Aluminum alloy pipe cycle annealing treatment equipment furnace

A technology of cyclic annealing and treatment equipment, applied in heat treatment equipment, heat treatment furnace, heat treatment process control and other directions, can solve the problems of instability and uneven structure, and achieve the effect of saving use, reducing costs and improving the efficiency of annealing treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

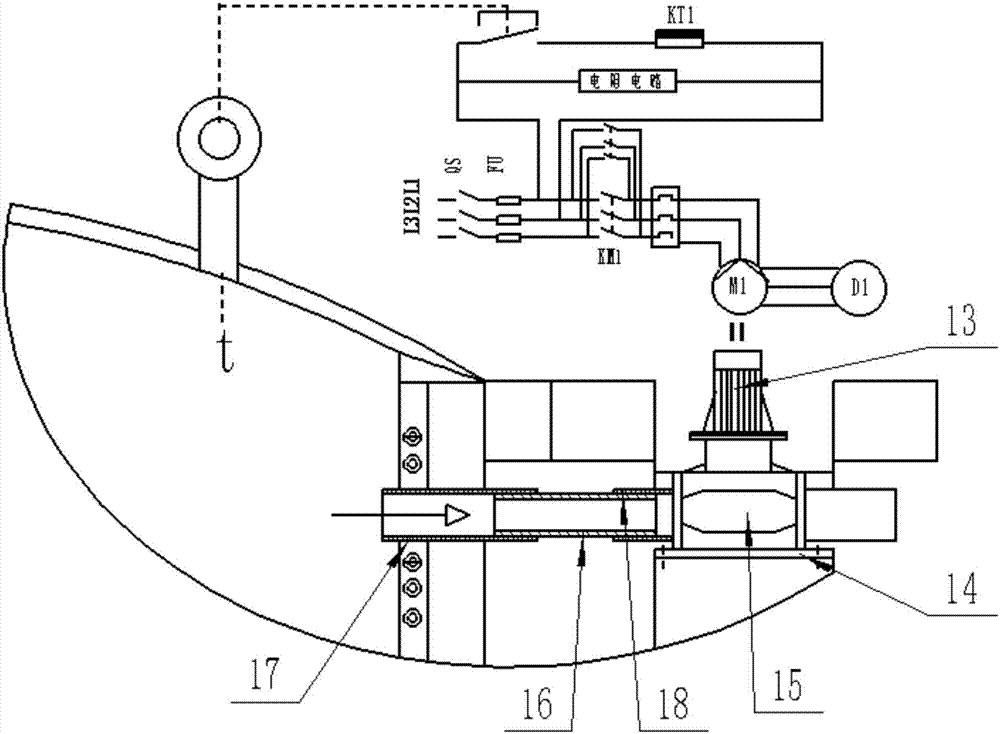

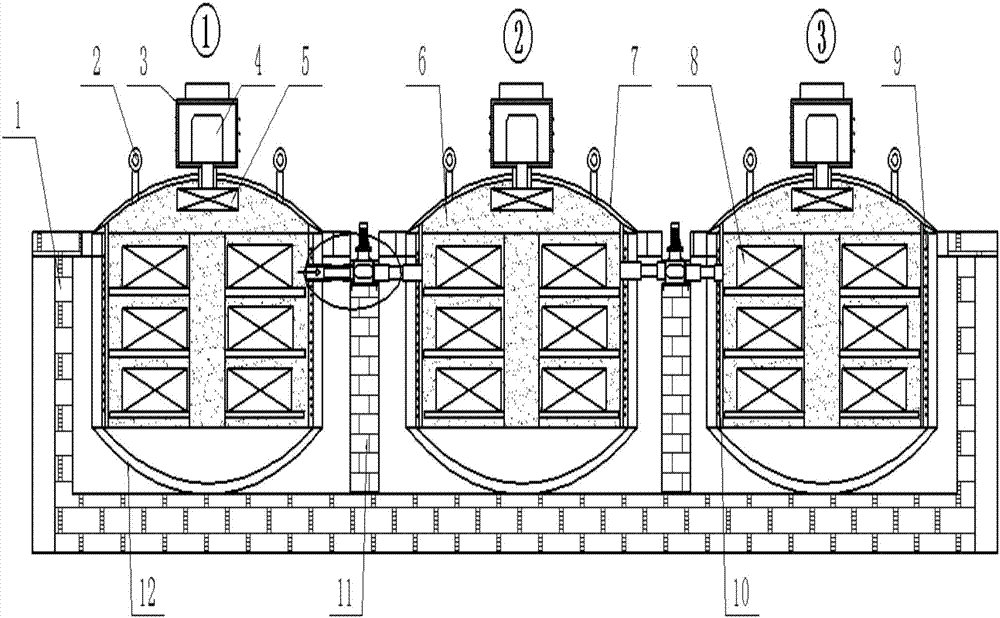

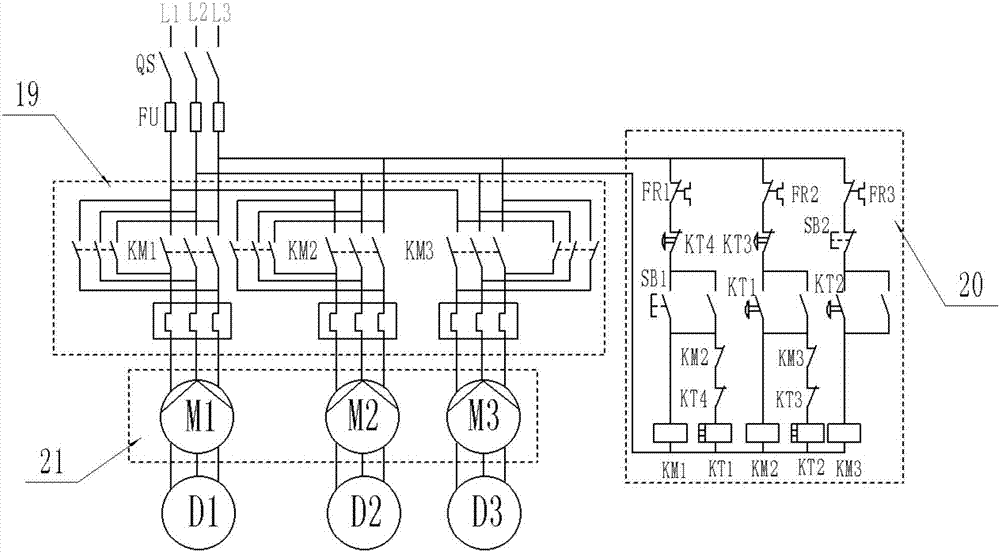

[0019] Such as Figure 1-2 As shown, the aluminum alloy tube circulation annealing treatment equipment furnace of the embodiment of the present invention mainly includes a thermal insulation foundation 1, an aluminum alloy tube coil 8, an annealing furnace 12, and three annealing furnaces 12 are arranged in parallel in the inner groove of the thermal insulation foundation 1 , carry out alternate work, can improve work efficiency, the interval position between three annealing furnaces 12 is perpendicular to the bottom of heat preservation foundation 1 and is fixed with furnace partition wall 11, and the top of three annealing furnaces 12 is equipped with detachable arc-shaped annealing furnace cover 7. A fan box 3 is installed at the center of the top of the annealing furnace cover 7, and a flow stirring motor 4 is installed inside the blower box 3. The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com