Laundry soap powder slurry, preparation method thereof and industrial production technology of laundry soap powder

A preparation method and production process technology, which is applied in the direction of chemical instruments and methods, alkali soap/ammonium soap composition, detergent powder/flake/sheet, etc., can solve the problem of large amount of dust on the production site, floating of dry sodium soap powder, Solve problems such as long dissolution time, achieve the effect of anti-caking value and fluidity improvement, uniform dispersion and adhesion state, and realize automatic packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (Slurry and its preparation process, the following percentages are weight percentages)

[0041] A laundry soap powder slurry comprises the following raw material components by weight and is prepared according to the following steps.

[0042] Raw material composition and weight percent are as follows:

[0043] Process water: 26% Regulator: 0.8%

[0044] Fatty acids: 10% Alkylbenzenesulfonic acids: 5%

[0045] Sodium sodium: 12% Yuanming powder: 28%

[0046] 4A Zeolite: 2% Surfactant: 3%

[0047] Soda ash: 8% Optical brightener: 0.1%

[0048] Sodium citrate: 2% Liquid caustic soda: calculated according to neutralization value

[0049] Slurry preparation process steps:

[0050] The process water is heated to 75°C by steam, and added to the batching kettle after metering. Liquid caustic soda is added synchronously in process water adding process, and starts stirring; Mixing), after the addition is complete, delay stirring for 20 seconds to ensure that the regulato...

Embodiment 2

[0052] (Slurry preparation process and base powder production, the following percentages are weight percentages)

[0053] A laundry soap powder slurry comprises the following raw material components by weight and is prepared according to the following steps.

[0054] Raw material composition and weight percent are as follows:

[0055] Process water: 24% Regulator: 0.6%

[0056] Fatty acids: 8% Alkylbenzenesulfonic acids: 4%

[0057] Sodium natrium: 15% Yuanming powder: 26%

[0058] 4A Zeolite: 5% Surfactant: 5%

[0059] Soda Ash: 6% Sodium Citrate: 1.5%

[0060] Liquid caustic soda: calculated according to neutralization value

[0061] Slurry preparation process steps:

[0062] The process water is heated to 70°C by steam, and added to the batching kettle after metering. The liquid caustic soda is added synchronously during the process of adding process water, and the stirring is started; the above-mentioned regulator is added in parts by weight (in this embodiment, C...

Embodiment 3

[0064] (The production process of laundry soap powder of the present invention, the following percentages are all percentages by weight)

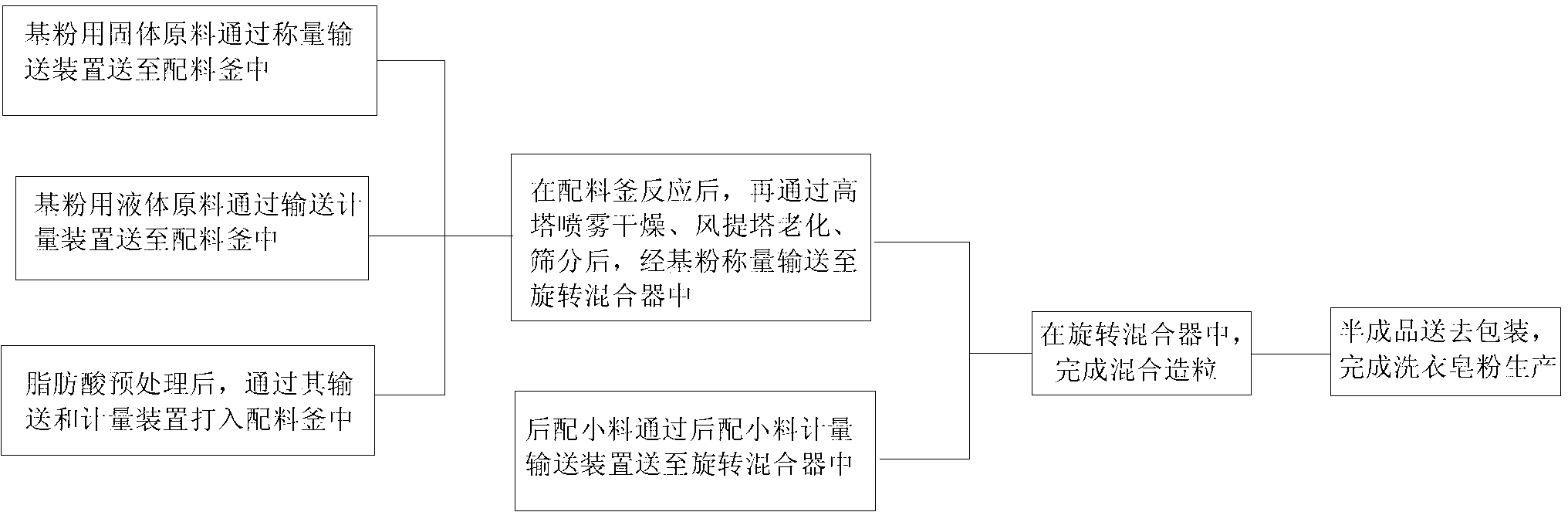

[0065] Please refer to the attached figure 1 Shown, and after carrying out the preparation of soap powder slurry according to embodiment 1 or embodiment 2, enter high tower powder spraying system, finish the atomized soap particle. The base powder coming out of the powder spraying tower is further aged, cooled and sieved by wind, conveyed by the conveyor belt and measured by the weight loss scale, and then sent to the post-equipment rotary mixer. The weight ratio of the base powder in the mixer is 84%. At the same time, it is mixed with several solid raw materials from the after-mixing system: functional small materials (enzyme preparations, functional additives) 0.9%, color particles 1.0%, zeolite 3%, soda ash 8%, The liquid material essence 0.1% and non-ionic surfactant 3% are continuously and uniformly mixed into laundry soap powder s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com