Roller kiln

A roller kiln and rail technology, applied in the furnace type, furnace, charge composition/state, etc., can solve the problems of reduced production efficiency, long ceramic cooling time, easy accumulation of ceramic raw materials, etc., to improve production efficiency and improve annealing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

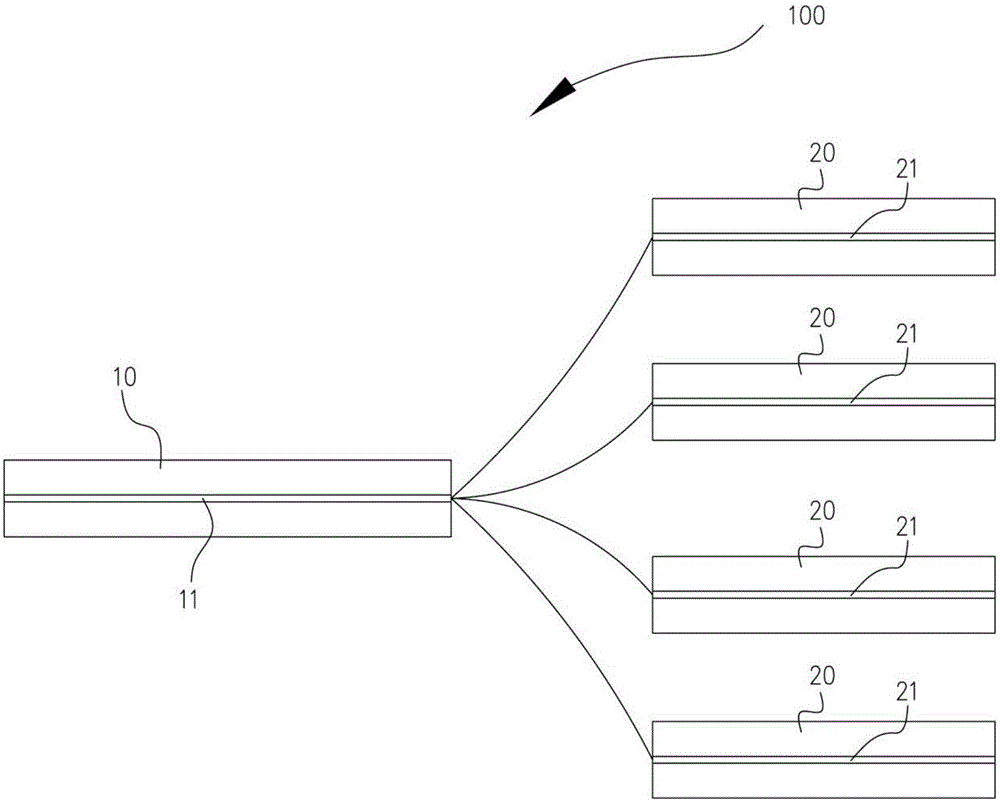

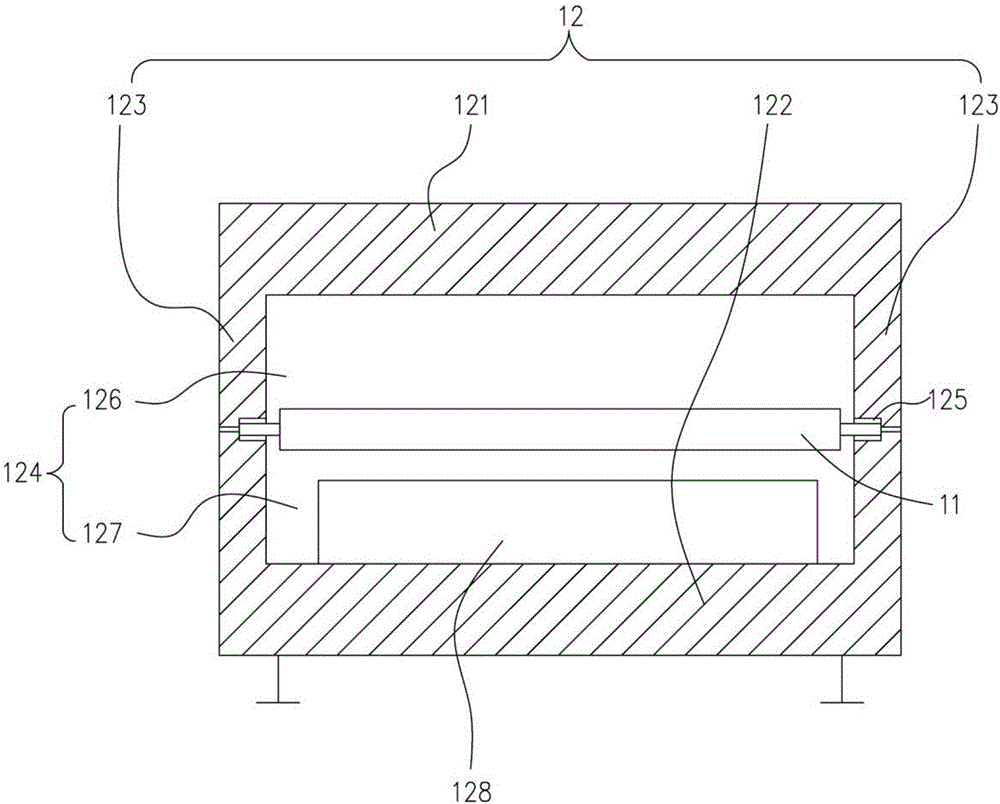

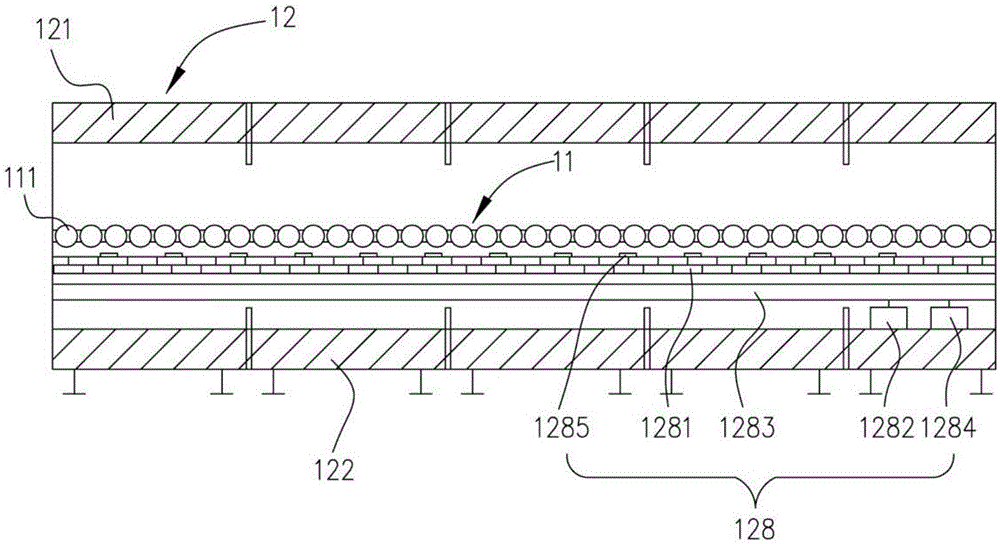

[0027] Please also refer to figure 1 , a roller kiln 100 provided by an embodiment of the present invention, the roller kiln 100 includes a heating zone 10 and a plurality of annealing zones 20, the heating zone 10 is provided with a heating track 11, and each of the annealing zones 20 is provided There is an annealing track 21 connected to the heating track 11. The heating track 11 is used to place ceramic raw materials. After the ceramic raw materials are heated in the heating zone 10, they are respectively transported to a plurality of the annealing tracks 11 through the heating track 11. tracks 21, and are cooled in a plurality of the annealing zones 20 respectively. It can be understood that the roller kiln 100 fires ceramic raw materials to make foamed ceramic plates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com