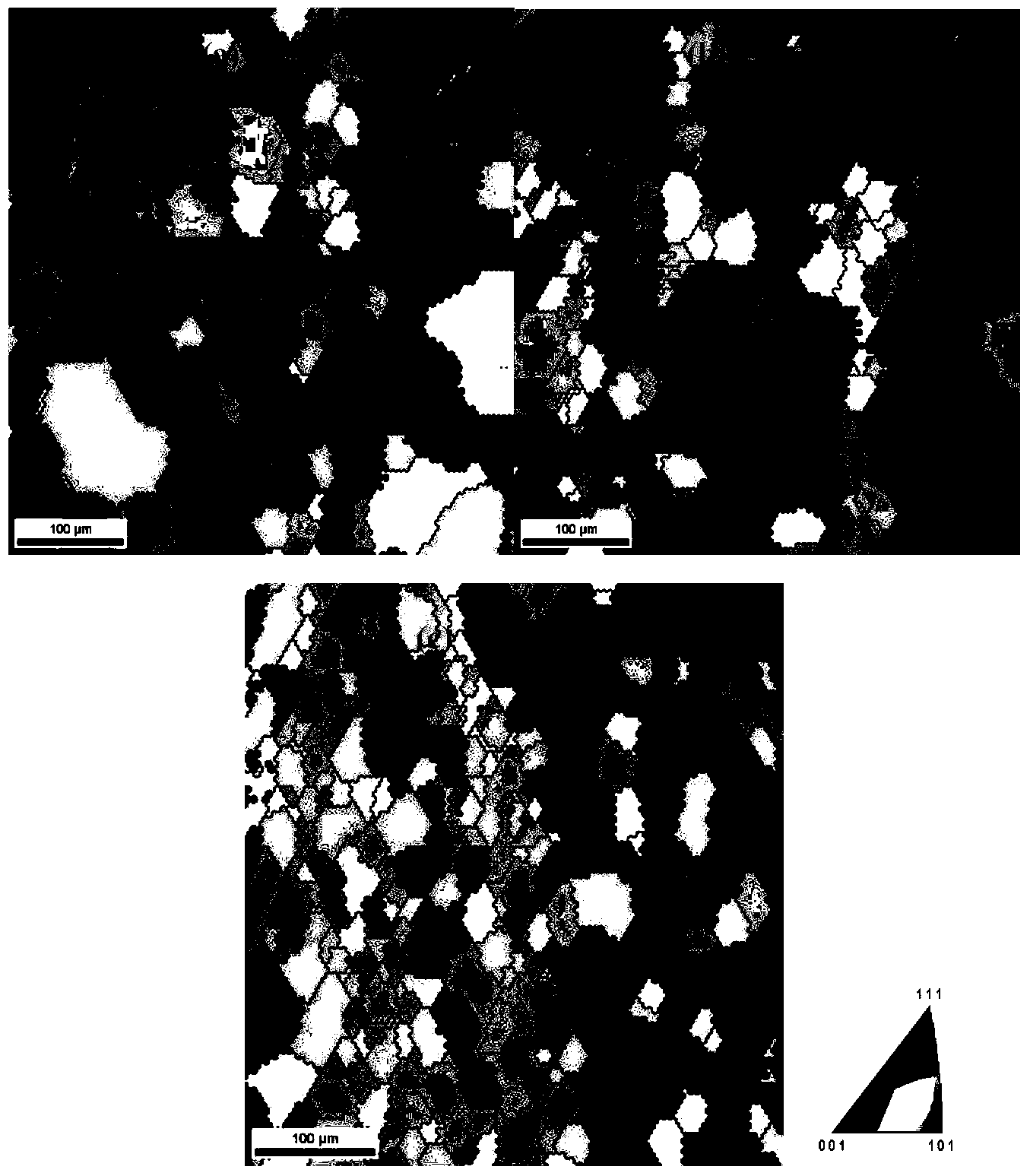

[0031]1. Non-oriented silicon steel is prepared according to the mass percentage of chemical composition: C: 0.0032%, Si: 1.23%, Mn: 0.41%, Al: 0.20%, O: 0.0043%, S: 0.0042%, N: 0.0052%, and the rest is Fe and unavoidable impurities; the non-oriented silicon steel is smelted into molten steel, the pouring temperature is controlled at 1598±2°C, and the molten steel is poured into the molten pool of the twin-roll strip continuous casting machine through the tundish, and the molten pool is formed by the rotating steel roll Composed of side sealing plates, molten steel solidifies and forms rapidly after contacting the crystalline roll surface of the steel roll, and a cast strip with a thickness of 2.5±0.1mm is obtained. The cast strip structure is single-phase ferrite, and the surface layer and the middle and lower layers are fine and equiaxed crystal, the subsurface layer is columnar crystal, the average grain size is about 400μm;

[0032] 2. Air-cool the cast strip to 601±1°C be...

Embodiment 3

[0039] 1. Non-oriented silicon steel is prepared according to the mass percentage of chemical composition: C: 0.0032%, Si: 0.52%, Mn: 0.35%, Al: 0.40%, O: 0.0043%, S: 0.0035%, N: 0.0052%, and the rest is Fe and unavoidable impurities; the non-oriented silicon steel is smelted into molten steel, the pouring temperature is controlled at 1542±2°C, and the molten steel is poured into the molten pool of the twin-roll strip continuous casting machine through the tundish, and the molten pool is formed by the rotating steel roll Composed of side sealing plates, molten steel solidifies and forms rapidly after contacting the crystallized roll surface of the steel roll, and obtains a cast strip with a thickness of 2.5±0.2mm. The cast strip structure is single-phase ferrite, and the cast strip structure is uneven. The surface layer is Fine equiaxed crystals, the subsurface layer is coarse columnar crystals, the average grain size is about 390μm;

[0040] 2. Air-cool the cast strip to 501±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com