Pure-oxygen-atmosphere annealing device and method

An annealing device, technology of oxygen atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

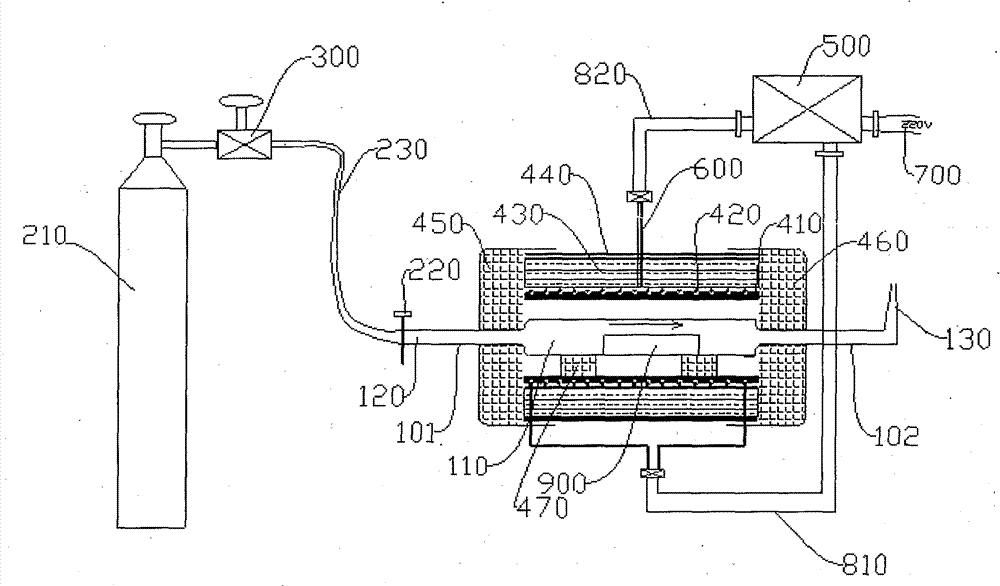

Image

Examples

Embodiment 1

[0045] Embodiment 1: adopt the device annealing Nd of the present invention: YAG crystal

[0046] Gently pull out the round stainless steel side cover lined with thermal insulation material from the annealing furnace, put the Nd:YAG crystal, wafer or ingot into the quartz tube, then seal the furnace tube with the side cover, and turn on the oxygen in sequence Bottle switch and oxygen decompression valve switch, the flow of pure oxygen is controlled through the oxygen decompression valve and valve, so that the pressure in the quartz tube is less than 1.2atm. The temperature controller is set at a heating rate of 60°C / h, the temperature is raised to 1300°C, the temperature is kept constant for 1200min, the cooling rate is 60°C / h, and the temperature controller is operated. After the program cools down to less than 200°C, close the program, the temperature drops below 50°C, open the furnace tube, take out the crystal, wafer or ingot, close the furnace tube, and the annealing is o...

Embodiment 2

[0047] Embodiment 2: using the device of the present invention to anneal Cr4+: YAG crystal

[0048] Gently pull out the round stainless steel side cover lined with thermal insulation material from the annealing furnace, put Cr4+:YAG crystals, wafers or ingots into the quartz tube, then seal the furnace tube with the side cover, and turn on the oxygen in sequence Bottle switch and oxygen decompression valve switch, the flow of pure oxygen is controlled through the oxygen decompression valve and valve, so that the pressure in the quartz tube is less than 1.2atm. The temperature controller is set at a heating rate of 50°C / h, the temperature is raised to 1300°C, the temperature is kept constant for 3000 minutes, the cooling rate is 50°C / h, and the temperature controller is operated. After the program cools down to less than 200°C, close the program, the temperature drops below 50°C, open the furnace tube, take out the crystal, wafer or ingot, close the furnace tube, and the anneal...

Embodiment 3

[0049] Embodiment 3: using the device of the present invention to anneal Yb:YAG crystal

[0050] Gently pull out the round stainless steel side cover lined with thermal insulation material from the annealing furnace, put the Yb:YAG crystal, wafer or ingot into the quartz tube, then seal the furnace tube with the side cover, and turn on the oxygen in sequence. Bottle switch and oxygen decompression valve switch, the flow of pure oxygen is controlled through the oxygen decompression valve and valve, so that the pressure in the quartz tube is less than 1.2atm. The temperature controller is set at a heating rate of 60°C / h, the temperature is raised to 1300°C, the temperature is kept constant for 1200min, the cooling rate is 60°C / h, and the temperature controller is operated. After the program cools down to less than 200°C, close the program, the temperature drops below 50°C, open the furnace tube, take out the crystal, wafer or ingot, close the furnace tube, and the annealing is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com