Soil conditioner prepared by activating phosphate rock tailings by using organic/inorganic activators and preparation method thereof

A technology of inorganic activator and soil conditioner, applied in fertilizer mixtures, fertilization devices, applications, etc., to achieve the effects of slowing down phytotoxicity, alleviating pollution, and enhancing stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

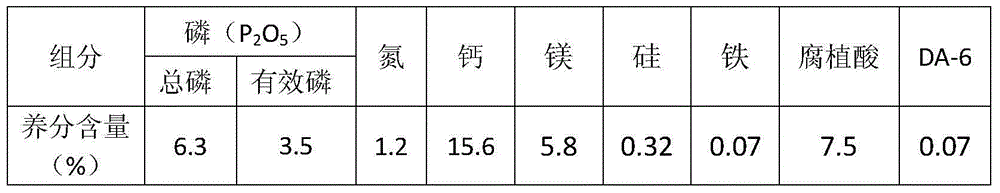

Embodiment 1

[0043] 1. Source of raw materials:

[0044] Phosphate ore tailings: Guizhou Wengfu Group flotation mine tailings, with a total phosphorus content of 8.4wt%;

[0045] Lignite: Shanxi Lvliang lignite raw powder, total acid content (dry basis) 50wt%;

[0046] DA-6 (diethylhexanoate): commercially available, with a purity of 99%

[0047] A soil conditioner for activating phosphate rock tailings with organic and inorganic activators, the composition of which is as follows in parts by weight of raw materials:

[0048] 75 parts of phosphate rock tailings powder, 20 parts of lignite, 5 parts of urea and ammonium bicarbonate; 0.1 part of diethyl diethyl ethyl DA-6. The mass ratio of urea to ammonium bicarbonate is 1:1.

[0049] 2. Preparation of soil conditioner:

[0050] (1) Pulverizing the phosphate rock tailings to obtain the phosphate rock tailings powder, mixing and grinding the phosphate rock tailings powder and lignite for 5 minutes according to the proportioning ratio,

[...

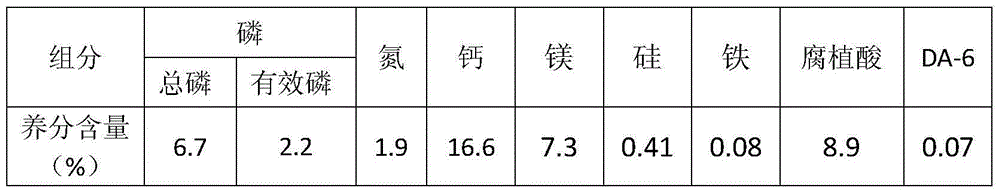

Embodiment 2

[0057] 1. Source of raw materials:

[0058] Phosphate ore tailings: flotation mine tailings of Guizhou Wengfu Group, with a phosphorus content of 8.5wt%;

[0059] Weathered coal: Inner Mongolia Wuhai weathered coal raw powder, total acid content (dry basis) 55.8%;

[0060] DA-6 (diethylhexanoate): commercially available, with a purity of 99%

[0061] A soil conditioner for activating phosphate rock tailings with organic and inorganic activators, the composition of which is as follows in parts by weight of raw materials:

[0062] 85 parts of phosphate rock tailings powder, 20 parts of weathered coal, 5 parts of urea and ammonium bicarbonate; 0.07 parts of diethyl diethylhexanoate DA-6. The mass ratio of urea to ammonium bicarbonate is 1:1.

[0063] 2. Preparation of soil conditioner:

[0064] (1) Pulverize the phosphate rock tailings to obtain the phosphate rock tailings powder, mix and grind the phosphate rock tailings powder and weathered coal for 10 minutes according to ...

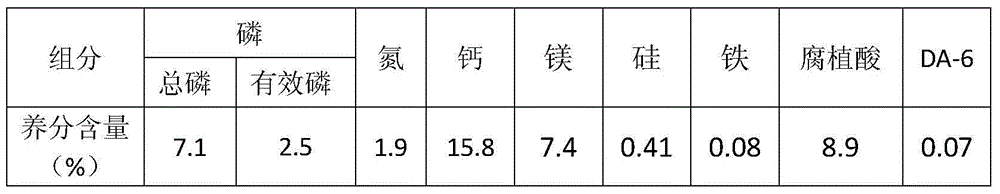

Embodiment 3

[0071] 1. Source of raw materials:

[0072] Phosphate ore tailings: flotation mine tailings from Yunnan Zhongzheng Company, with a phosphorus content of 7.5wt%;

[0073] Humic acid and weathered coal: commercially available humic acid, raw powder of weathered coal in Hami, Xinjiang, total acid content (dry basis) 61.8wt%;

[0074] DA-6 (diethylhexanoate): market purchase, purity 99%

[0075] A soil conditioner for activating phosphate rock tailings with organic and inorganic activators, the composition of which is as follows in parts by weight of raw materials:

[0076] 70 parts of phosphate rock tailings powder, 20 parts of humic acid and weathered coal, 3 parts of urea and ammonia water, the concentration of ammonia water is 25wt%; diethyl diethyl ethyl DA-6 0.07 parts. The mass ratio of urea to ammonia water is 1:1.

[0077] 2. Preparation of soil conditioner:

[0078] (1) Pulverize the phosphate rock tailings to obtain the phosphate rock tailings powder, mix and grind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com