Annealing method and device of bell type furnaces

A bell-type furnace and annealing technology, which is applied in the field of combined bell-type furnace annealing and bell-type furnace annealing, can solve the problems of non-recyclable heat, low heat transfer efficiency, high operating cost, etc., to save equipment investment and operating costs, The effect of good operational flexibility and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

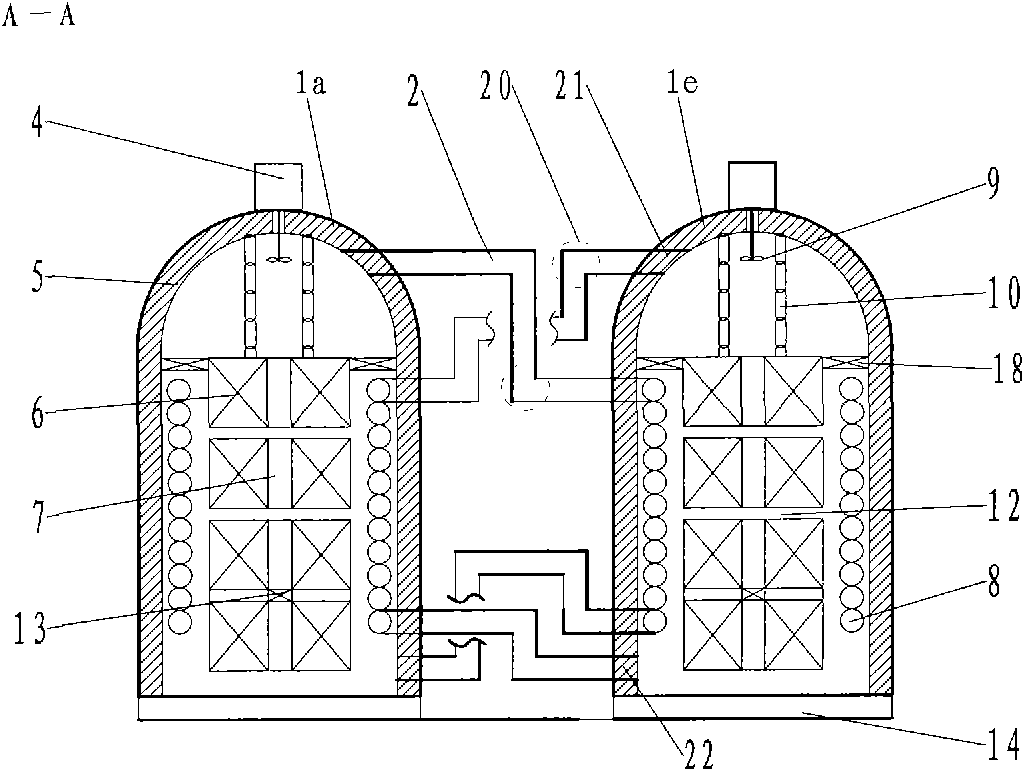

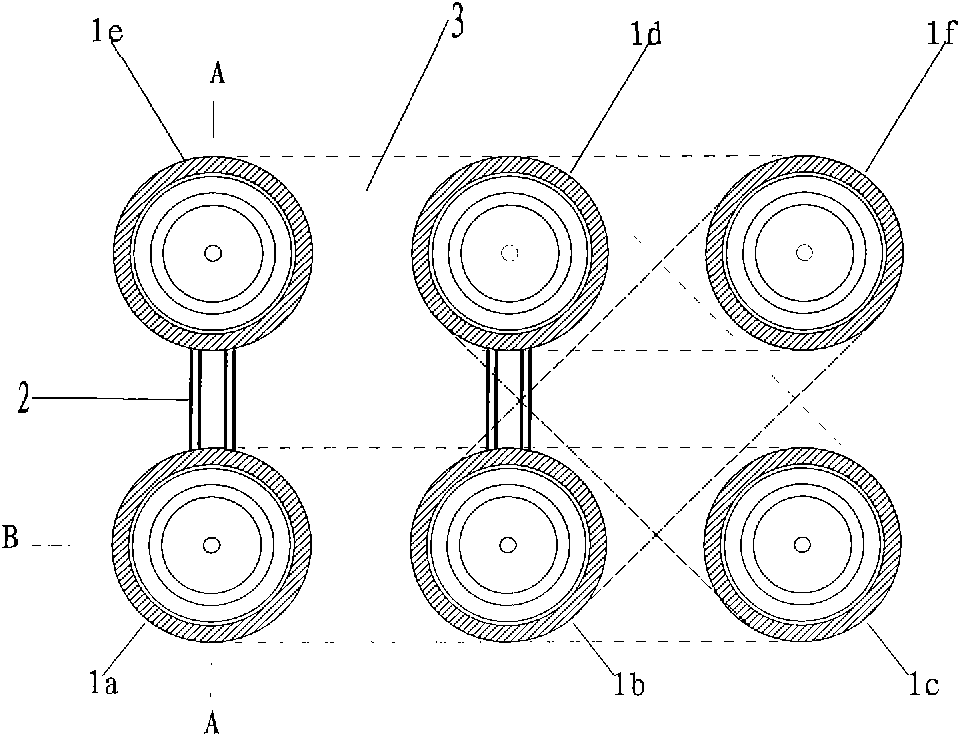

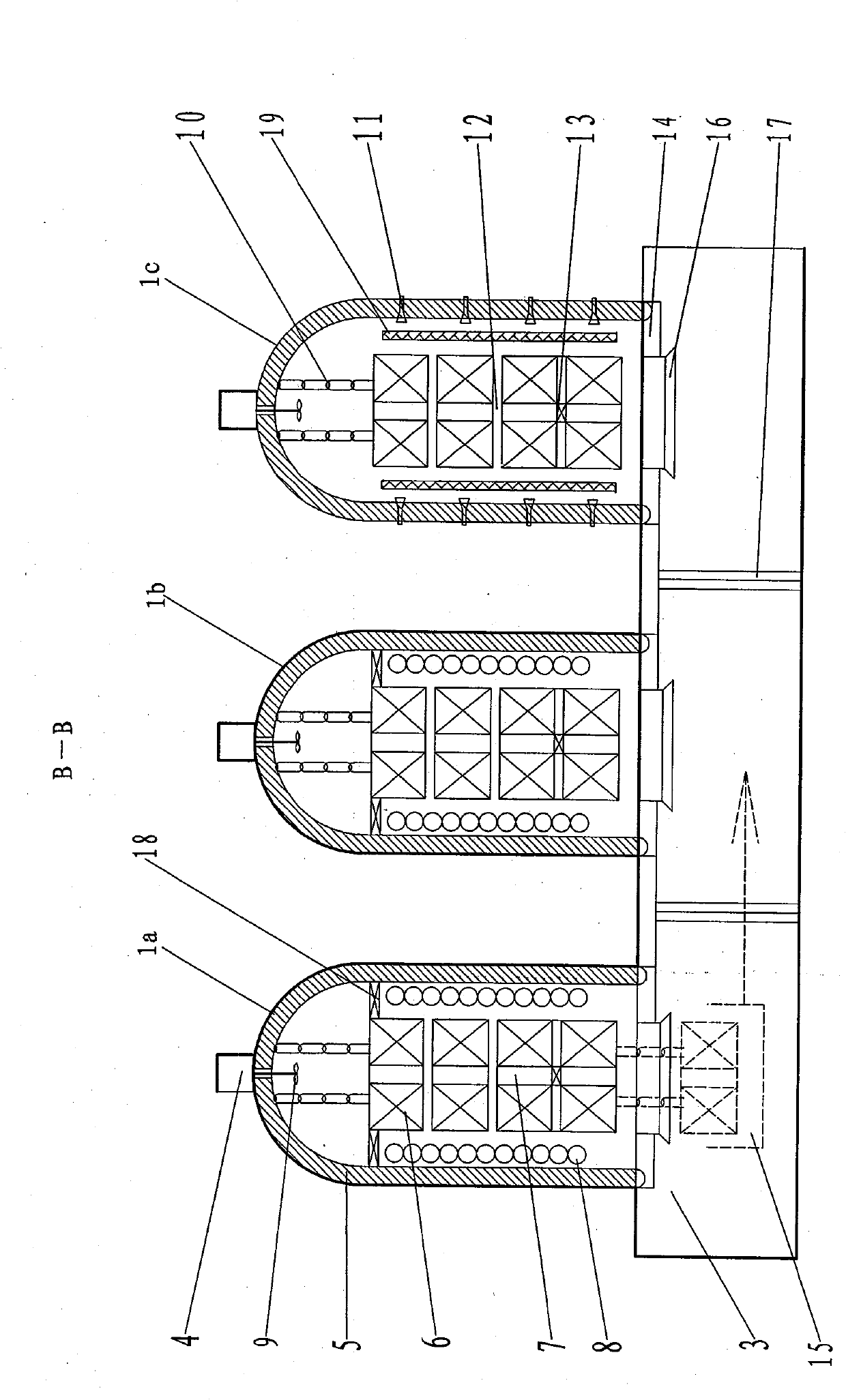

[0018] Bell furnace device of the present invention such as figure 1 , image 3 As shown, it includes a bell furnace 1 and a supporting protective gas system, a heating system and an exhaust system. The bell-type furnace is provided with a furnace cover 5 and a stove base 14, and a fan 9 and a rack are arranged in the furnace cover, and the fan is driven by a motor 4. The top of the furnace cover is provided with a chain 10 for hanging the material to be annealed. Five bell furnaces are installed in series, two preheating bell furnaces 1a, 1b, two cooling bell furnaces 1d, 1e and one heating bell furnace 1c. The lower part of each hearth is provided with a conveying channel 3 for conveying the material to be annealed, and a conveying device 15 is arranged in the conveying channel. A plug valve 17 is provided between every two bell-type furnaces in the conveying passage 3, and a sealing valve 16 is provided between the bell-type furnace body and the conveying passage. Such ...

Embodiment 2

[0021] Another embodiment of the present invention is as Figure 4 As shown, six bell-type furnaces are installed in series, two preheating bell-type furnaces 1a, 1b, two cooling bell-type furnaces 1d, 1e and one heating bell-type furnace 1c, 1f, and other structures are the same as in the embodiment. In this embodiment, a heating bell-type furnace is added. After the high-temperature preheating bell-type furnace 1b is preheated, the strip steel to be processed alternately enters the heating bell-type furnace 1c or 1f, and the heating bell-type furnace 1c or 1f completes heating and heat preservation. After the process, the strip steel is sequentially transported to the high-temperature cooling bell furnace 1d, cooled to 440-450°C, and continued to cool to 220-230°C in the low-temperature cooling bell-type furnace 1e, and discharged through the discharging equipment. Other operations and process conditions are identical with embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com