Sapphire crystal growth furnace

A crystal growth furnace and sapphire technology, which is applied in the field of LED substrate-level sapphire crystal growth, can solve the problems of low material utilization rate, low crystal growth yield, high production energy consumption and cost, and reduce production costs and increase crystal formation rate , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

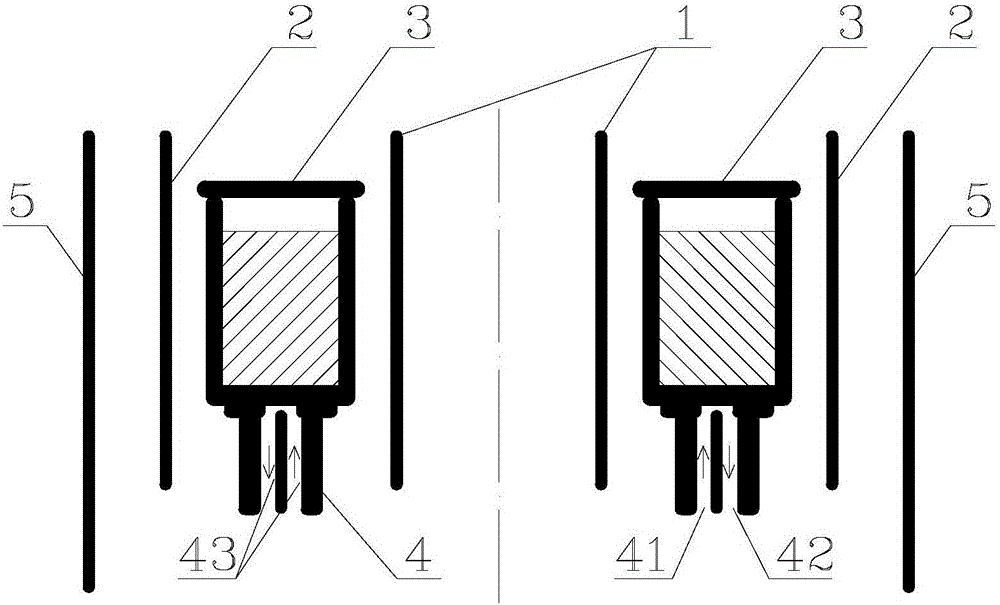

[0019] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

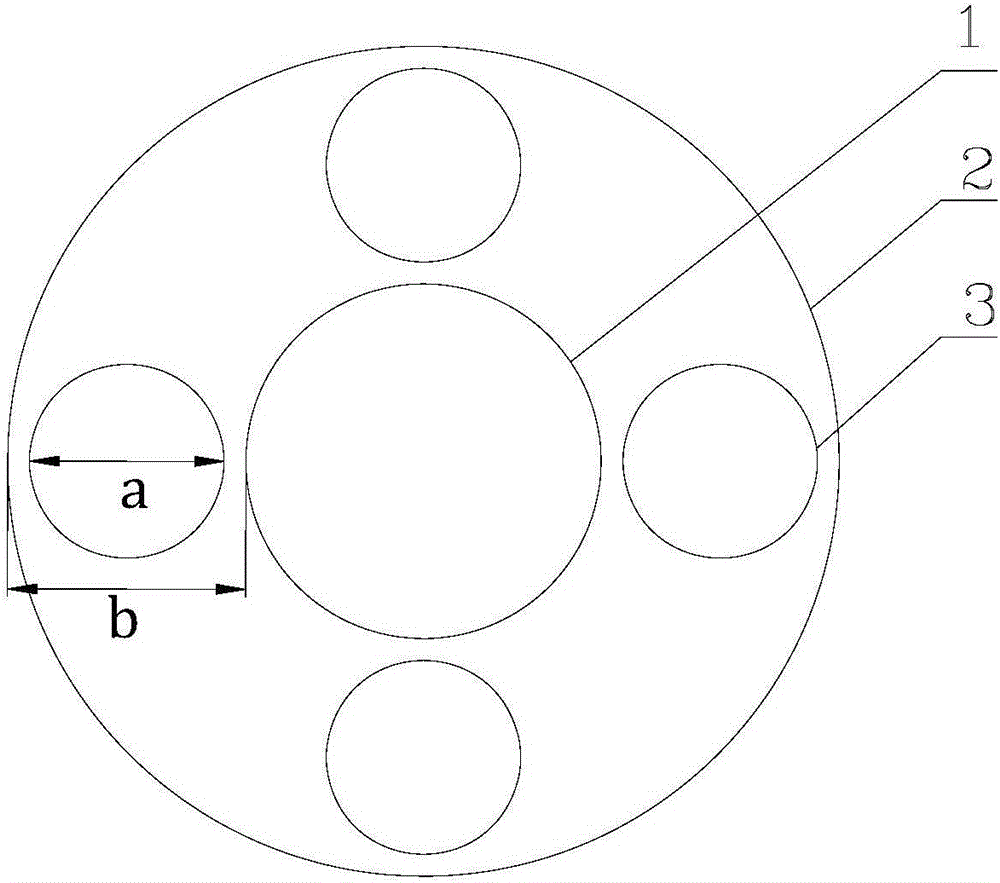

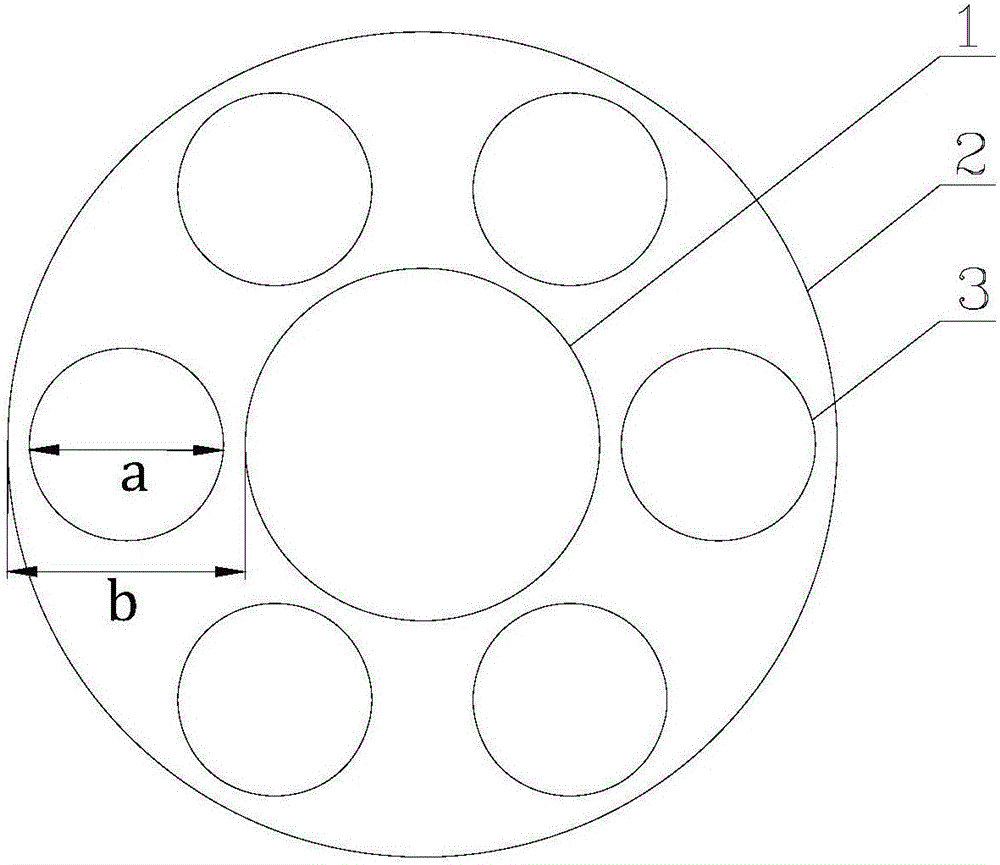

[0020] Such as Figure 1-3 As shown, a kind of sapphire crystal growth furnace of the present invention comprises annular inner heater 1 and outer heater 2, and inner heater 1 is positioned at outer heater 2 inside, and inner heater 1 and outer heater 2 are two kinds of different diameter ring-shaped tungsten heater, multiple charging crucibles 3 can be evenly arranged between the inner heater 1 and the outer heater 2, and the crucible 3 uses a tungsten crucible to grow multiple crystals at the same time. The inner and outer heaters 1 and 2 make the crucible 3 It is heated all around, and heaters can also be added on the top, and the bottom can dissipate heat to form a stable a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com