Laser annealing device

A laser annealing and laser beam technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of low crystal absorption energy, inability to meet, low annealing efficiency, etc., to achieve good uniformity, high annealing efficiency, high The effect of the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

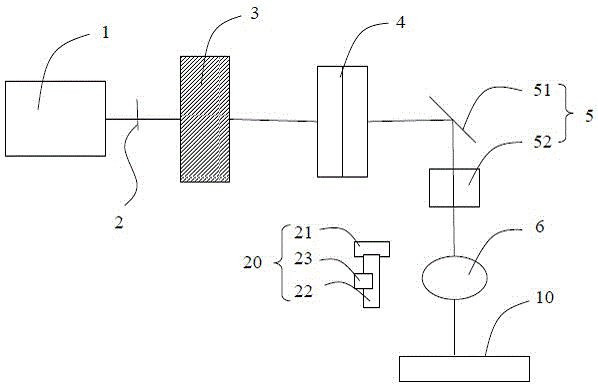

[0023] Please refer to figure 1 Shown is a schematic diagram of the overall structure of the laser annealing device of the present invention, including: a laser source 1, optical components, an image positioning system 20 and a control system. The laser beam emitted by the laser source 1 is adjusted and converted by the optical elements in the optical assembly to irradiate a flat-top spot with balanced energy. The flat-top spot has the advantages of high annealing efficiency and good uniformity, and at the same time improves the stability of the crystal arrangement. Activation rate, with higher proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com